Rotor punching sheet, rotor iron core, motor rotor, assembling method and motor

A technology of rotor punching and motor rotor, which is applied in the field of motor rotor and assembly method, rotor core, motor, and rotor punching, and can solve the problems of reducing the degree of magnetic flux leakage of the outer circle magnetic bridge of the rotor, complex production and assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

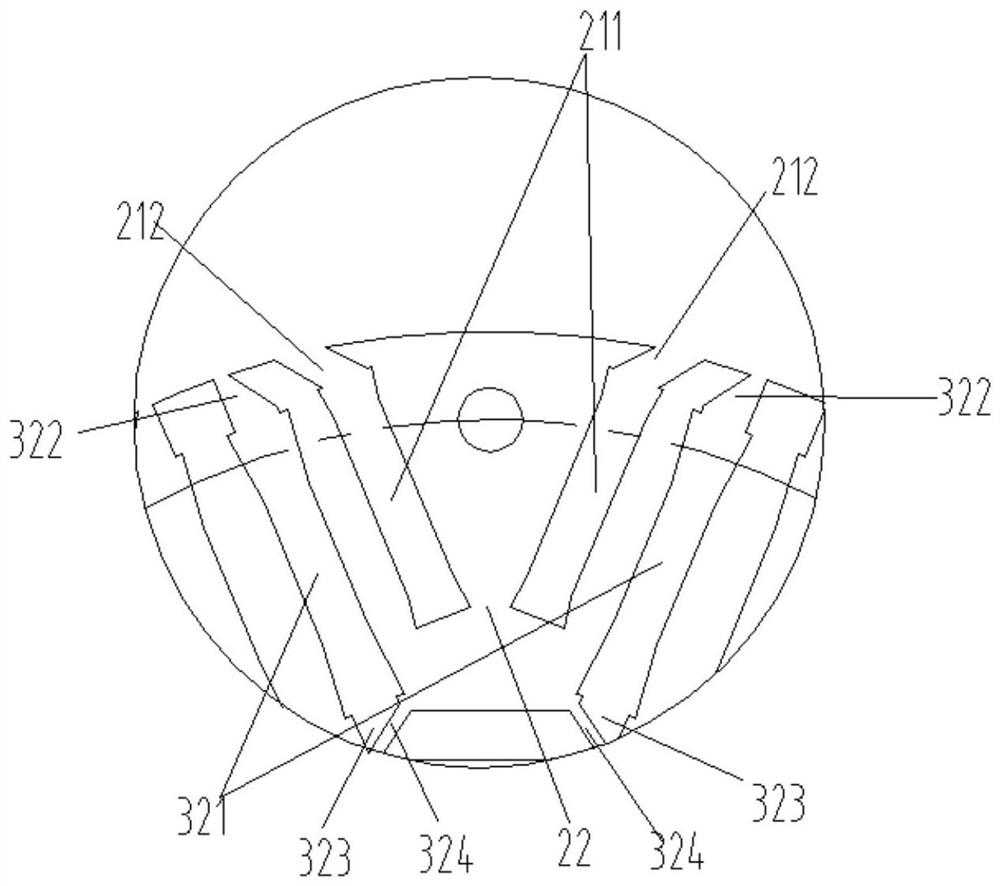

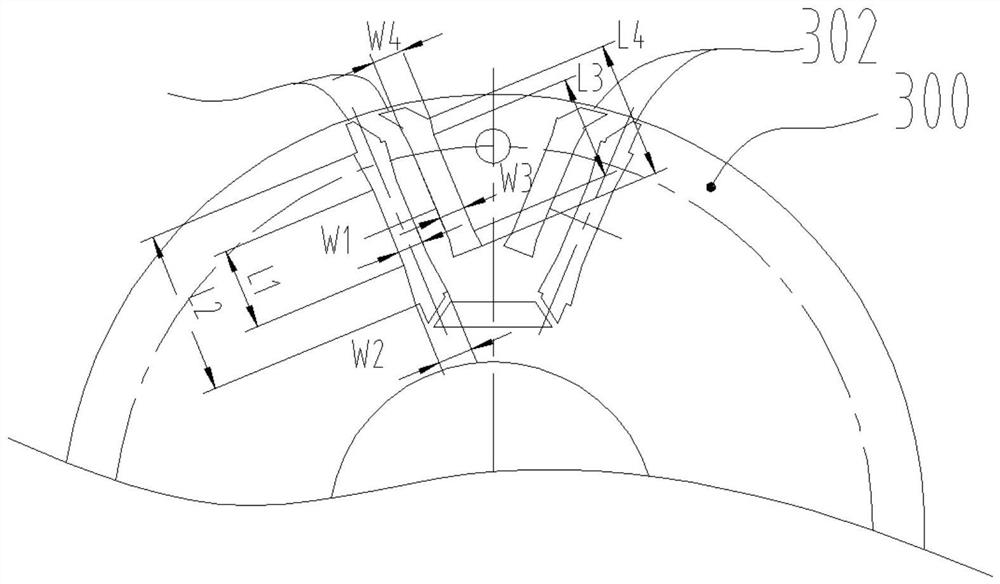

[0048] see in conjunction Figure 1 to Figure 11 As shown, according to the embodiment of the present invention, a rotor stamping is provided, which includes a stamping body 1, and the stamping body 1 has a plurality of magnetic pole forming regions corresponding to the motor rotor poles, and each magnetic pole forming region A first magnetic barrier groove 2 is configured on the punch body 1, and the first magnetic barrier groove 2 is symmetrical about the d-axis in the corresponding magnetic pole forming region and forms a first magnetic barrier groove facing the outer peripheral side of the punch body 1 Open angle structure, the bottom of the first magnetic barrier slot 2 has a first magnetic isolation bridge 22 on the d-axis, and the first magnetic barrier slot 2 includes two first sides symmetrical about the d-axis Extending magnetic barrier slot 21, the first laterally extending magnetic barrier slot 21 includes a first magnetic steel slot 211 and a first air slot 212 ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com