Oily sludge treatment method

A treatment method and technology for oily sludge, applied in sludge treatment, water/sludge/sewage treatment, treatment of hydrocarbon oil, etc., can solve the problems of poor degradability of oily sludge, complicated process, and compatibilization of solidified products, etc. Achieve high catalytic activity and catalytic effect, lower reaction temperature, and reduce energy consumption requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

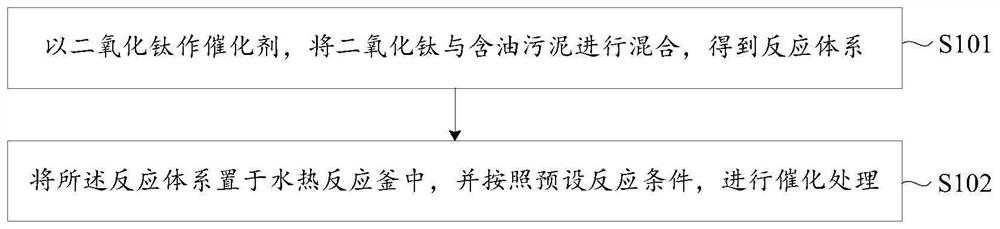

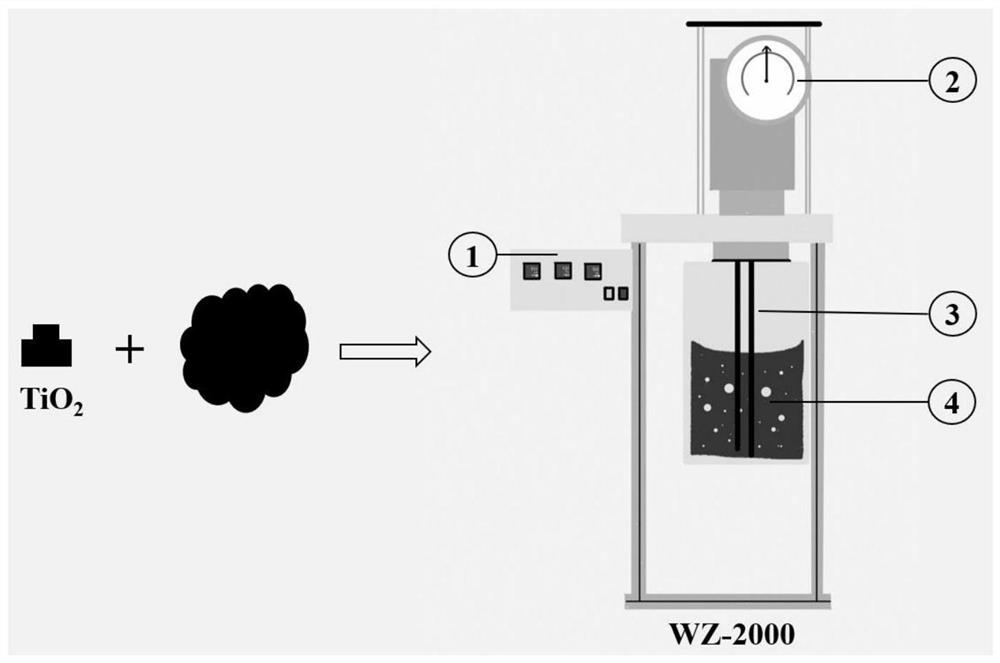

[0054] This implementation case designs the treatment effect of a method for treating oily sludge with titanium dioxide catalyzed hydrothermal reaction, which specifically includes the following steps:

[0055] The device for treating oily sludge by catalytic hydrothermal reaction with titanium dioxide catalyst is a hydrothermal reaction kettle. Stir the oily sludge evenly, and after there is no obvious water deposition, take 500g of oily sludge, and mix the commercialized nano-titanium dioxide with the stirred oily sludge according to the mass ratio of 1.5: 100 mixing, the temperature rise parameters of the reactor were set at a heating rate of 3°C / min, a stirring rate of 100r / min, a maximum reaction temperature of 230°C, and a reaction residence time of 30min. After the reaction was over, the reactor was closed and the temperature was naturally lowered to 100°C. About 300g of the mixture was taken and centrifuged at high temperature in a centrifuge with the centrifugation pa...

Embodiment 2

[0059] This implementation case designs the treatment effect of a method for treating oily sludge with titanium dioxide catalyzed hydrothermal reaction, which specifically includes the following steps:

[0060] The design of the titania catalyst to catalyze the hydrothermal reaction treatment of oily sludge is the same as in Example 1. The difference is that the mass ratio of titanium dioxide catalyst to oily sludge is 1:100.

[0061] The results of the treatment of oily sludge by the hydrothermal reaction catalyzed by the titanium dioxide catalyst are shown in Table 1: the dehydration efficiency of the oily sludge is 36.92%, the oil removal efficiency of the oily sludge is 42.81%, and the resource extraction efficiency of the oil is 46.71%.

Embodiment 3

[0063] This implementation case designs the treatment effect of a method for treating oily sludge with titanium dioxide catalyzed hydrothermal reaction, which specifically includes the following steps:

[0064] The design of the titania catalyst to catalyze the hydrothermal reaction treatment of oily sludge is the same as in Example 1. The difference is that the mass ratio of titanium dioxide catalyst to oily sludge is 2:100.

[0065] The results of the treatment of oily sludge by the hydrothermal reaction catalyzed by the titanium dioxide catalyst are shown in Table 1: the dehydration efficiency of the oily sludge is 36.14%, the oil removal efficiency of the oily sludge is 57.75%, and the resource extraction efficiency of the oil is 57.80%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dehydration rate | aaaaa | aaaaa |

| dehydration rate | aaaaa | aaaaa |

| dehydration rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com