Polymer-based positive temperature coefficient thermistor composite material and preparation method and application thereof

A technology of composite materials and polymers, applied in the direction of resistors with positive temperature coefficients, resistors, non-adjustable metal resistors, etc., can solve the problems of inability to respond to battery temperature changes in time, loss of function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

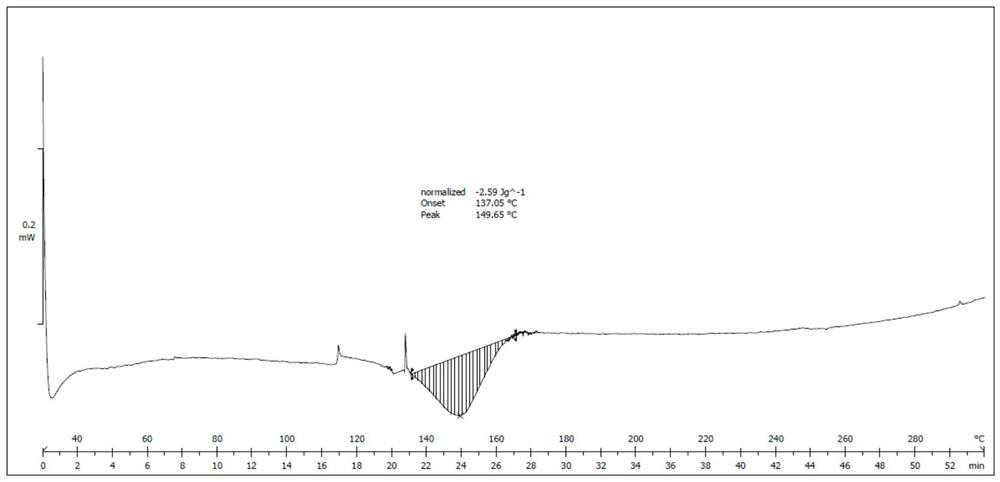

Image

Examples

preparation example Construction

[0052] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0053] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

Embodiment 1

[0055] Step 1. Add PVDF powder and methacrylate into nitrogen methylpyrrolidone (NMP), stir evenly, the stirring speed is 500r / min, and the stirring time is 8h. After stirring, let it stand for 72h to fully dissolve the PVDF. The mass ratio of the PVDF powder and NMP is 1:10. Methacrylate accounted for 10 wt% of the total mass of the polymer.

[0056] Step 2: Add the conductive agent Super-P to the prepared solution in Step 1, and ball mill for 30 minutes to prepare PPTC slurry. The mass ratio of the conductive agent Super-P and PVDF powder is 1:5.

[0057] Step 3: Coating the prepared PPTC slurry on both sides of the aluminum foil with a thickness of 10 μm to prepare a PPTC positive current collector, the thickness of the coating layer on one side is 2 μm. The negative electrode current collector is only copper foil.

[0058] Step 4, prepare lithium ion battery, the method is as follows:

[0059] (1) Negative electrode active material artificial graphite, conductive agent...

Embodiment 2

[0064] Others are the same as in Example 1, the only difference is that in step 1, methacrylate accounts for 30wt% of the total mass of the polymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com