A filter structure of an air conditioner evaporator for construction machinery

A technology of engineering machinery and filtration structure, which is applied in evaporator/condenser, dispersed particle filtration, refrigerator, etc., can solve the problem of time-consuming and achieve the effect of rapid collection and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

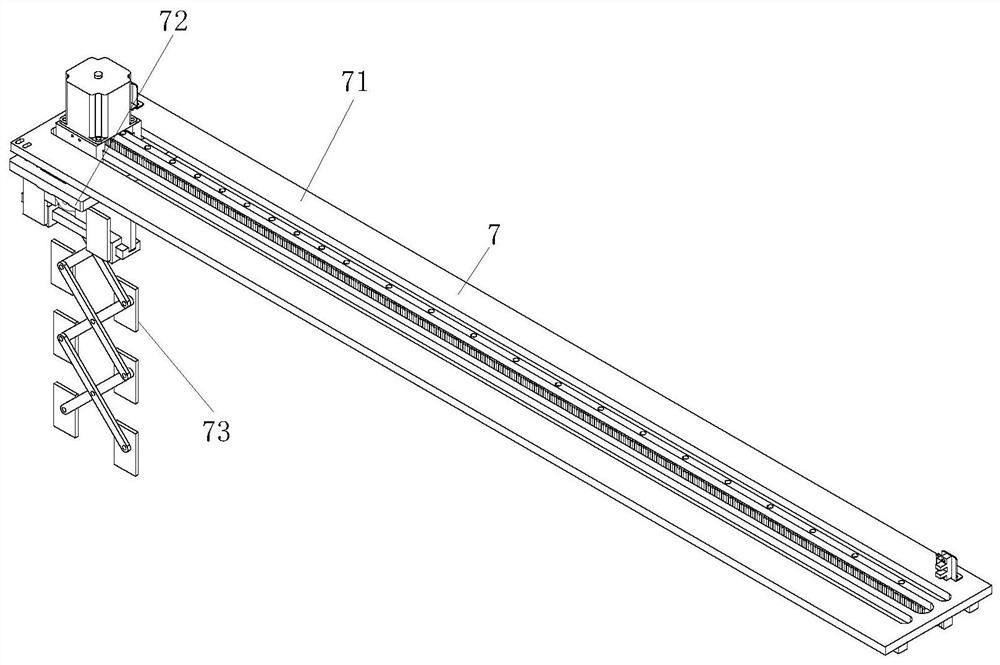

[0033] see figure 1 , the present invention provides an air conditioner evaporator filter structure for construction machinery through improvement, including a fixed frame 1, a filter element 5, a groove 6, a telescopic cleaning mechanism 7 and a collection mechanism 8, and a control panel is arranged on the left side of the front end of the fixed frame 1 2. A button 3 is installed on the upper end of the control panel 2, a power wire 4 is fixed on the left end of the fixed frame 1, a filter element 5 is arranged in the middle of the fixed frame 1, a groove 6 is opened at the lower end of the fixed frame 1, and the telescopic cleaning mechanism 7 is installed and fixed on the fixed The inner upper end of the frame 1, and the telescopic cleaning mechanism 7 is in contact with the front end of the filter element 5, and the collection mechanism 8 is installed on the bottom of the fixed frame 1.

[0034] see figure 2 , the present invention provides an air-conditioning evaporato...

Embodiment 2

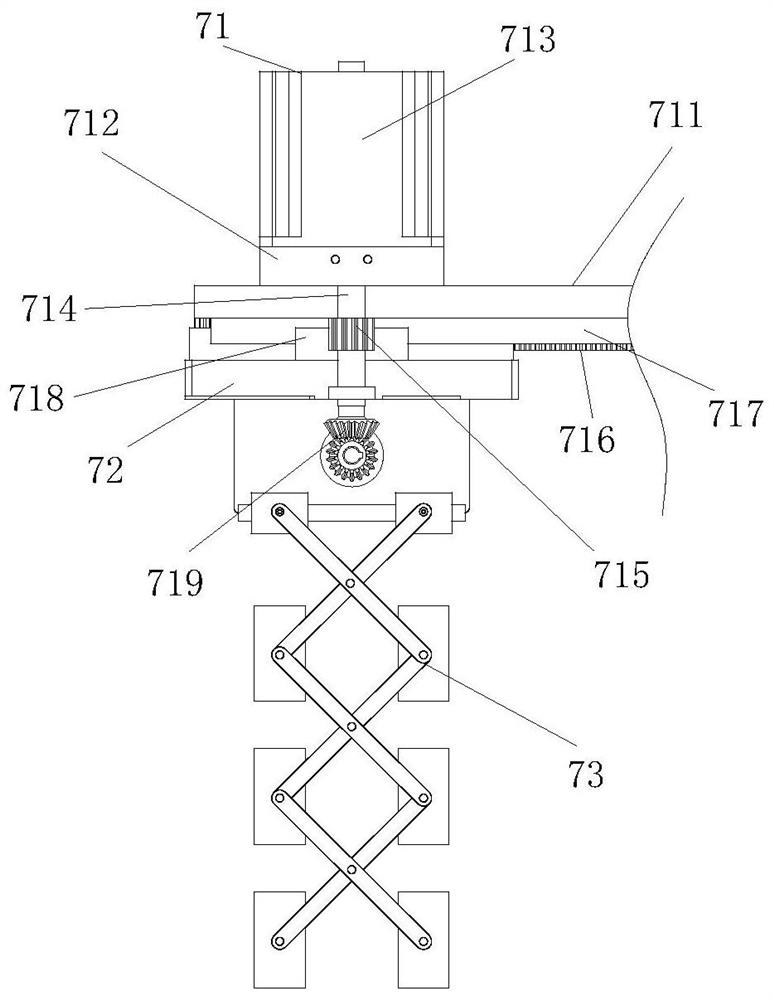

[0040] The present invention provides an air conditioner evaporator filter structure for engineering machinery through improvement. The second sliding sleeve 736 and the first sliding sleeve 733 have the same size, and the upper ends of the second sliding sleeve 736 and the first sliding sleeve 733 are both provided with grooves. , which is beneficial to make the second sliding sleeve 736 and the first sliding sleeve 733 move smoothly, the upper end of the brush plate 739 is provided with a brush head 7391, and the brush head 7391 is in contact with the front end of the filter element 5, which is beneficial to cleaning the filter element 5 The right rear end of the top of the horizontal plate 711 is provided with a limiting block 7111, which is beneficial to play the role of limiting the moving frame 712.

[0041] The present invention provides an air conditioner evaporator filter structure for engineering machinery through improvement, and its working principle is as follows; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com