Fried bean curd air pressure equipment

An oiled tofu and air pressure technology, which is applied in the field of oiled tofu air pressure equipment, can solve the problems of uneven end faces of tofu blocks, inconsistent size of tofu blocks, affecting the appearance of oiled tofu, etc., and achieves the effects of rapid extrusion molding and accelerated outflow speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Please refer to Figure 1-Figure 5 , the specific embodiments of the present invention are as follows:

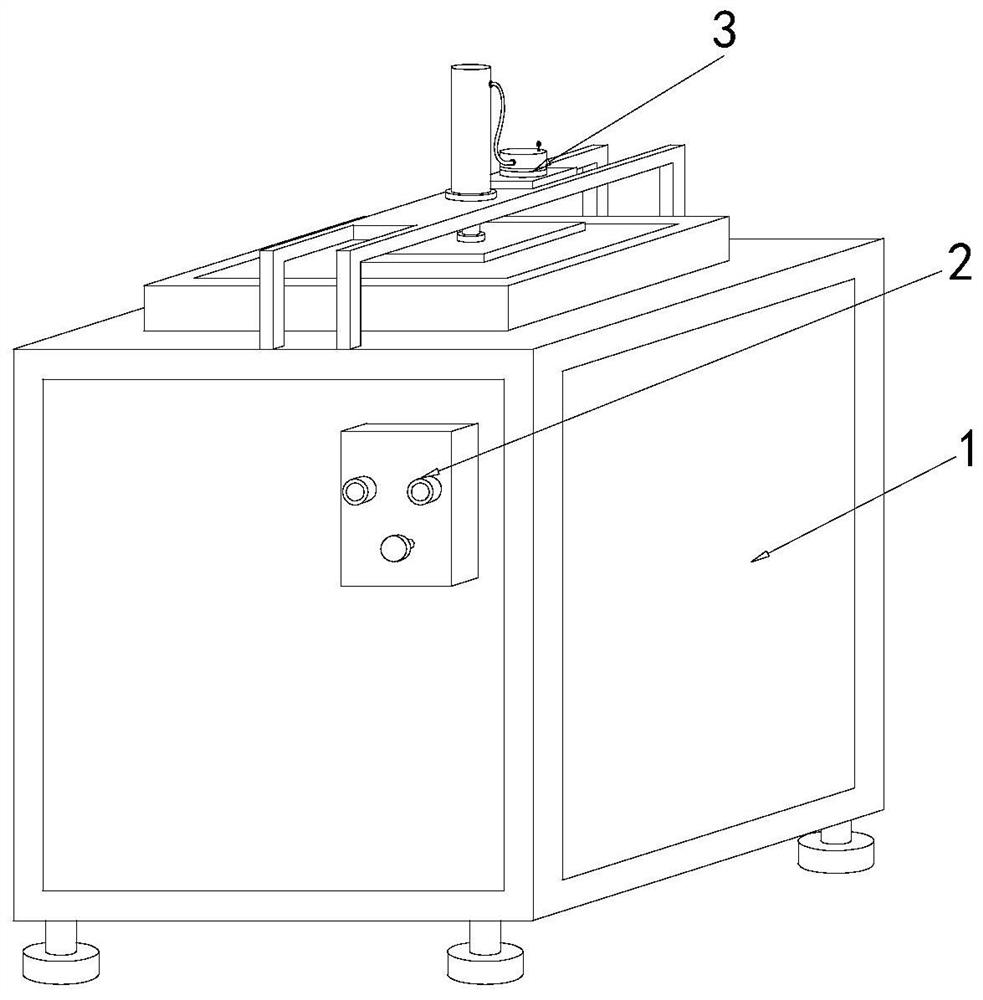

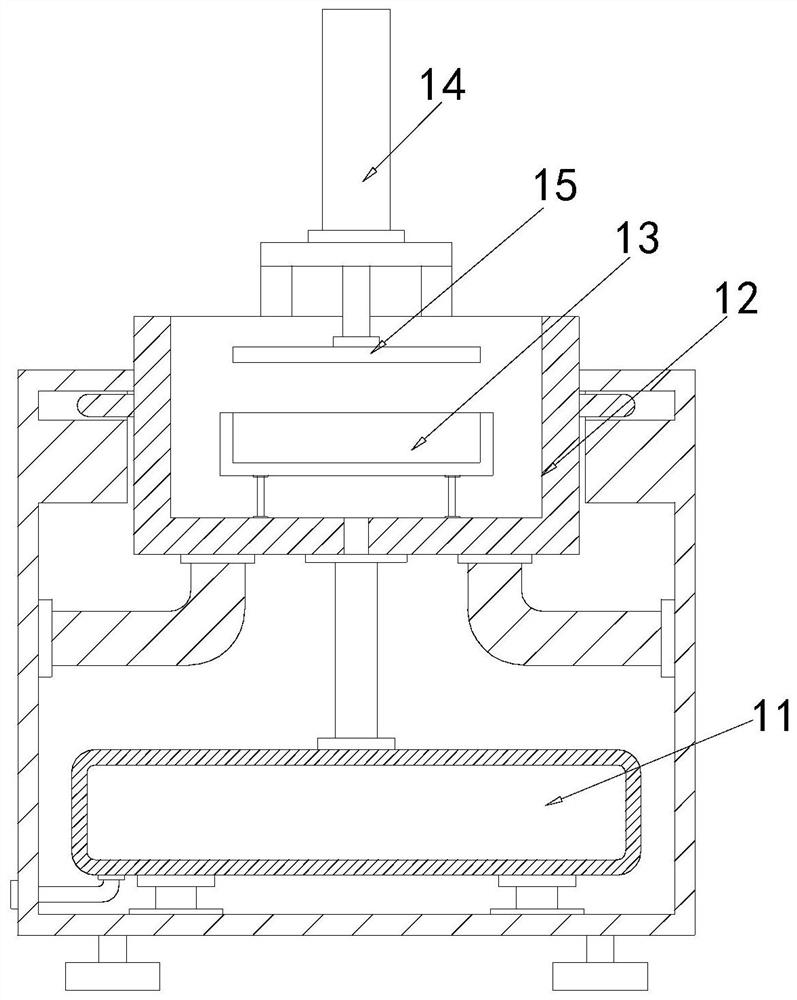

[0027] Its structure includes a main body 1, a control panel 2, and an air pump 3. The front end of the main body 1 is equipped with a control panel 2. The air pump 3 is arranged on the top of the main body 1. The main body 1 includes a collection box 11 and a lower pressure frame 12. , a charging box 13, a telescopic arm 14, and a pressing device 15, the collecting box 11 is arranged at the inner bottom of the main body 1, the lower pressing frame 12 is located at the inner top of the main body 1, and the charging box 13 is embedded Fixed in the middle of the lower pressing frame 12, the telescopic arm 14 is located directly above the charging box 13, and the lower pressing device 15 is connected to the bottom of the telescopic arm 14.

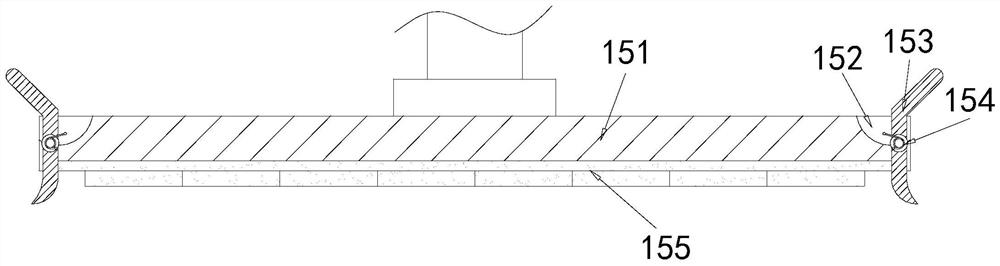

[0028] The pressing device 15 includes a lower pressing plate 151, a rotating groove 152, a sealing block 153, a rewin...

Embodiment 2

[0032] Example 2: Please refer to Figure 6-Figure 8 , the specific embodiments of the present invention are as follows:

[0033]The decompression device 155 includes a water baffle b1, a water guide b2, a water pressure hole b3, a cotton cloth b4, and a drainage hole b5. Between the pressure plate 151 and the water baffle b1, the water pressure holes b3 are provided with more than ten, and are arranged horizontally at the bottom of the water baffle b1, and the cotton cloth b4 is embedded in the bottom of the water baffle b1, so that There are three drainage holes b5, which are respectively located at the side ends of the water baffle b1. The angle between the drainage holes b5 and the horizontal plane is 45 degrees, which is conducive to draining the water accumulated in the water guide groove b2 through the drainage holes b5. Drain out.

[0034] The pressure water hole b3 includes a water filter hole b31, an anti-reflux block b32, a raised block b33, and a flow hole b34. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com