Customized woodworking furniture flexible production line fault diagnosis system

A fault diagnosis system and flexible production line technology, applied in manufacturing computing systems, comprehensive factory control, biological neural network models, etc., can solve production line shutdown, time-consuming, manpower, material resources, and affect the production progress of users' wooden doors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

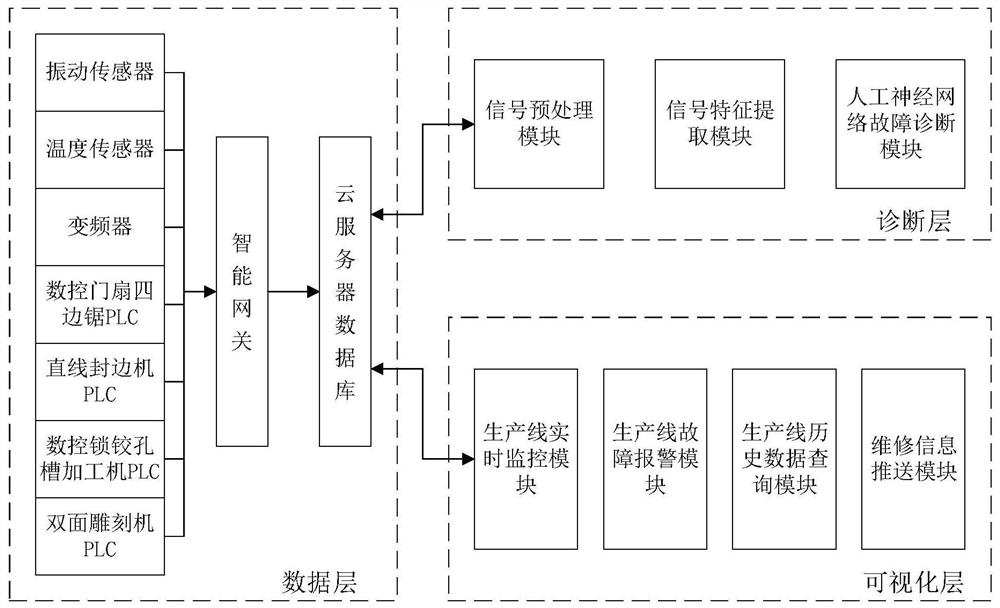

[0022] combine figure 1 According to the invention, a fault diagnosis system for a flexible production line of customized woodworking furniture is divided into three layers, including a data layer, a diagnosis layer, and a visualization layer.

[0023] In the data layer, the intelligent gateway collects the data generated during the operation of the customized woodworking furniture flexible production line in real time and uploads it to the cloud server database. The intelligent gateway collects the frequency converter data such as current value and voltage value of 4 main processing equipment of the production line through the RS485 interface in real time, including CNC door leaf four-side saw, linear edge banding machine, CNC lock reamer slot processing machine, and double-sided engraving machine. Install CA-YD-187 piezoelectric acceleratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com