Wheat impurity removing and drying device for agricultural machinery

A technology of agricultural machinery and drying equipment, which is applied in the direction of drying, drying machines, heating equipment, etc., and can solve problems such as stuck sieve holes, poor cleaning effect of impurities, and the push shaft does not have wheat grain drying, etc. To achieve the effect of preventing particle jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

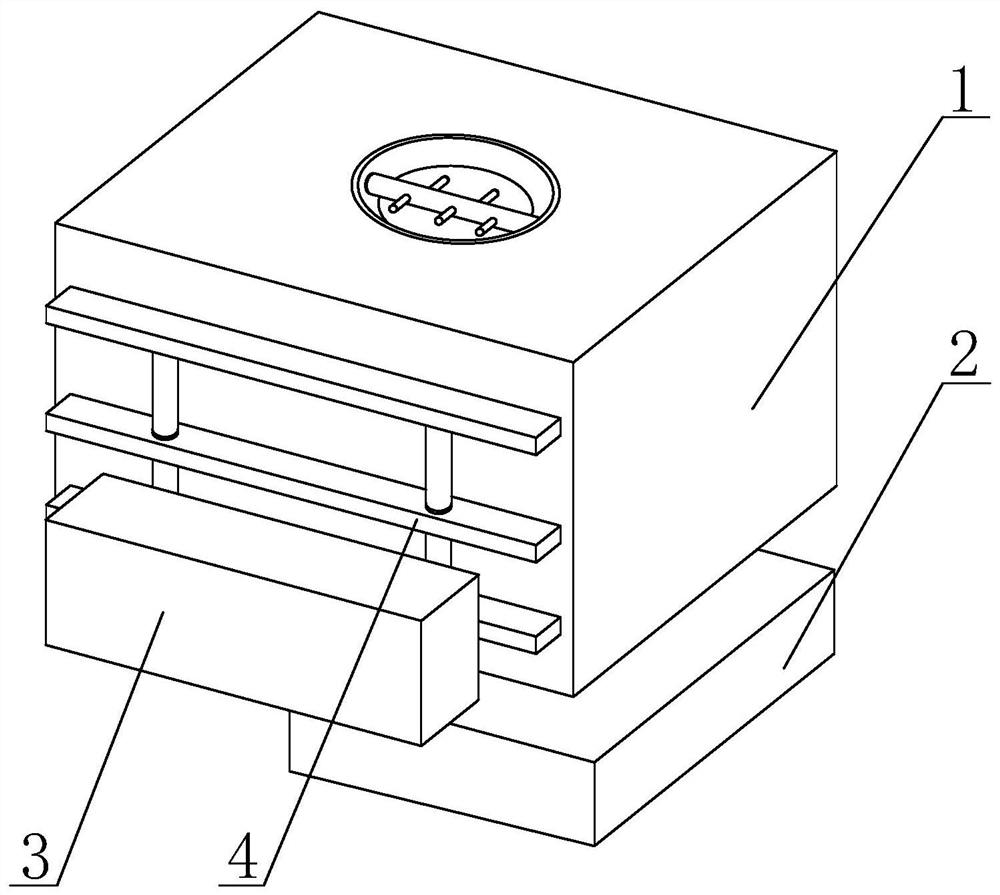

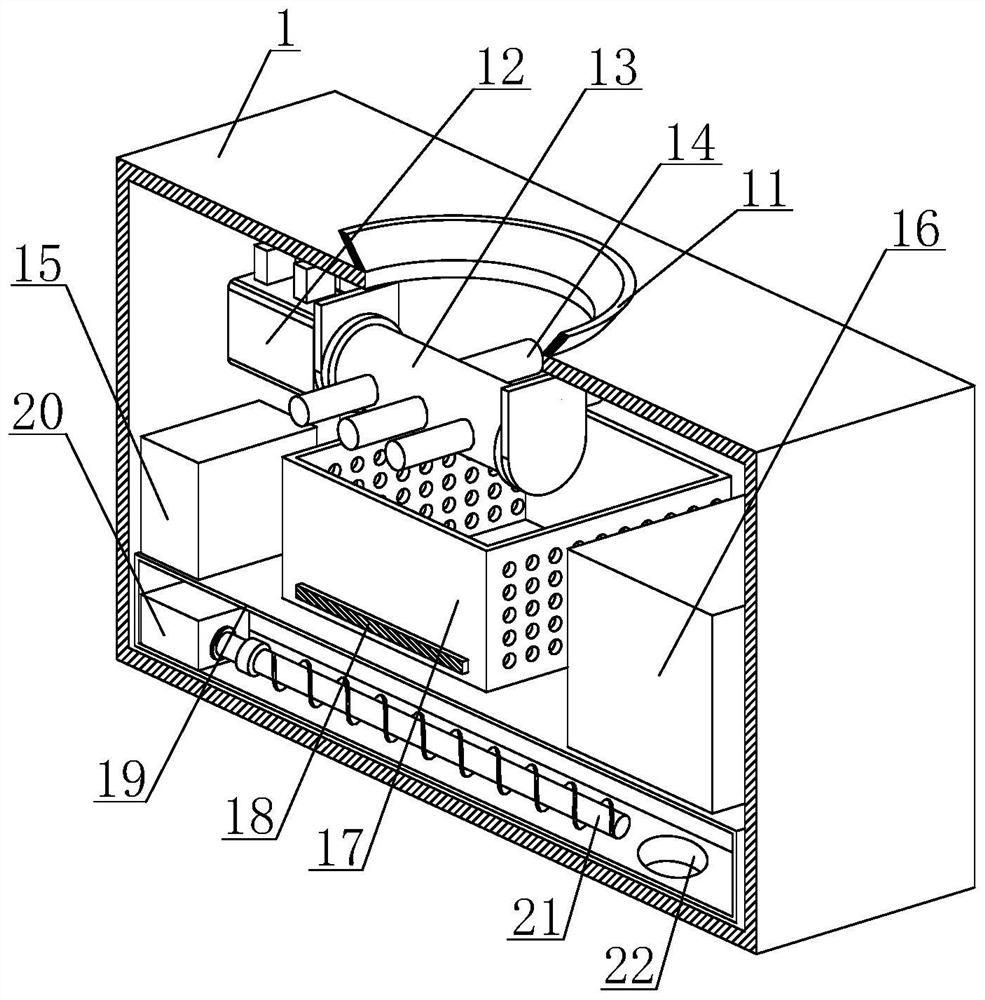

[0029] Such as Figure 1-Figure 7 As shown, the invention provides a kind of wheat impurity removal and drying device for agricultural machinery, comprising a feed box 1, a discharge box 2, a dust collection box 3 and a dust suction pipe 4, the bottom of the feed box 1 and the discharge box The top of 2 is fixedly connected, the front of the feed box 1 is fixedly connected with the back of the dust collection box 3, the top of the dust collection box 3 is connected to the bottom of the suction pipe 4, and the inner wall of the feed box 1 is provided with a first drive motor 12. Waste collection box 15, blowing box 16, filter box 17 and drying box 19, the top of the first drive motor 12 is fixedly connected to the top of the inner wall of the feed box 1, waste collection box 15, blowing box 16 and filter box 17 The bottom of the bottom is fixedly connected with the top of the drying box 19, the inner wall of the filter box 17 is provided with a sieve plate 18, and the top of th...

Embodiment 2

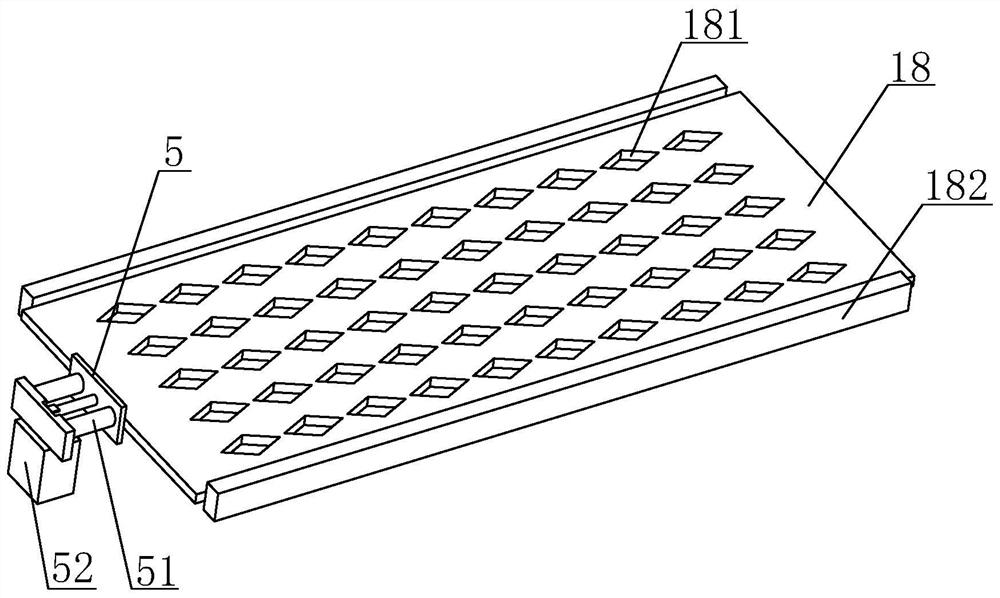

[0033] Such as Figure 3-Figure 5 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the outer wall of the sieve plate 18 is provided with a sieve hole 181, the front and rear sides of the sieve plate 18 are fixedly connected with a sliding plate 182, and the outer wall of the sliding plate 182 is connected to the The left and right sides of the inner wall of the filter box 17 are slidably connected. The inner wall of the filter box 17 needs to be provided with a chute matching the sliding plate 182, so that the sieve plate 18 can slide inside the filter box 17. For some heavier or harder Impurities in the sieve plate 18 can temporarily remain on the sieve plate 18 to prevent it from falling into the inside of the drying box 19 and cause the surface of the pushing shaft 21 to be worn. Elastic piece 1 184 is arranged, and elastic piece 1 184 is positioned at the left and right sides of sieve hole 181 and arranged symmetrically, and the ...

Embodiment 3

[0035] Such as figure 2 , Figure 6 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: preferably, the inner wall of the drying box 19 is provided with a second drive motor 20 and a pusher shaft 21, and the second drive motor 20 The drive end of the drive end is embedded and connected with the left side of the push shaft 21, and the right side of the inner wall of the drying box 19 is provided with a discharge port 22, and the rotation of the drive end of the second drive motor 20 drives the push shaft 21, thereby filtering The wheat that case 17 falls is pushed in the discharge port 22, and the bottom of the second drive motor 20 is screwed with the inner wall bottom of drying box 19, and the outer wall of pushing shaft 21 is sleeved with axle sleeve 23, and the outer wall of axle sleeve 23 The outer wall is rotatably connected with a baffle plate 24, and the baffle plate 34 provided is in order to prevent some part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com