Rock wool belt heat preservation composite board with turnover mechanism

A thermal insulation composite board and flipping mechanism technology, which is applied in thermal insulation, building thermal insulation materials, building components, etc., can solve the problems that composite boards are prone to cracking and cannot achieve waterproof and thermal insulation effects, and achieve ingenious design, simple structure, and guaranteed thermal insulation effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

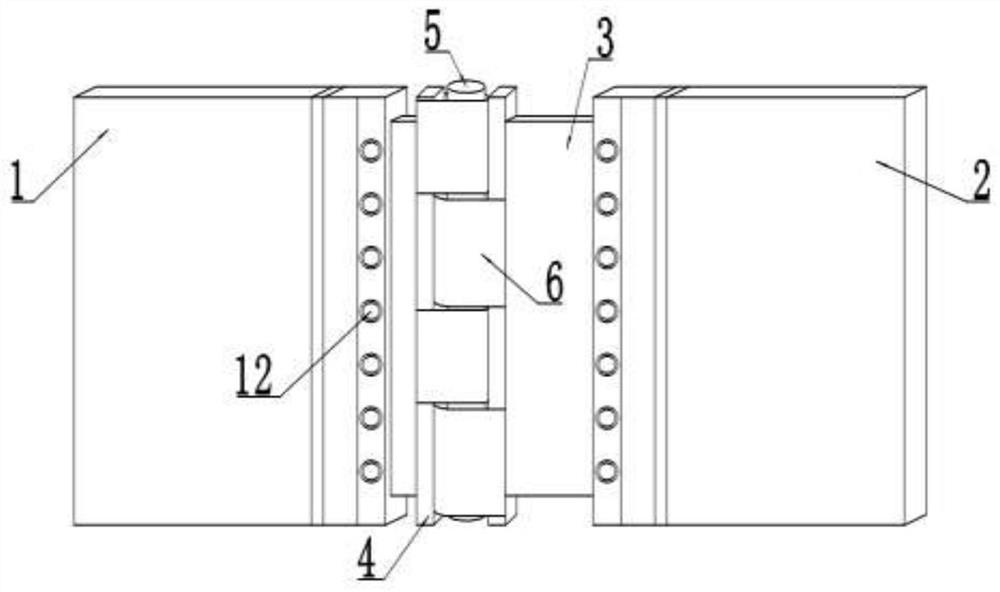

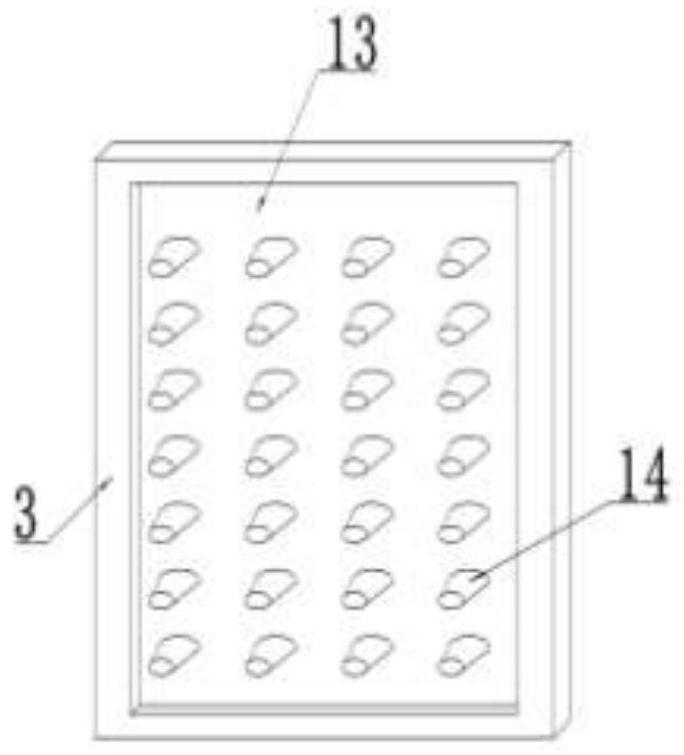

[0027] Specific implementation method: when installing the composite board to the yin and yang corners, adjust and fix the first composite board body 1 in a good position, pull the third composite board body 3 to slide outward along the opening to the yin and yang corners, and place the second composite board body 2 along the The round rod 5 rotates until the second composite panel body 2 contacts the wall, and the second composite panel body 2 is installed and fixed.

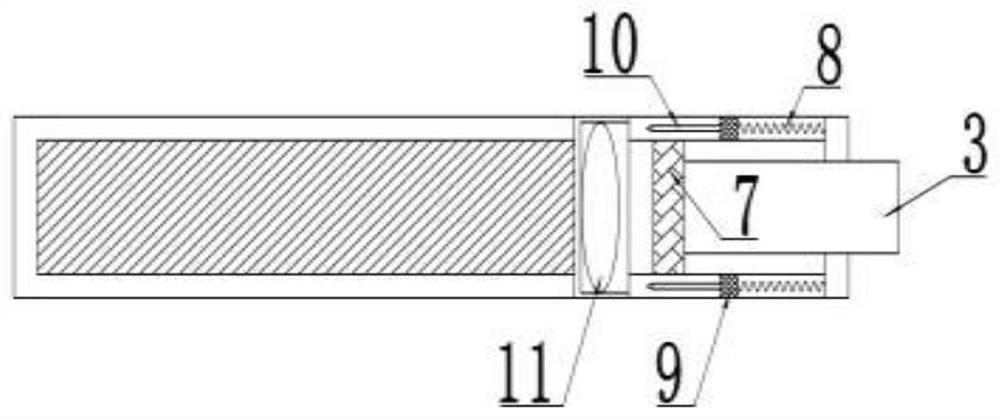

[0028] During the sliding process of the third composite plate body 3 along the opening, the first sealing plate 7 moves in the cavity, generating airflow through the air holes and entering the front and rear inner walls of the cavity, and the second sealing plate 9 drives the nail 10 to the direction of the pouch 11 movement, and the pouch 11 is pierced, and the mortar in the pouch 11 flows out and is filled into the cavity, thereby ensuring the thermal insulation effect of the first composite board body 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com