Compound polysaccharide sodium hyaluronate gel and preparation method thereof

A technology of sodium hyaluronate and complex polysaccharides, which is applied in pharmaceutical formulations, prostheses, drug delivery, etc., and can solve problems such as insufficient smoothness of the surface of gel particles, adverse reactions, and poor viscoelasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

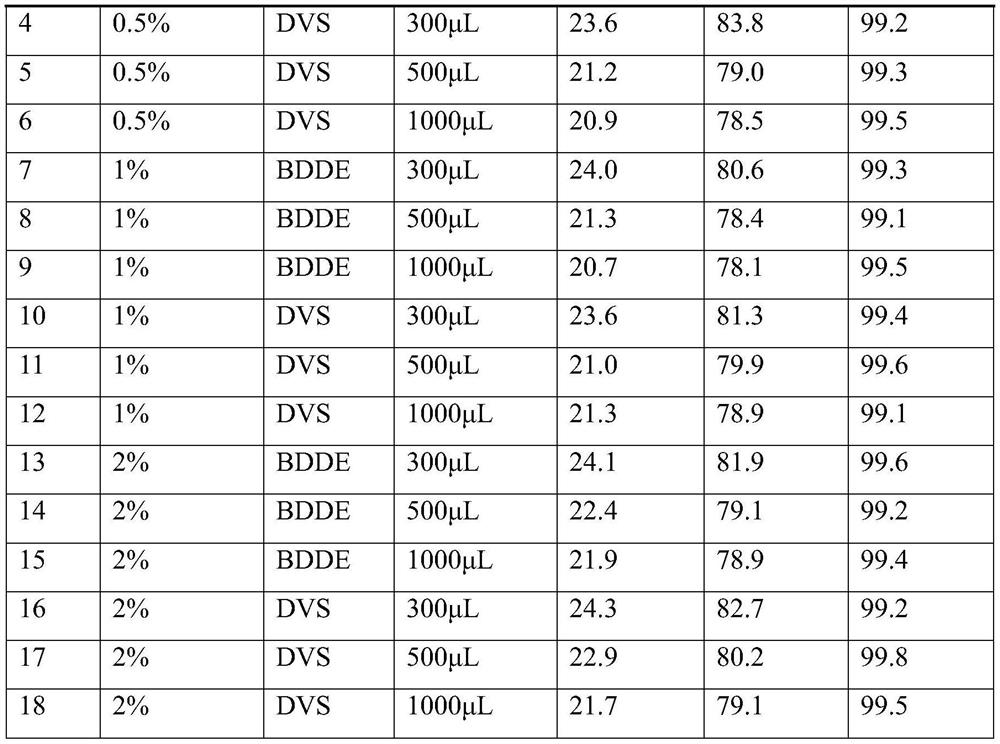

Examples

Embodiment 1

[0048] Prepare 30 mL of sodium hydroxide solution with a mass fraction of 1%, add 0.3 g of sodium alginate and stir evenly, then add 5.4 g of sodium hyaluronate powder into the mixed solution, and stir evenly until it becomes transparent. Add 500 μL of BDDE to the above solution, stir evenly for 30 minutes, take it out and let it stand in a water bath at 30°C for 5 hours. After thermal cross-linking is completed, transfer it to an environment at 4°C to continue cross-linking for 20 hours. After the cross-linking is completed, block gel is obtained. Divide the block gel into uniform small pieces, add 800mL of prepared PBS buffer to swell, change the buffer every two hours until the pH of the gel is around 7.0, the osmotic pressure is about 300mOsmol / L, and the gel weight It is 250g, which is the end point of swelling at this time. The swollen gel was homogenized into a composite gel with uniform particles and certain viscoelasticity using a homogenizer. The homogenization time ...

Embodiment 2

[0050] Prepare 30 mL of sodium hydroxide solution with a mass fraction of 1%, add 1.5 g of sodium alginate and stir evenly, then add 5.4 g of sodium hyaluronate powder into the mixed solution, and stir evenly until it becomes transparent. Add 500 μL of BDDE to the above solution, stir evenly for 30 minutes, take it out and let it stand in a water bath at 30°C for 5 hours. After thermal cross-linking is completed, transfer it to an environment at 4°C to continue cross-linking for 20 hours. After the cross-linking is completed, block gel is obtained. Divide the fast gel into uniform small pieces, add 800mL of prepared PBS buffer to swell, change the buffer every two hours until the pH of the gel is around 7.0, the osmotic pressure is about 300mOsmol / L, and the gel weight It is 250g, which is the end point of swelling at this time. The swollen gel was homogenized into a composite gel with uniform particles and certain viscoelasticity using a homogenizer. The homogenization time w...

Embodiment 3

[0052] Prepare 30 mL of sodium hydroxide solution with a mass fraction of 1%, add 1.5 g of sodium alginate and stir evenly, then add 5.4 g of sodium hyaluronate powder into the mixed solution, and stir evenly until it becomes transparent. Add 500 μL of BDDE to the above solution, stir evenly for 30 minutes, take it out and let it stand in a water bath at 30°C for 5 hours. After the thermal crosslinking is completed, transfer it to an environment at 4°C to continue crosslinking for 10 hours to obtain a block gel. Divide the block gel into uniform small pieces, add 800mL of prepared PBS buffer to swell, change the buffer every two hours until the pH of the gel is around 7.0, the osmotic pressure is about 300mOsmol / L, and the gel weight It is 250g, which is the end point of swelling at this time. The swollen gel was homogenized into a composite gel with uniform particles and certain viscoelasticity using a homogenizer. The homogenization time was 30 minutes, the speed of the homo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com