Production of non-woven cotton cloth with coating function finishing

An all-cotton non-woven fabric and production method technology, which are applied in the treatment of textile materials, local treatment of textile materials, textiles and papermaking, etc., can solve the problems of large loss, reduced wearing comfort, and difficulty in cleaning, and reduce pollution. and waste, increase the protection function, reduce the effect of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

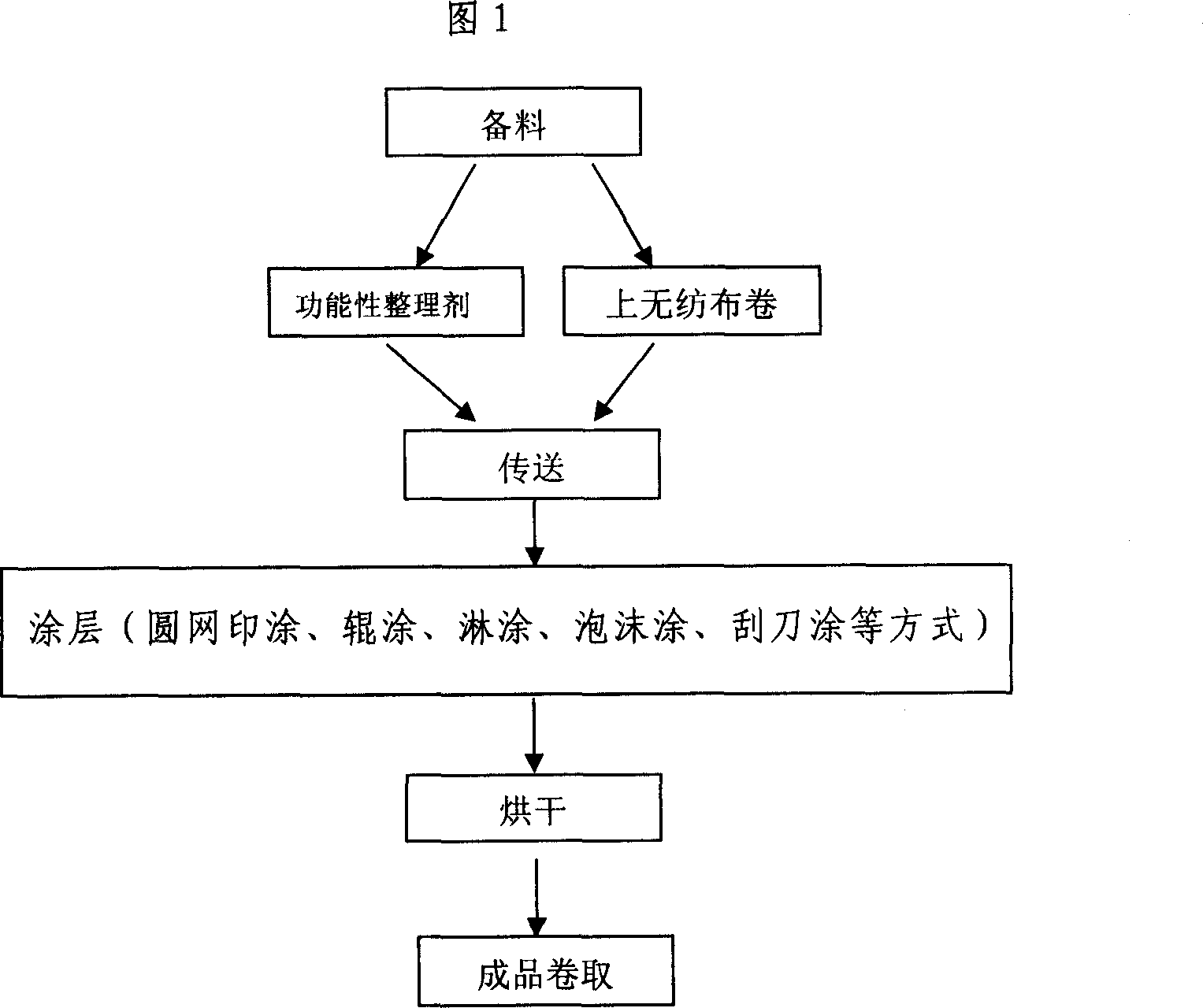

[0017] A. Material preparation (that is, the preparation of cotton non-woven rolls, the mixing of finishing agents)

[0018] B. Conveying (that is, all cotton non-woven fabric rolls and finishing agents are sent to the production station)

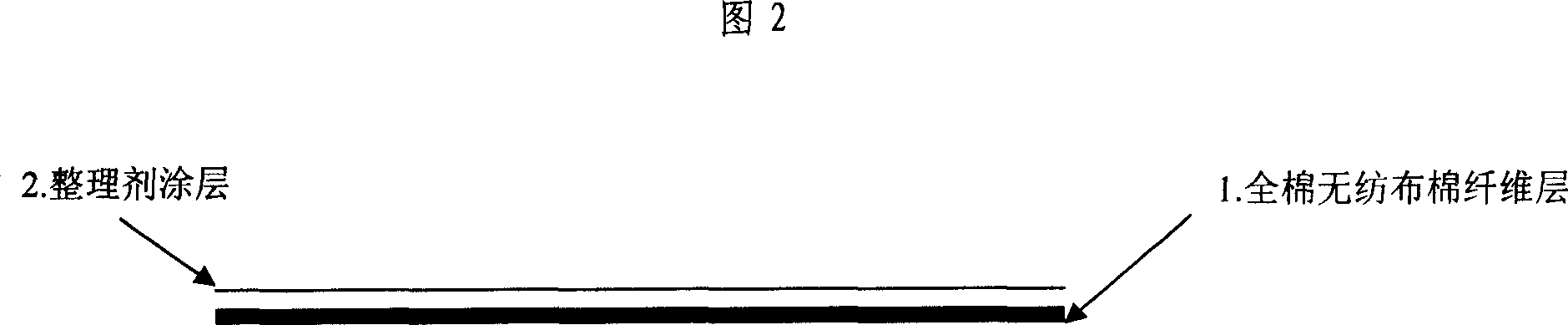

[0019] C. coating (by the coating method described in claim 2, the finishing agent is coated on the surface "illustration 1" of the cloth roll such as "illustration 2")

[0020] D. Drying (using radiation, hot air, drying cylinder, etc. to dry, to promote the cross-linking and curing of finishing agents and fibers)

[0021] E. coiling

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com