40-pin signal transmission cable with distance of 0.8 mm and manufacturing method thereof

A technology of transmission cable and manufacturing method, which is applied to circuits, electrical components, coupling devices, etc., can solve the problems of lack of competitiveness, high process defect rate, large cable size, etc., to achieve a simple and easy-to-operate assembly structure, and reduce process defects. rate, the effect of reducing the overall size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]The technical solutions in the embodiments of the present invention will be apparent from the drawings in the embodiment of the present invention.

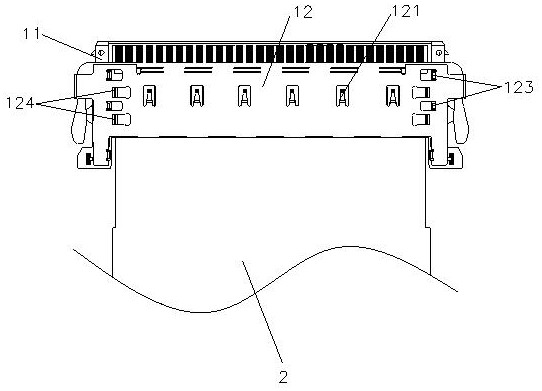

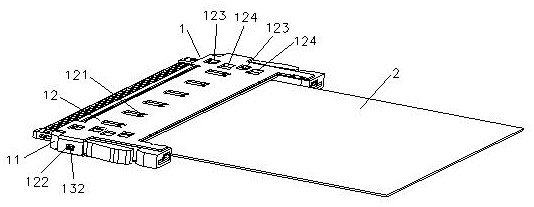

[0028]SeeFigure 1-4As shown, the embodiment of the present invention discloses a 0.8 mm pitch 40pin signal transmission cable, including connector 1 and FFC (flexible flat cable) cable 2, and the conductive end of the FFC cable 2 is inserted into the connector 1, FFC The spacing between the wires 2 is 0.8 mm, and the number of wires of the FFC cable 2 is 40.

[0029]The connector 1 includes an insulating housing 11, the upper metal sheet 12, and the lower metal sheet 13, and the FFC cable 2 is inserted into the insulating housing 11, and the upper metal sheet 12 and the lower metal sheet 13 are located in the insulating housing 11, respectively. Upon and down, the upper metal sheet 12 is buckled with the lower metal sheet 13 and the FFC cable 2 is oppressed.

[0030]A plurality of down-inclined upper metal stroke arms 121 are provided on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com