Memory non-ironing foldable clothing composite material, manufacturing method and application thereof

A composite material and clothing technology, applied in clothing, clothing, clothing and other directions, can solve the problems of clothing and clothing that are not easy to fold, limited scene application conditions, and inconvenient to wear and use, and achieve rich material and cultural life, low logistics and transportation costs, and appearance. invariant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

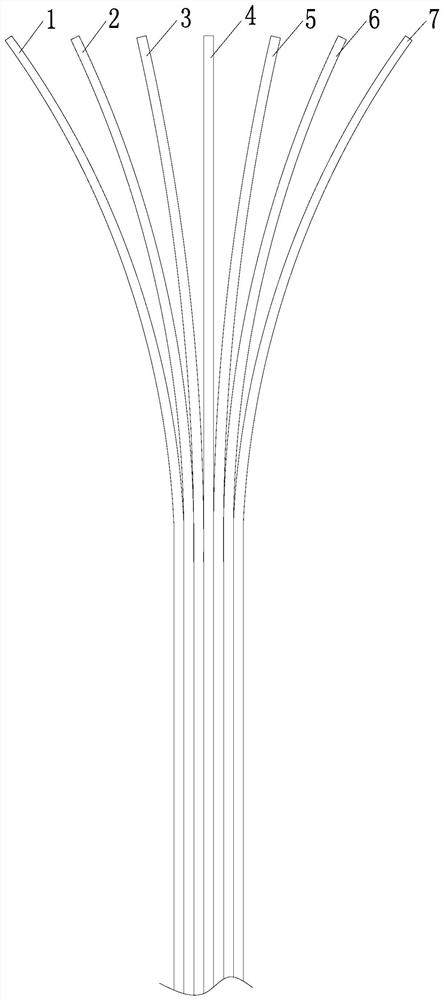

[0037] Embodiment one: if figure 1As shown, the memory non-ironing foldable clothing and apparel composite material of the present invention includes seven layers of materials, wherein the fourth layer 4 in the middle position is a silica gel layer, the third layer 3 and the fifth layer adjacent to the middle layer 5 are all set as an adhesion layer, the second layer 2 outside the third layer 3 is set as a base material composite layer, the sixth layer 6 outside the fifth layer 5 is also set as a base material composite layer, and the first layer outside the second layer 2 is set as a base material composite layer. Layer 1 is set as the fabric layer, and the seventh layer 7 on the outside of the sixth layer 6 is set as the lining layer; the clothing and apparel composite material with memory, non-ironing and foldable functions composed of seven layers of materials can be formed according to the clothing Apparel design scheme, through conventional cutting and sewing process, ca...

Embodiment 2

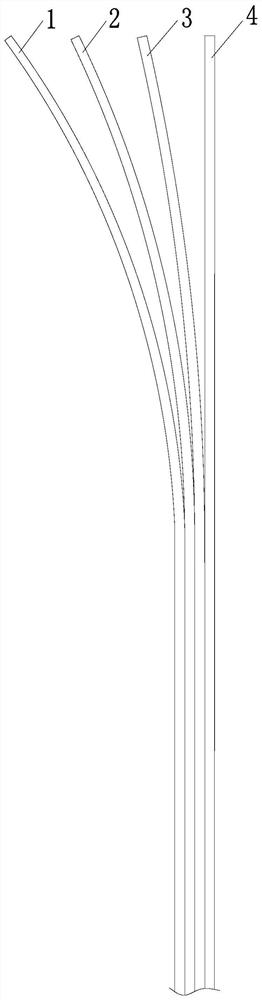

[0053] Embodiment two: if figure 2 As shown, the memory non-ironing foldable clothing and apparel composite material of the present invention, on the basis of the technical solution of Embodiment 1, omits the inner layer structure and only includes four layers of materials, of which the fourth layer 4 at the bottom position adopts a silica gel layer , the third layer 3 above the silica gel layer adopts an adhesive layer, the second layer 2 above the adhesive layer adopts a substrate composite layer, and the first layer 1 above the substrate composite layer adopts a fabric layer; the memory non-ironing of embodiment two is foldable Clothing and apparel composite materials have no lining. According to the clothing and apparel design scheme, the corresponding lining structure can be selected, or combined with other apparel and apparel materials to form a multi-layer structure, and then sewn by conventional cutting, sewing or gluing processes. Made into finished clothing and acce...

Embodiment 3

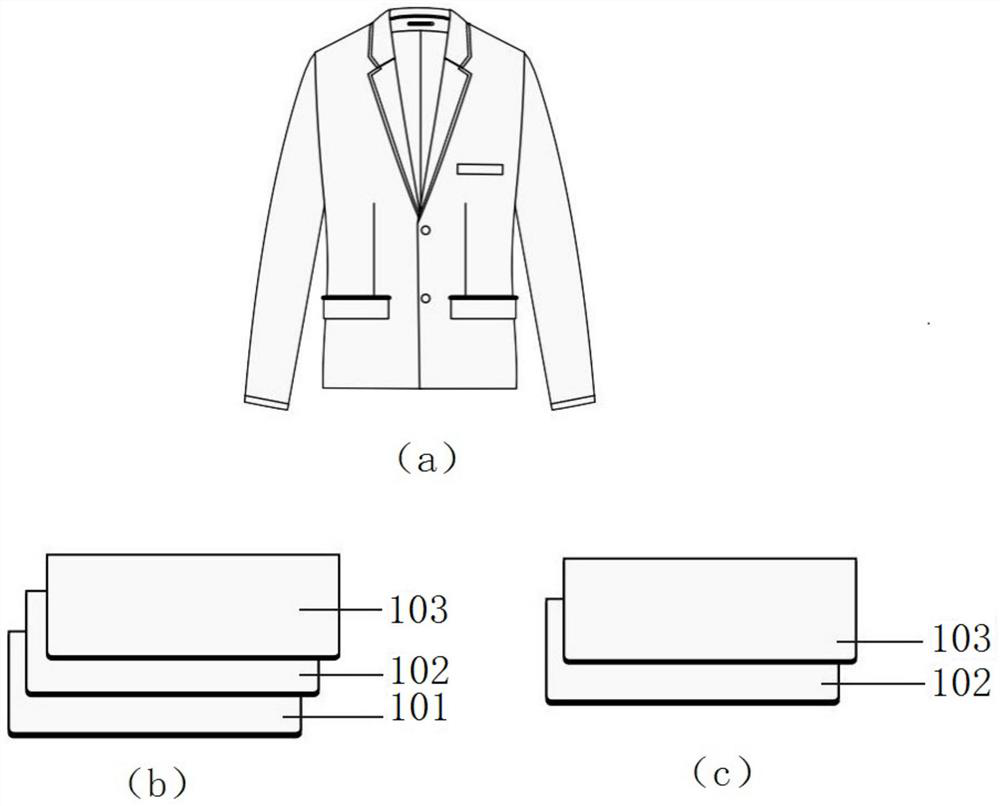

[0061] Embodiment three: as image 3 As shown, the present invention combines the application of the memory non-ironing foldable clothing and apparel composite materials of Embodiment 1 and Embodiment 2 in outerwear such as suits, jackets or protective clothing (hereinafter referred to as outerwear). Cutting, compounding, sewing, shaping or gluing to form the finished coat, image 3 (a); or according to the specific application design scheme and cost control, another layer of lining 103 is set inside the memory non-ironing foldable clothing and apparel composite material 102, and another layer of lining is set outside the memory non-ironing foldable clothing and apparel composite material layer fabric 101, image 3 (b) The finished jacket with a three-layer material structure is sewn by conventional cutting, compounding, sewing, shaping or gluing processes, and the memory non-ironing foldable clothing and apparel composite material can also be directly placed at the end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com