Sulfur indium zinc-MXene quantum dot composite photocatalyst as well as preparation method and application thereof

A technology of composite light and catalyst, applied in the field of photocatalysis, can solve the problems of low photogenerated carrier recombination rate, low photocatalytic hydrogen production activity, limited visible light utilization rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

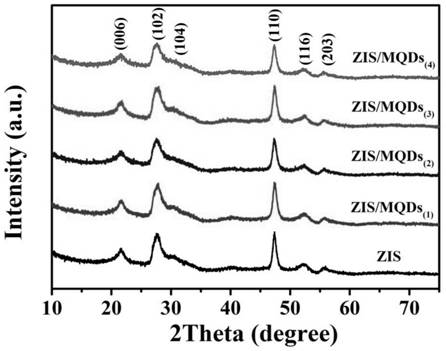

[0034] 1. This step provides ZnIn 2 S 4 (ie ZIS) photocatalyst preparation, its preparation method comprises the following steps.

[0035] 0.136g (1mmol) ZnCl 2 , 0.586g (2mmol) InCl 3 4H 2 O. Dissolve 0.46g (6mmol) thioacetamide in 80mL deionized water and stir for 30min to obtain a suspension. The suspension obtained above was transferred into a 100mL reaction kettle with a polytetrafluoroethylene substrate, and placed in an oven at 80°C for 12h. Naturally cool to room temperature after the reaction, centrifuge to obtain a yellow powder sample, wash the yellow powder sample several times with deionized water and absolute ethanol, and dry it in a common oven at 60°C for 5 hours to obtain pure ZIS powder.

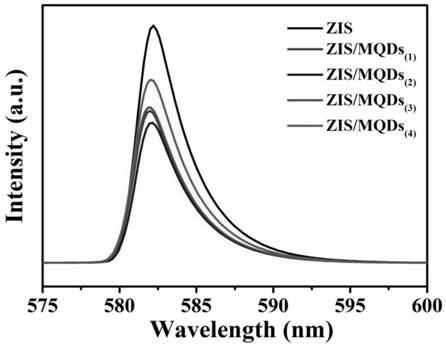

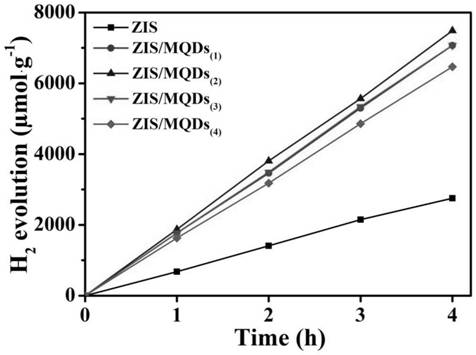

[0036] 2. This step provides ZIS / MQDs (1) The preparation of photocatalyst, its preparation method comprises the following steps.

[0037] Stir 2.0 g of LiF and 40 mL of 9M HCl in a Teflon beaker for 30 min. Add 2.0g of MAX-Ti 3 AlC 2 Slowly added to a polytetrafl...

Embodiment 2

[0040] This embodiment provides ZIS / MQDs (2) The preparation of photocatalyst, its preparation method comprises the following steps.

[0041] Stir 2.0 g of LiF and 40 mL of 9M HCl in a Teflon beaker for 30 min. Add 2.0g of MAX-Ti 3 AlC 2 Slowly added to a polytetrafluoroethylene beaker, and set the temperature to 35°C, and continued to stir for 24h. Then centrifuge at 3500rpm for 10min, and wash with deionized water several times until the pH value of the supernatant poured out after centrifugation is 5 to obtain solid Ti 3 C 2 (MXene) powder. At 1.0g Ti 3 C 2 Add 40 mL of absolute ethanol to the solution, sonicate for 1 h, and then centrifuge at 10,000 rpm for 10 min to collect the suspended Ti 3 C 2 Nanosheets. Add 20 mL of deionized water to the unexfoliated particles, place in a cell crushing device at 80% power for 1 h, and then centrifuge at 3500 rpm for 3 min to collect the suspended Ti 3 C 2 Nanosheets. Repeat the above steps several times to get more Ti ...

Embodiment 3

[0044] This embodiment provides ZIS / MQDs (3) The preparation of photocatalyst, its preparation method comprises the following steps.

[0045] Stir 2.0 g of LiF and 40 mL of 9M HCl in a Teflon beaker for 30 min. Add 2.0g of MAX-Ti 3 AlC 2 Slowly added to a polytetrafluoroethylene beaker, and set the temperature to 35°C, and continued to stir for 24h. Then centrifuge at 3500rpm for 10min, and wash with deionized water several times until the pH value of the supernatant poured out after centrifugation is 5 to obtain solid Ti 3 C 2 (MXene) powder. At 1.0g Ti 3 C 2 Add 40 mL of absolute ethanol to the solution, sonicate for 1 h, and then centrifuge at 10,000 rpm for 10 min to collect the suspended Ti 3 C 2 Nanosheets. Add 20 mL of deionized water to the unexfoliated particles, place in a cell crushing device at 80% power for 1 h, and then centrifuge at 3500 rpm for 3 min to collect the suspended Ti 3 C 2 Nanosheets. Repeat the above steps several times to get more Ti ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com