Wet-type high-voltage electrostatic equipment

A high-voltage electrostatic equipment technology, applied in the field of wet high-voltage electrostatic equipment, can solve the problems of cost increase, waste of water resources, and reduced dust removal effect, and achieve the effect of improving the use effect, improving the adsorption capacity, and improving the dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

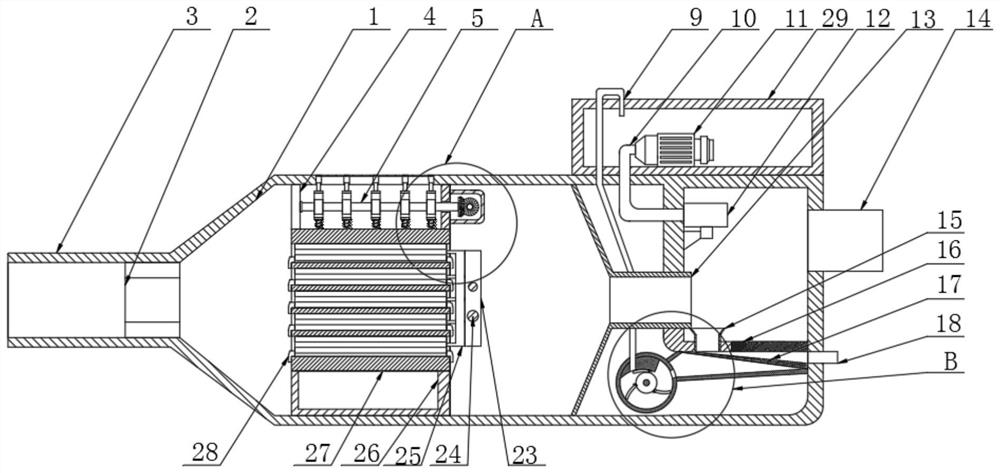

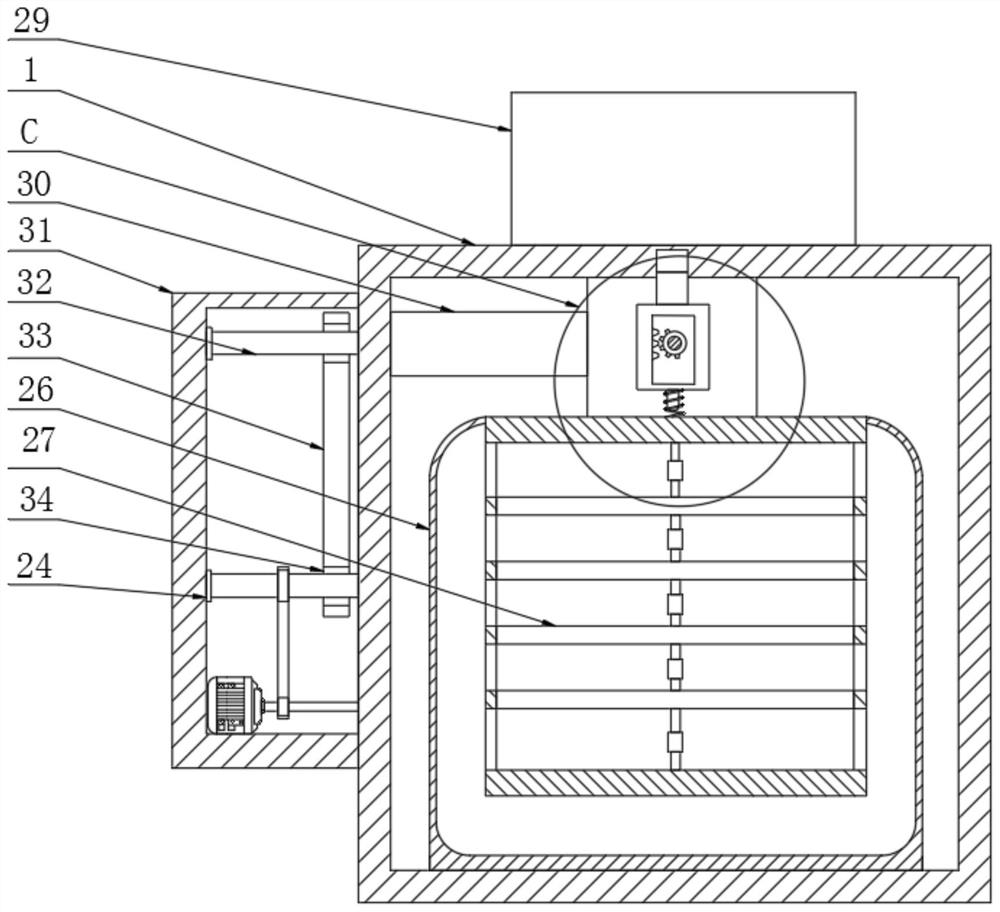

[0029] Embodiment 1, with reference to attached Figure 1-7 , a wet-type high-voltage electrostatic device provided by the present invention includes a housing 1, a water tank 29 is fixed on the top of the housing 1, a protective cover 31 is provided on one side of the housing 1, and a water tank 29 is fixed inside the housing 1. There is a smoke outlet 13, the housing 1 is fixed with a housing 2, and the housing 1 is equipped with a wet dust removal cycle mechanism and an electrostatic dust removal mechanism;

[0030] The wet dedusting cycle mechanism includes a support plate 40, the support plate 40 is fixed inside the housing 1, the smoke outlet 13 runs through the support plate 40, and the top side of the support plate 40 is fixed with a water spray head 12 , the bottom of the support plate 40 is fixedly embedded with a water receiving funnel 15, and one side of the water spray head 12 is fixedly connected with a second connecting pipe 10, and the second connecting pipe 10...

Embodiment 2

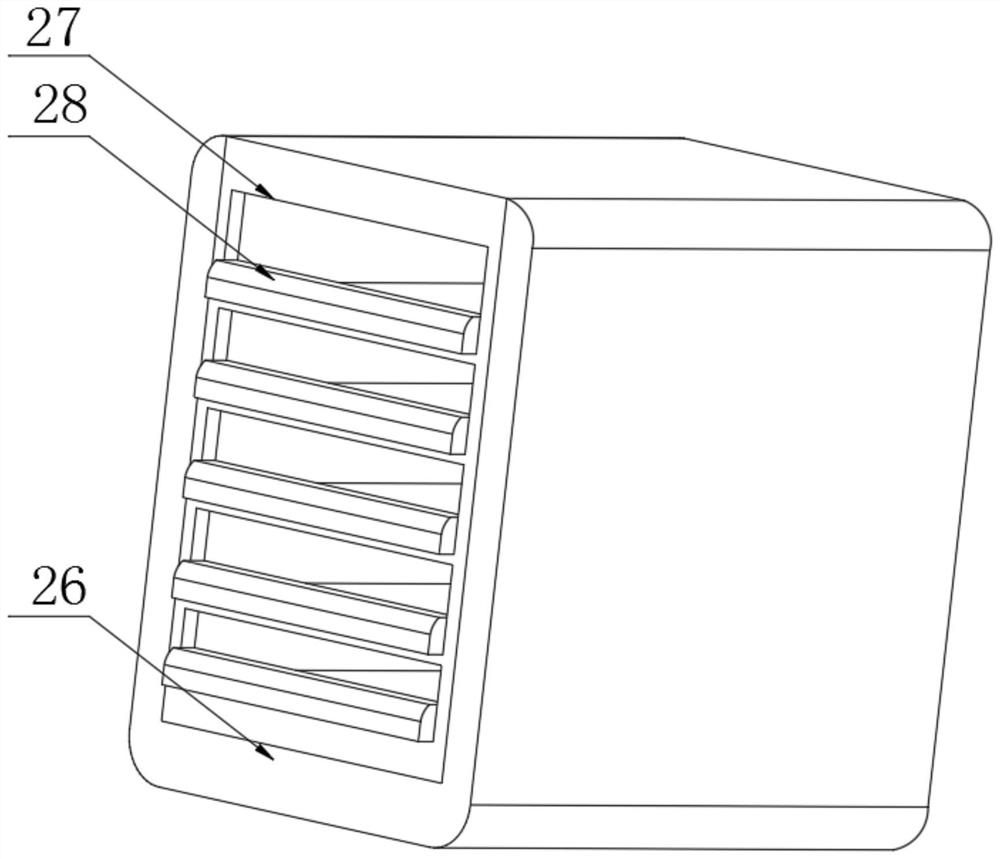

[0039] Embodiment 2, with reference to attached Figure 8 , a wet high-voltage electrostatic device provided by the present invention, the dust removal assembly includes a second brush 22, the second brush 22 is arranged inside the dust collecting electrode plate 27, and one side of the second brush 22 is fixedly connected to Bearing block 23 is arranged.

[0040] The application process of the present invention is as follows: when using the present invention, the present invention is connected to an external power supply, and when the device is started, smoke and dust enter the casing 1 from the smoke inlet 3, and when entering, the electric field force generated by the casing 2 will cause the smoke and dust particles to carry Electric charge, when entering dust-collecting electrode plate 27, soot can be absorbed by dust-collecting electrode plate 27, drives drive rod 36 to rotate when motor 38 starts, and drive rod 36 rotates and drives second pulley 37 to rotate, and second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com