Glazing device for domestic ceramic processing

A technology for ceramic processing and daily use, which is applied in the field of glazing devices for ceramic processing and glazing devices for daily ceramic processing. It can solve the problems of affecting the effect of glazing, increasing production costs, and reducing environmental protection of equipment, so as to improve environmental protection. Sex and utilization efficiency, reduce production cost and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

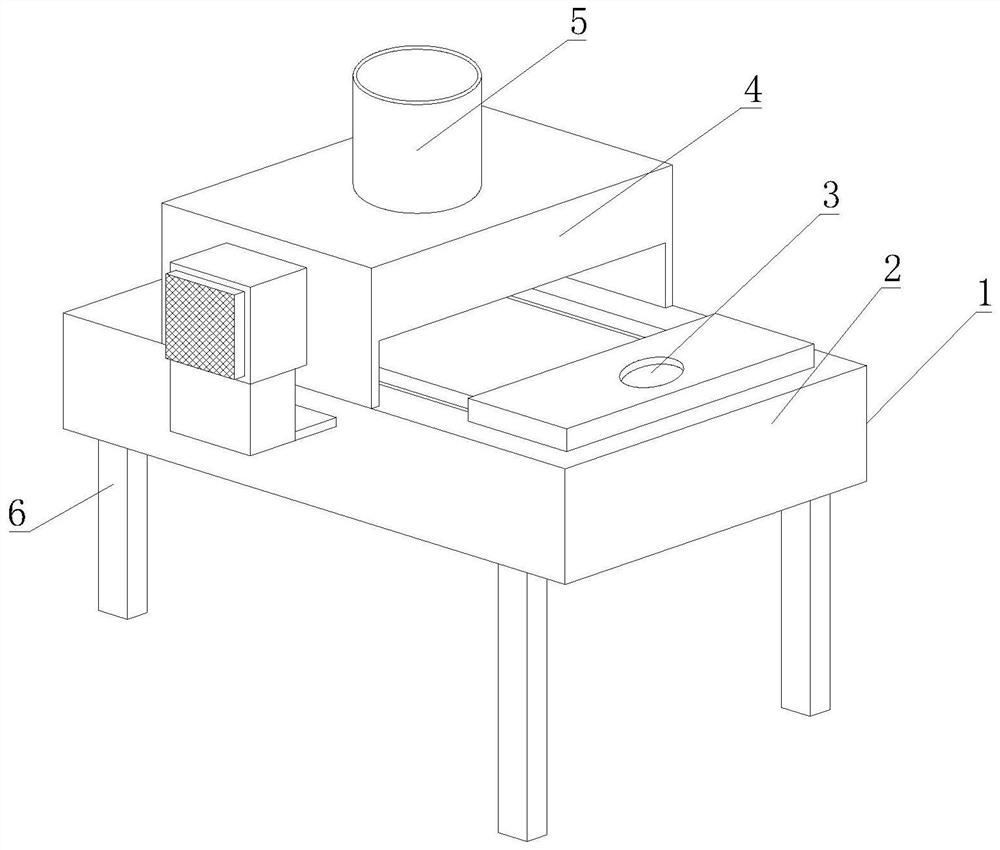

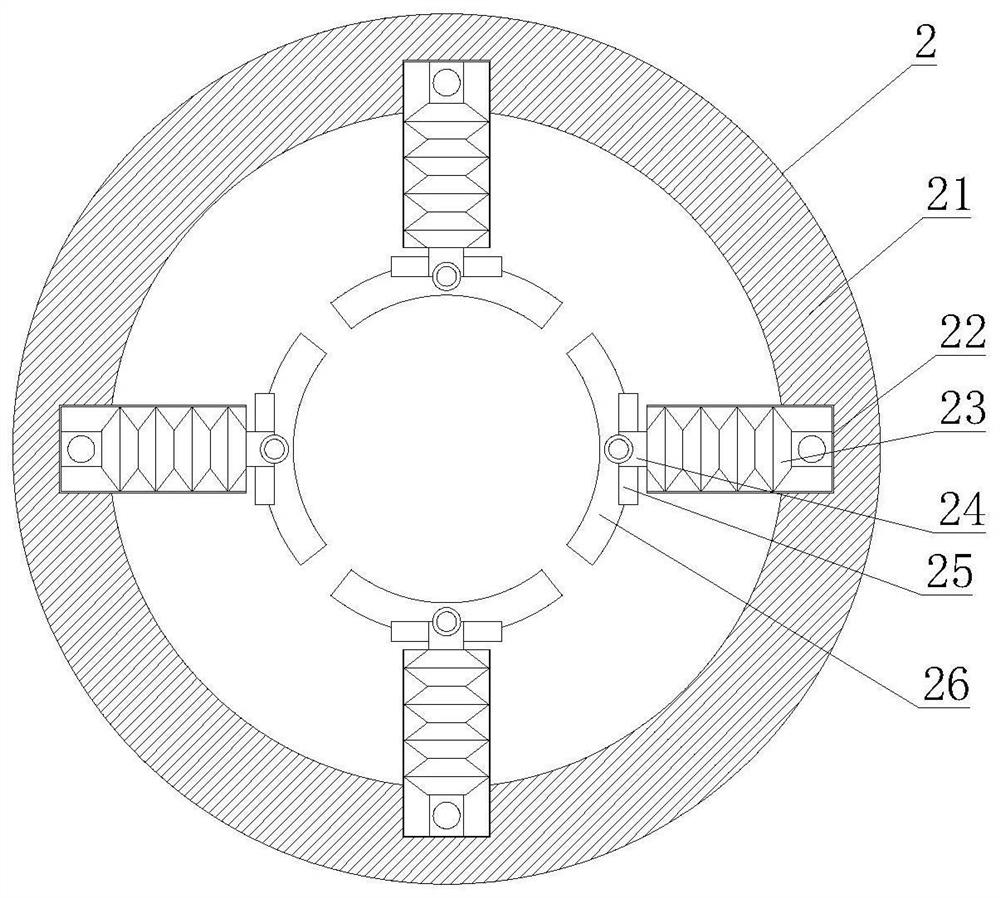

[0051] Such as Figure 1-8 As shown, the present invention provides a glazing device for daily ceramic processing, comprising a glazing device body 1, the glazing device body 1 includes a workbench 2, and the upper surface of the workbench 2 is movably connected with a porcelain bottle holder 3. The top of the workbench 2 is fixedly connected to the glazer 4, the upper surface of the glazer 4 is movably connected to the glaze bottle 5, the four corners of the bottom surface of the workbench 2 are fixedly connected to the shock absorber 6, and the upper surface of the workbench 2 A fixed ring 21 is movably connected, and the top of the fixed ring 21 is movably connected with the bottom surface of the porcelain bottle holder 3. The inner surface of the fixed ring 21 is fixedly connected with a casing 22, and the glazer 4 includes a protective shell 44, and the protective shell 44 The bottom surface is fixedly connected with the upper surface of the workbench 2, the inner cavity ...

Embodiment 2

[0055] Such as Figure 1-8 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, one end of the air outlet pipe 45 extends to the outside of the protective shell 44 and is fixedly connected with the inner and outer surfaces of the protective shell 44, and the air outlet pipe 45 One end of the air outlet pipe 45 is fixedly connected with a purifier 47, the outer surface of the purifier 47 is fixedly connected with the outer surface of the protective shell 44, and the other end of the air outlet pipe 45 is fixedly connected with a fan 46, and the fan 46 is arranged symmetrically about the center line of the protective shell 44. The top of the fan 46 is fixedly connected to the top of the inner cavity of the protective shell 44 .

[0056] In this embodiment, the cooperation of the protective shell 44, the air outlet pipe 45, the fan 46 and the purifier 47 is used to drive the flow of air in the protective shell 44 through the coo...

Embodiment 3

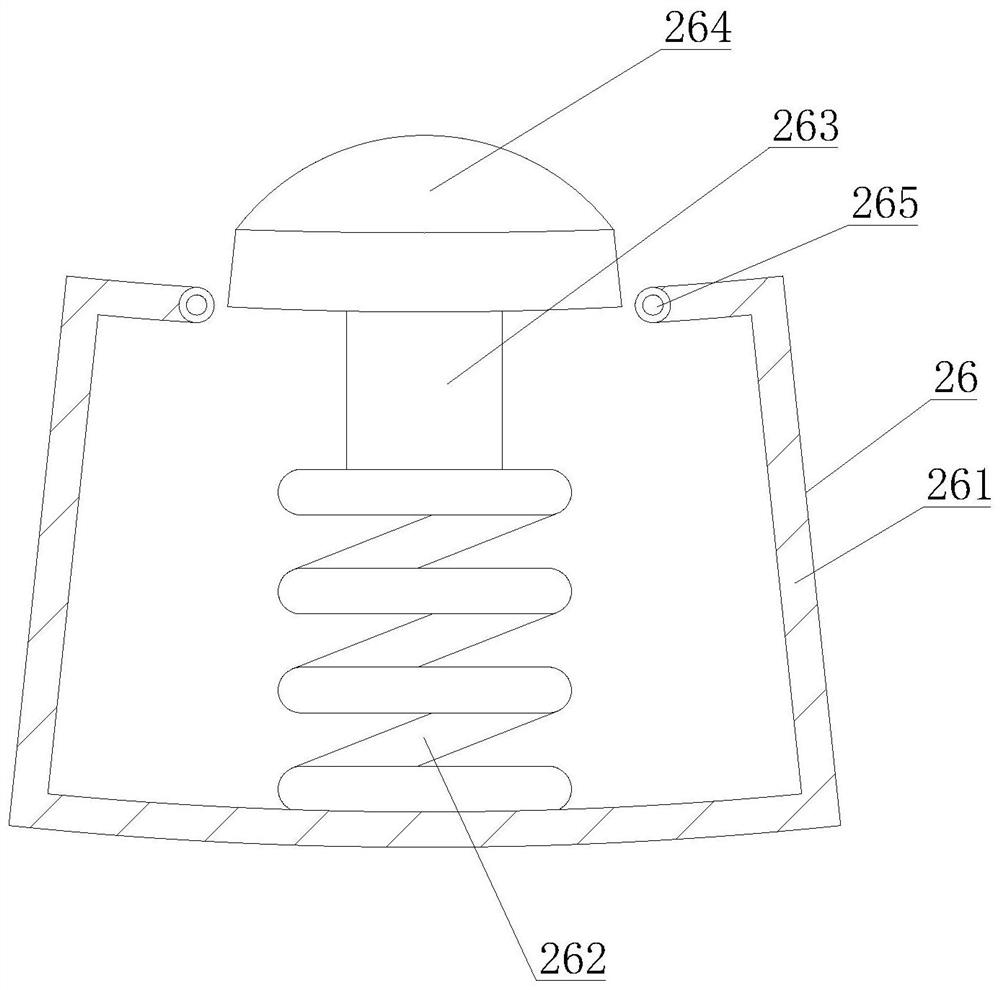

[0058] Such as Figure 1-8 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the top of the inner cavity of the protective shell 44 is fixedly connected with a fixer 48, and the bottom end of the inner cavity side of the protective shell 44 is movably connected with a conveying plate 43, the bottom of the conveying plate 43 is fixedly connected with the spring two 42, and the spring two 42 is arranged symmetrically about the center line of the conveying plate 43, and the bottom of the spring two 42 is fixedly connected with the bottom plate one 41, and the bottom surface of the bottom plate one 41 is connected with the upper surface of the workbench 2. The surface is movably connected, the fixer 48 includes a ferrule 2 481, the outer surface of the ferrule 2 481 is fixedly connected with the inner cavity top of the protective shell 44, and the inner wall of the ferrule 2 481 is fixedly connected with a rotator 482, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com