Sulfonated conjugated microporous polymer as well as preparation method and application thereof

A conjugated microporous, polymer technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve the problems of large amount of sludge, low adsorption capacity of adsorbents, difficult post-processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

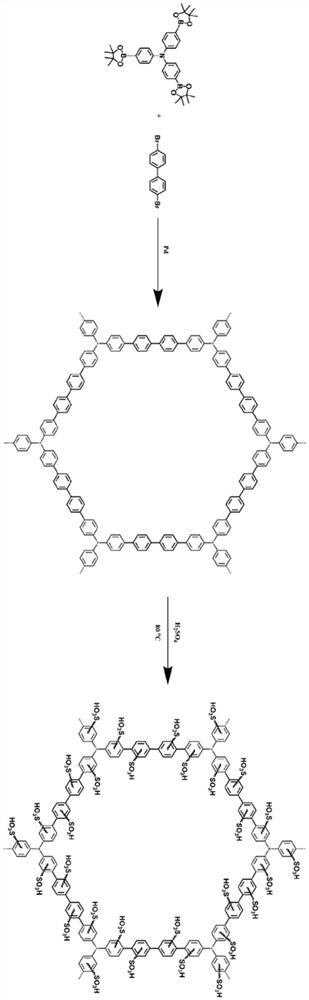

[0043] Embodiment 1: a kind of sulfonated conjugated microporous polymer and preparation method thereof, such as figure 1 shown.

[0044] Product 1:

[0045] 1) Using tris(4-boronic acid pinacol ester phenyl)amine and 4,4-dibromobiphenyl under the catalysis of zero-valent tetrakistriphenylphosphorous palladium in N,N-dimethylformamide and 2M carbonic acid Suzuki polymerization reaction is carried out in a moderate temperature mixed solvent of potassium aqueous solution to obtain nano-scale conjugated microporous polymer;

[0046] Mix 100 mg of tris(4-boronic acid pinacol ester phenyl)amine and 100 mg of 4,4-dibromobiphenyl with equal functional group ratio in 10 mL of dimethylformamide and 2M potassium carbonate aqueous solution under the catalysis of 5 mg of zero-valent metal palladium In 3mL mixed solvent, react at 90°C for 24 hours to form nanoscale conjugated microporous polymer.

[0047] 2) performing a sulfonation reaction on the conjugated microporous polymer in step...

Embodiment 2

[0060] 1. Experimental materials

[0061] The sulfonated conjugated microporous polymer and methylene blue solution prepared under the conditions of product 3 in Example 1.

[0062] 2. Experimental method

[0063] 2.1 Weigh 5 mg of sulfonated conjugated microporous polymer and put it into a methylene blue solution with a concentration of 50 mg / L, place it at a temperature of 25°C, adjust the pH value to 7, stir well, and wait for the adsorption to complete.

[0064] 2.2 Weigh 1 g of sulfonated conjugated microporous polymer and put it into a methylene blue solution with a concentration of 400 mg / L, place it at 25°C, adjust the pH value to 7, stir well, and wait for the adsorption to complete.

[0065] 2.3 Weigh 1 g of sulfonated conjugated microporous polymer and put it into a methylene blue solution with a concentration of 200 mg / L, place it at a temperature of 25°C, adjust the pH value to 7, stir well, and wait for the adsorption to complete.

[0066] 3. Experimental resul...

Embodiment 3

[0069] 1. Experimental materials

[0070] The conditions of product 3 in Example 1 prepared sulfonated conjugated microporous polymer, potassium bromide, methylene blue solution, and hydrochloric acid solution.

[0071] 2. Experimental method

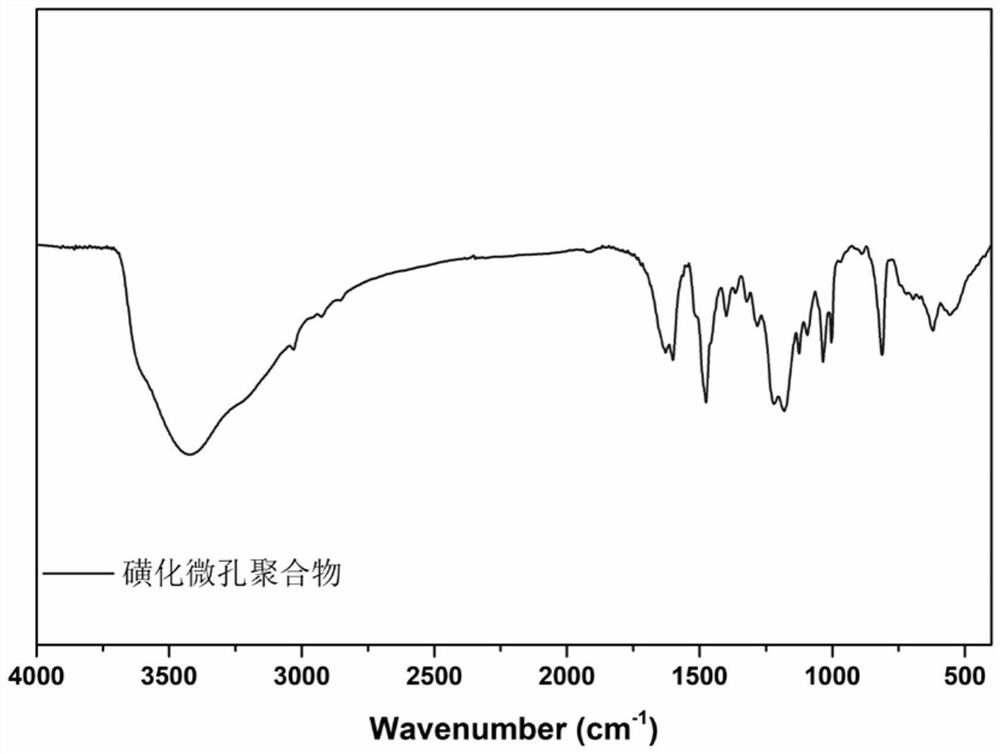

[0072] Infrared Spectrogram: Nexus-560 (Nicolet) infrared spectrometer was used for characterization, specifically: Weigh 5 mg of sulfonated conjugated microporous polymer, grind it fully with 100 mg of potassium bromide powder, and test it after tableting. The test wave number is 4000~400cm -1 .

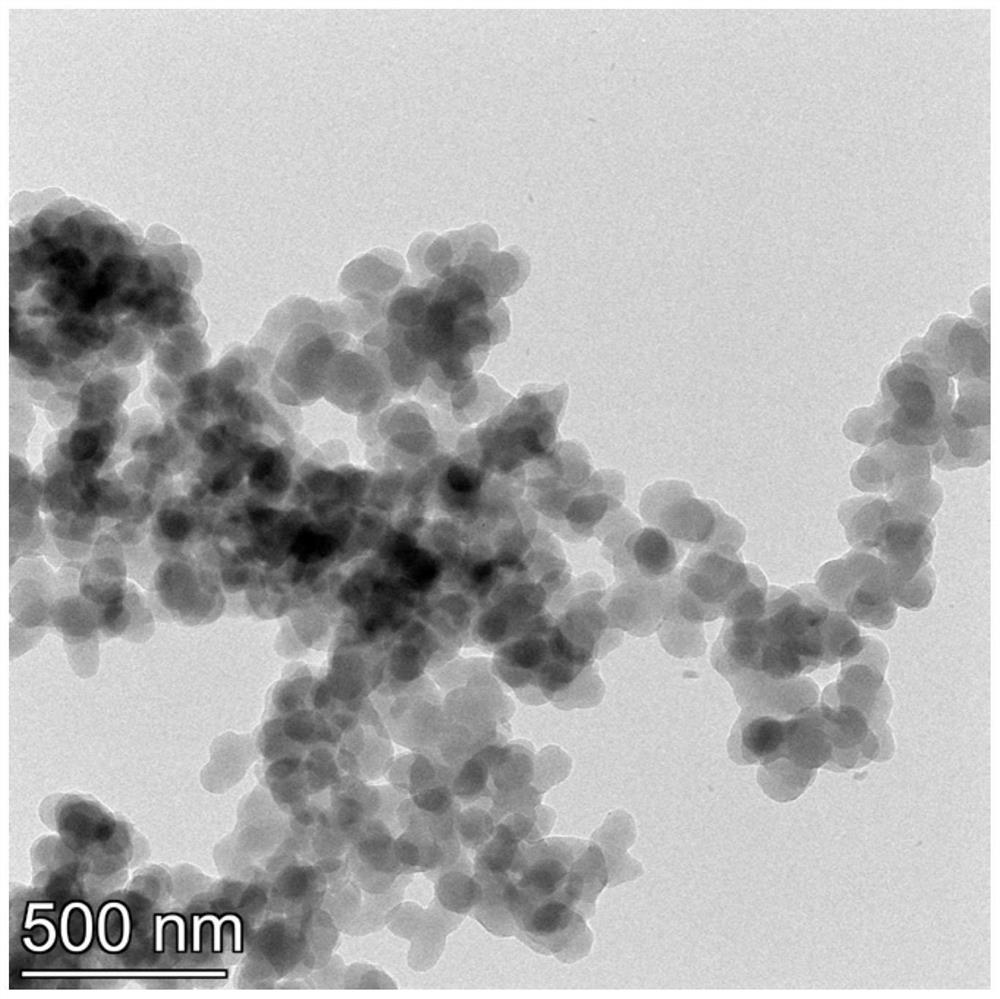

[0073] Transmission electron microscope: G20 JEM-2100F transmission electron microscope is used for testing, specifically: 2 mg of sulfonated conjugated microporous polymer is weighed, dispersed on a copper grid, and then characterized.

[0074] Adsorption effect: Weigh 5mg of sulfonated conjugated microporous polymer each time, then disperse in 20mL of 200mg / L different dye solutions, stir at 25°C until the adsorption is saturated, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com