Cutterhead for shield tunneling of moderately-weathered argillaceous siltstone

A technology of siltstone and cutter head, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of cutter head wear, slow tunneling of shield machine, reducing the working efficiency of shield machine and the service life of cutter head, etc. Achieve the effect of strengthening the anti-wear ability and improving the rock-breaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

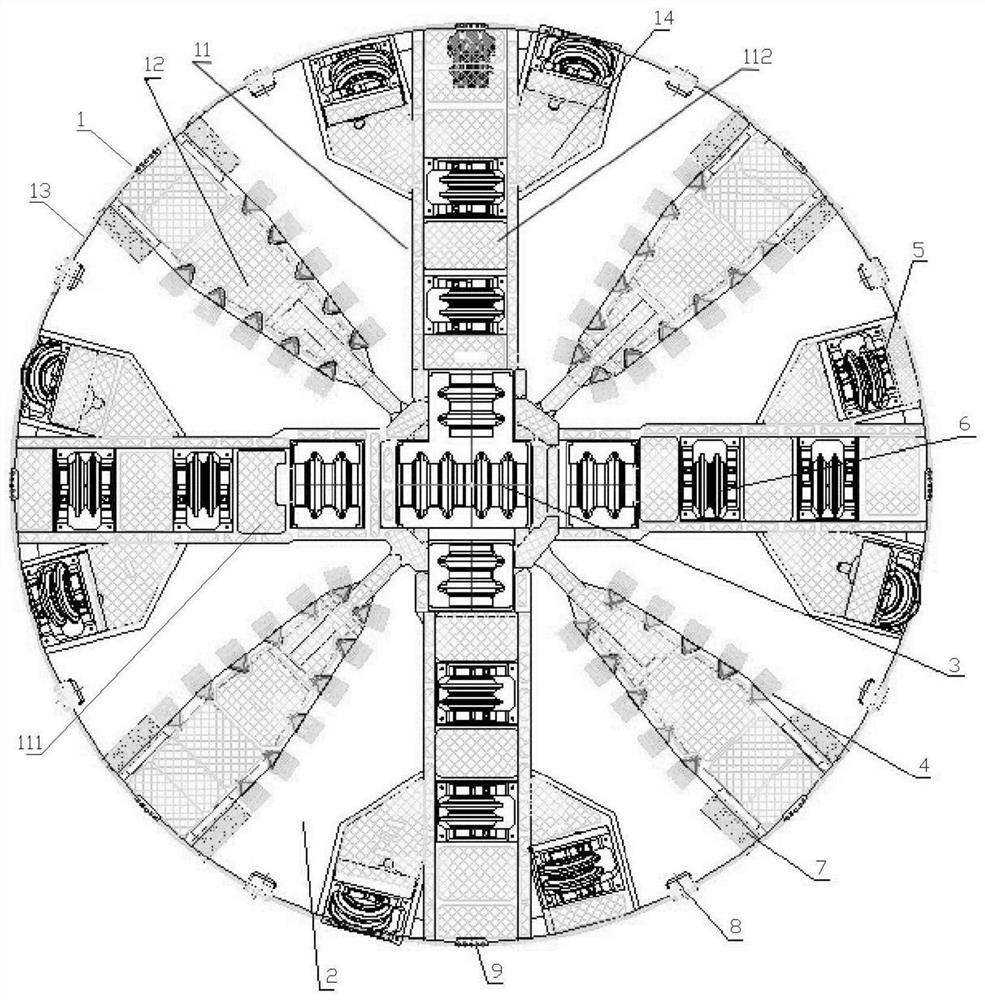

[0041] Such as figure 1 As shown, a cutterhead for shield tunneling in moderately weathered argillaceous siltstone, including:

[0042] The cutter head body 1 is installed on the driving device of the shield machine, and the cutter head body 1 is disc-shaped;

[0043] The cutterhead opening 2 is arranged on the cutterhead body 1 and communicates with the soil chamber of the shield machine;

[0044] The central heavy-duty flat-tooth double hob 3 is arranged on the cutter head body 1;

[0045] The cutter 4 is arranged on the cutter head body 1;

[0046] Edge heavy-duty flat-tooth double-edged hob 5 is arranged on the edge of the cutter head body 1;

[0047] The front heavy-duty flat-tooth double-edged hob 6 is arranged on the cutter head body 1;

[0048] An edge scraper 7 is arranged on the edge of the cutter head body 1;

[0049] The gage knife 8 is arranged on the edge of the cutter head body 1;

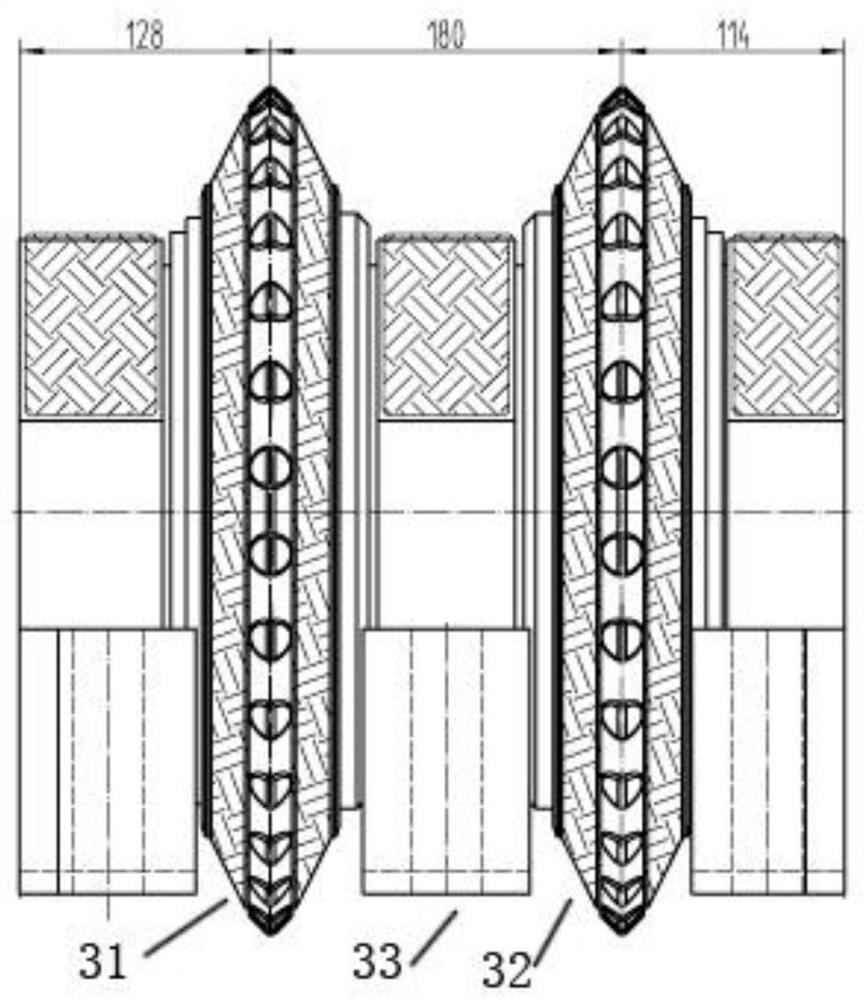

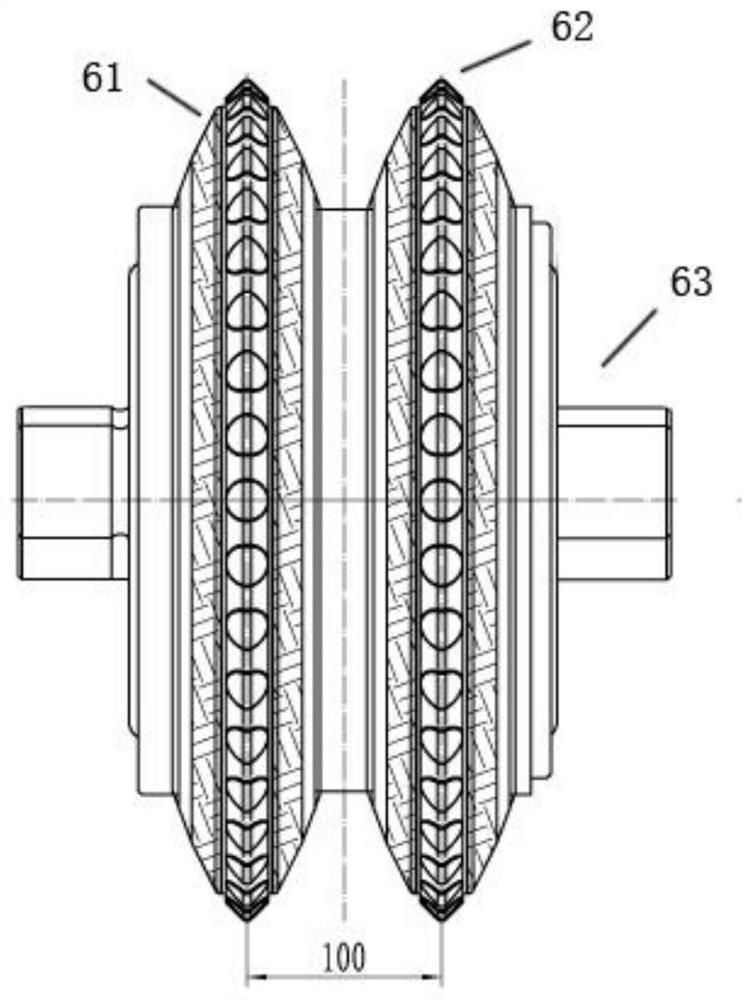

[0050] The cutting edge of the front heavy-duty flat tooth double-edged ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com