Rotary sorting and conveying device for high-temperature gas cooled reactor spherical fuel elements

A spherical fuel element, high temperature gas-cooled reactor technology, used in rotary conveyors, conveyors, transportation and packaging, etc., can solve the problem of inability to achieve multi-category distinction, inability to achieve multi-category distinction, and inability to achieve refined management. and other problems, to achieve the effect of strong practicability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail below in conjunction with accompanying drawing:

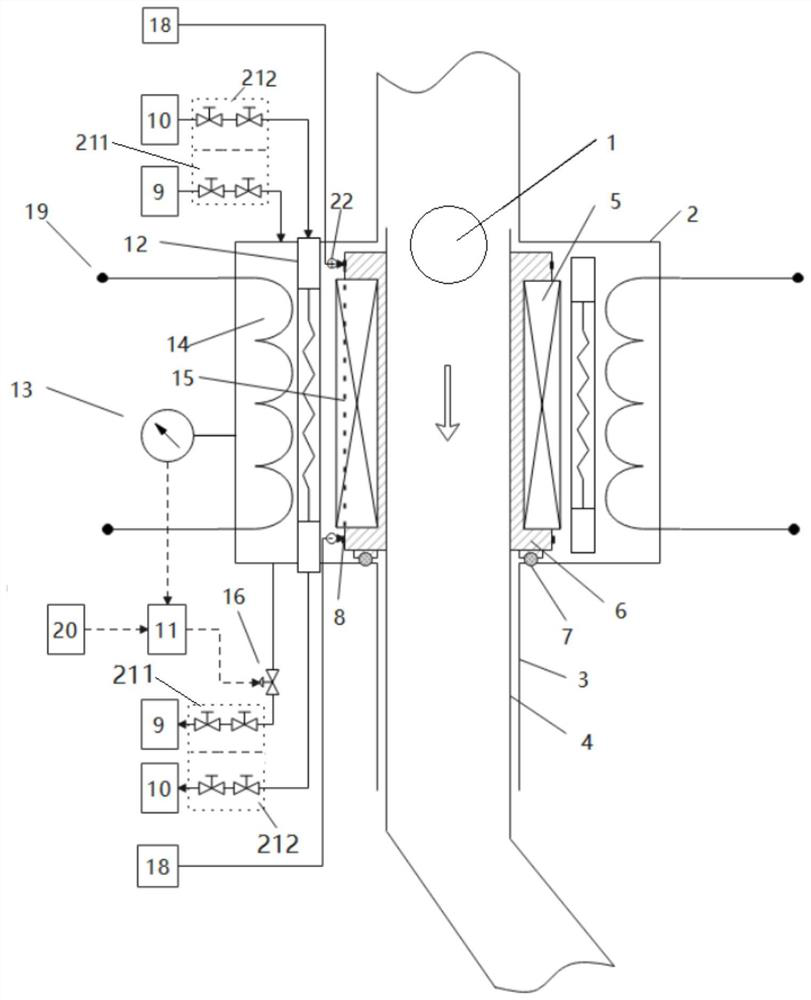

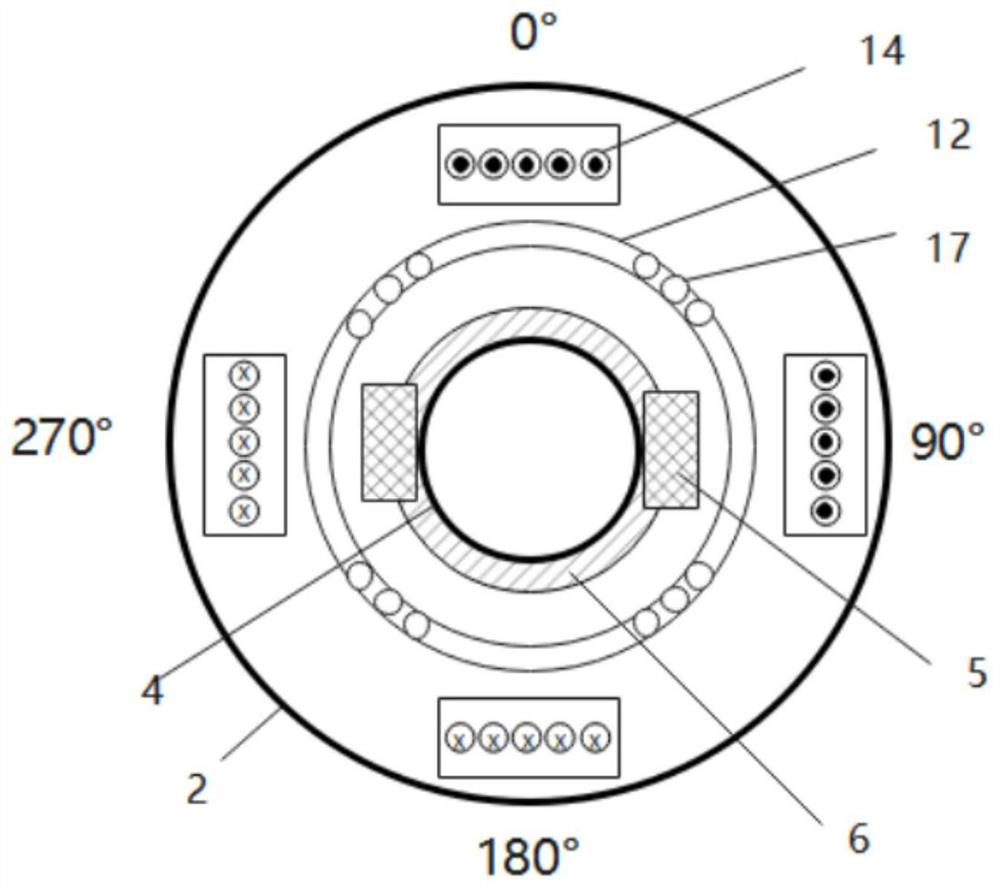

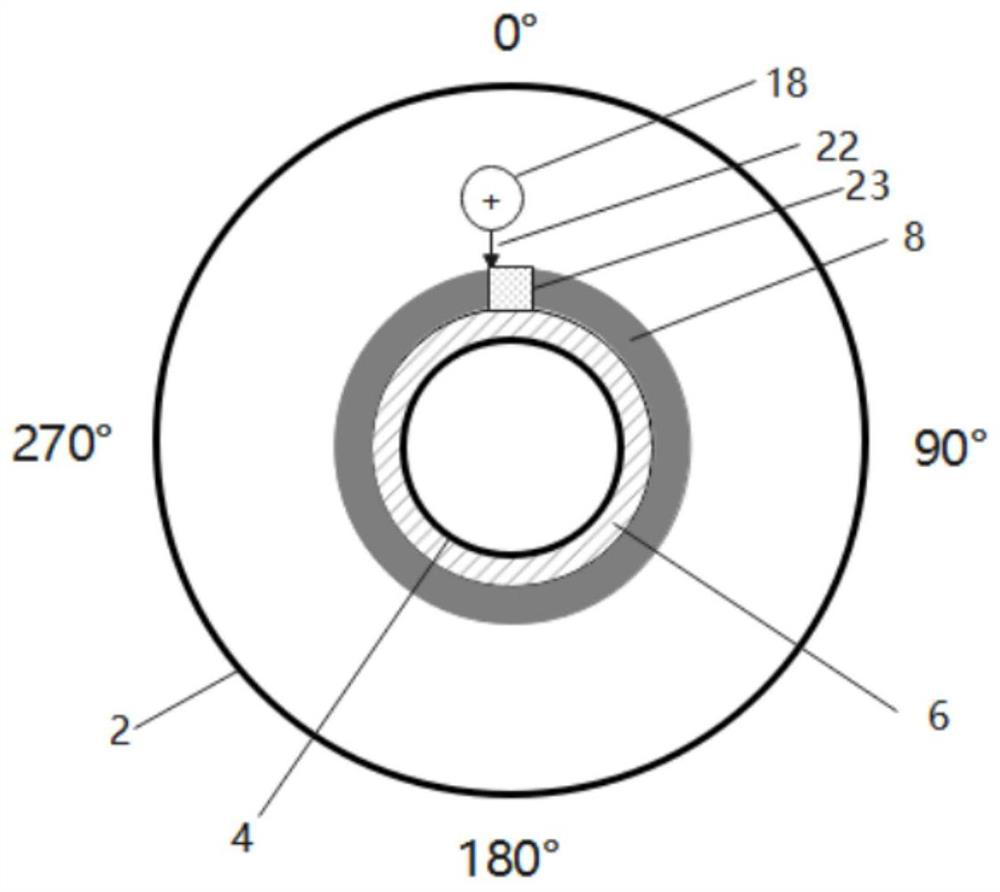

[0021] refer to Figure 1 to Figure 3 The rotary sorting and conveying device for high temperature gas-cooled reactor spherical fuel elements according to the present invention includes a rotary sorting and conveying device body 2, the rotary sorting and conveying device body 2 includes a conveying device shell 3 and a rotating device inner tube 4, One end of the inner tube 4 of the rotating device is bent, and the other end of the inner tube 4 of the rotating device is inserted into the shell 3 of the conveying device. A cavity is formed between the inner tube 4 of the rotating device and the shell 3 of the conveying device. An installation base 6 is provided on which the permanent magnet 5 is mounted. Several sets of adjustable electromagnetic coils 14 are arranged on the inner wall of the conveying device housing 3 . Each set of adjustable electromagnetic coils 14 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com