Continuous double-serrated path filling method for deposition modeling

A filling method and deposition molding technology, applied in the field of 3D printing, can solve the problems of inapplicable algorithms and unrealized global continuous filling, and achieve the effects of avoiding internal defects, saving labor costs, and improving printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

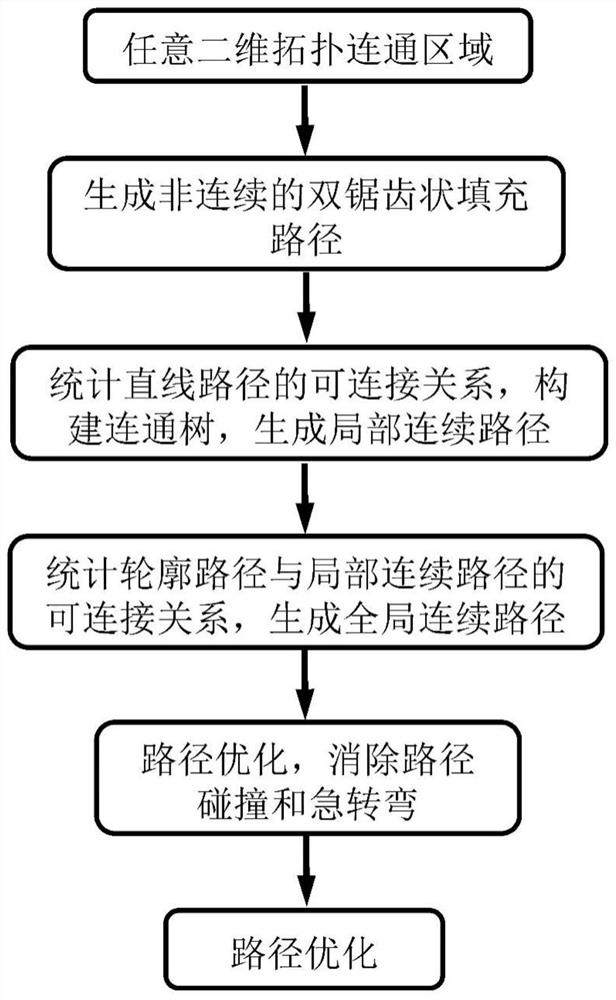

[0027] The present invention provides a continuous double zigzag path filling method (method for short) aimed at deposition molding, which comprises the following steps:

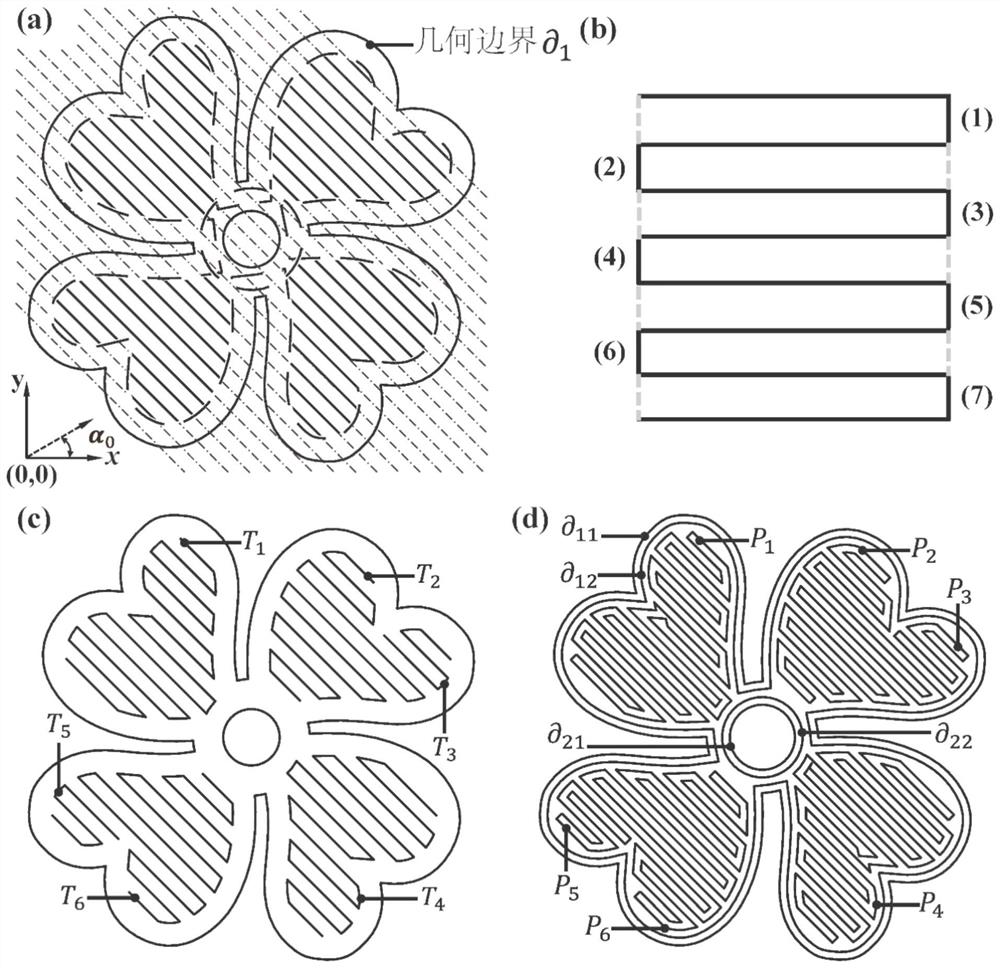

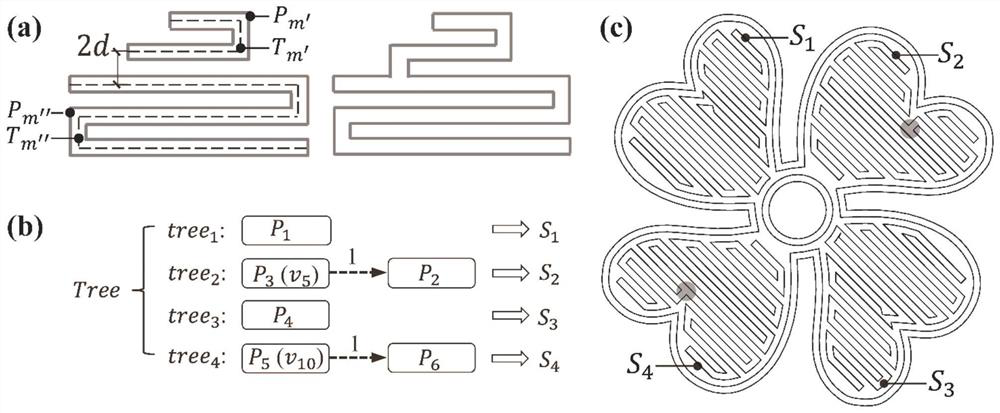

[0028] Step 1. Generate a non-continuous double zigzag filling path and a double-layer contour with a spacing of nozzle diameter d at a given angle in a two-dimensional connected area without islands, such as figure 2 shown;

[0029] (1-1) If figure 2 As shown in (a), in a region larger than the geometric boundary, according to a given angle α 0 Generate parallel scan lines, this example α 0 =-45°, the geometric boundary (here i represents the number of continuous boundaries, such as figure 2 As shown in (a) ) offset inwardly by 3.5d to obtain an offset profil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com