Melt control in-situ synthesis aluminum matrix composite system with continuous treatment function

An aluminum-based composite material, an in-situ self-generating technology, which is applied in the field of aluminum-based composite materials and can solve problems such as high temperature oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

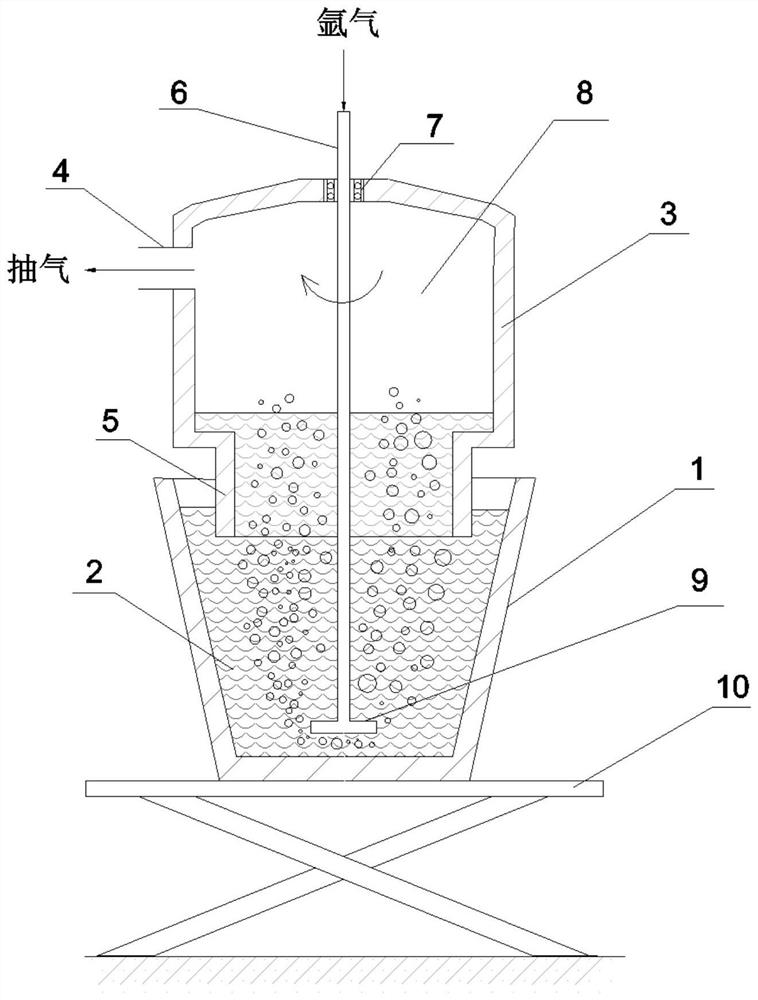

[0044] Such as figure 1 As shown, the pure aluminum or aluminum alloy substrate is melted at 700-760° C., the aluminum melting furnace 1 containing the aluminum melt 2 is placed on the hydraulic lifting table 10, and reaction salts and reaction aids are added for reaction. The hydraulic lifting table 10 is raised so that the dip tube 5 of the vacuum bag 3 arranged above the aluminum melting furnace 1 is immersed into the aluminum melt 2 . The vacuum chamber 8 of the vacuum bag 3 is evacuated through the pumping port 4, so that the aluminum melt 2 enters the vacuum bag 3 under atmospheric pressure.

[0045]At the same time, the aluminum melt is sprayed with argon rotation: the graphite rotor is lowered, and the rotating rod 6 of the graphite rotor passes through the sealed bearing 7 arranged on the top of the vacuum bag 3, passes through the vacuum chamber 8, and inserts the nozzle 9 into the bottom of the aluminum melt 2. At the bottom, argon gas is blown in through the middl...

Embodiment 2

[0054] Such as figure 2 As shown, the pure aluminum or aluminum alloy substrate is melted at 700-760°C, the aluminum melt 2 is placed in the aluminum melting furnace 1, and reaction salts and reaction aids are added for reaction. The immersion tube 5 of the vacuum bag 3 arranged above the aluminum melting furnace 1 is immersed into the aluminum melt 2 . The vacuum chamber 8 of the vacuum bag 3 is evacuated through the pumping port 4, so that the aluminum melt 2 enters the vacuum bag 3 under atmospheric pressure.

[0055] At the same time, the aluminum melt is sprayed with argon rotation: the graphite rotor is lowered, and the rotating rod 6 of the graphite rotor passes through the sealed bearing 7 arranged on the top of the vacuum bag 3, passes through the vacuum chamber 8, and inserts the nozzle 9 into the bottom of the aluminum melt 2. At the bottom, argon gas is blown in through the middle hole of the rotating rod 6 and ejected from the rotating nozzle 9. The formed bubbl...

Embodiment 3

[0065] Such as image 3 As shown, the pure aluminum or aluminum alloy substrate is melted at 700-760°C, the aluminum melt 2 is placed in the aluminum melting furnace 1, and reaction salts and reaction aids are added for reaction. The immersion tube 5 of the vacuum bag 3 arranged above the aluminum melting furnace 1 is immersed into the aluminum melt 2 . The vacuum chamber 8 of the vacuum bag 3 is evacuated through the pumping port 4, so that the aluminum melt 2 enters the vacuum bag 3 under atmospheric pressure.

[0066] At the same time, the aluminum melt is sprayed with argon rotation: the graphite rotor is lowered, and the rotating rod 6 of the graphite rotor passes through the sealed bearing 7 arranged on the top of the vacuum bag 3, passes through the vacuum chamber 8, and inserts the nozzle 9 into the bottom of the aluminum melt 2. At the bottom, argon gas is blown in through the middle hole of the rotating rod 6 and ejected from the rotating nozzle 9. The formed bubble...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com