Double-drive four-direction walking forward-moving transfer trolley

A technology for transporting vehicles and driving boxes, applied in the direction of lifting devices, etc., can solve the problems of ineffective rotation, difficulty in completing transfer work, and repeated and complicated operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

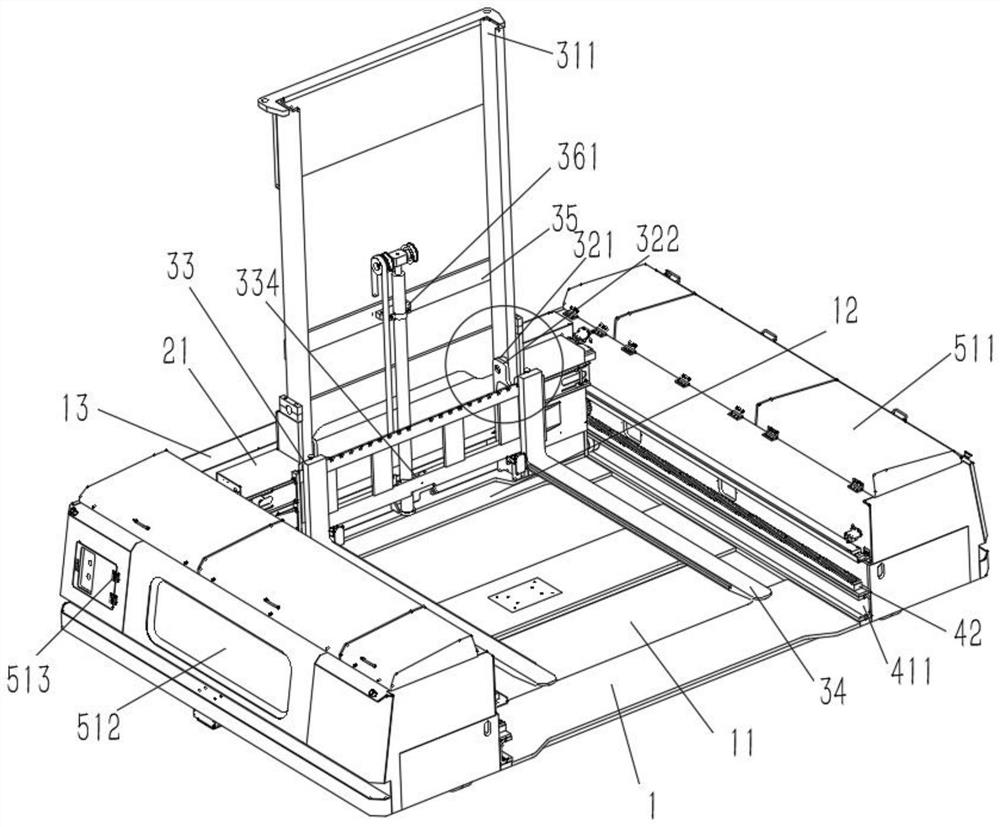

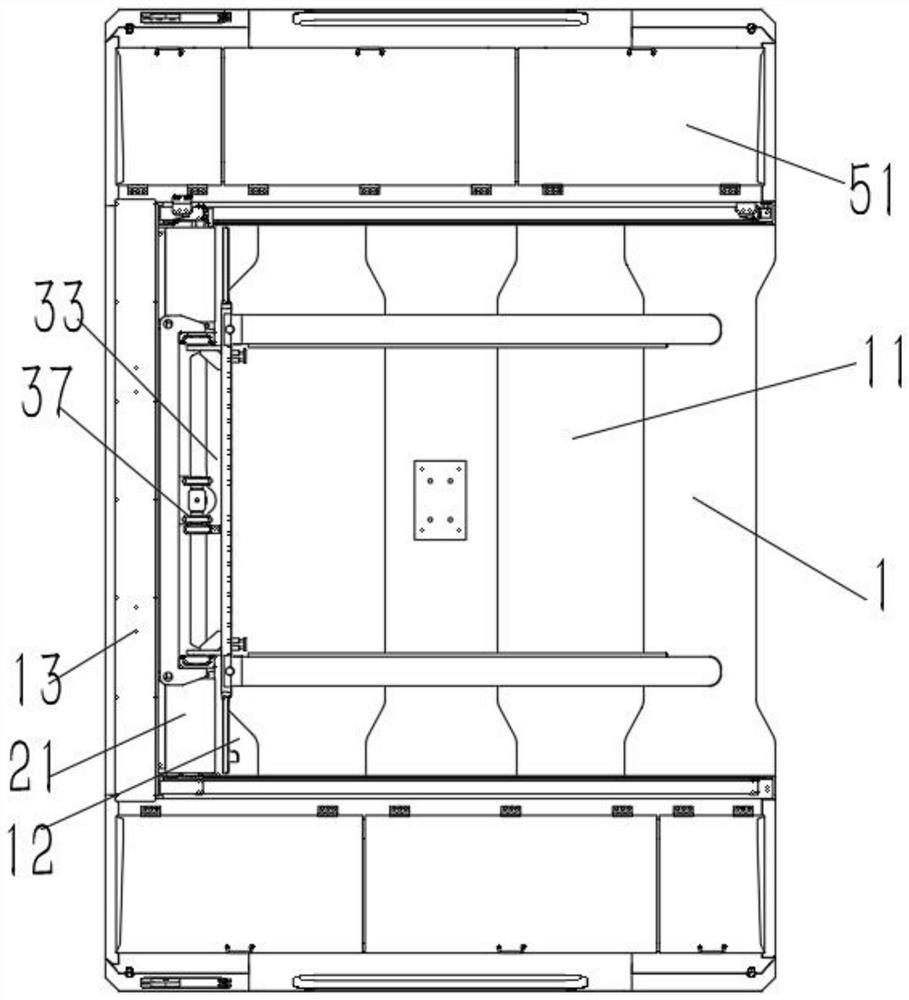

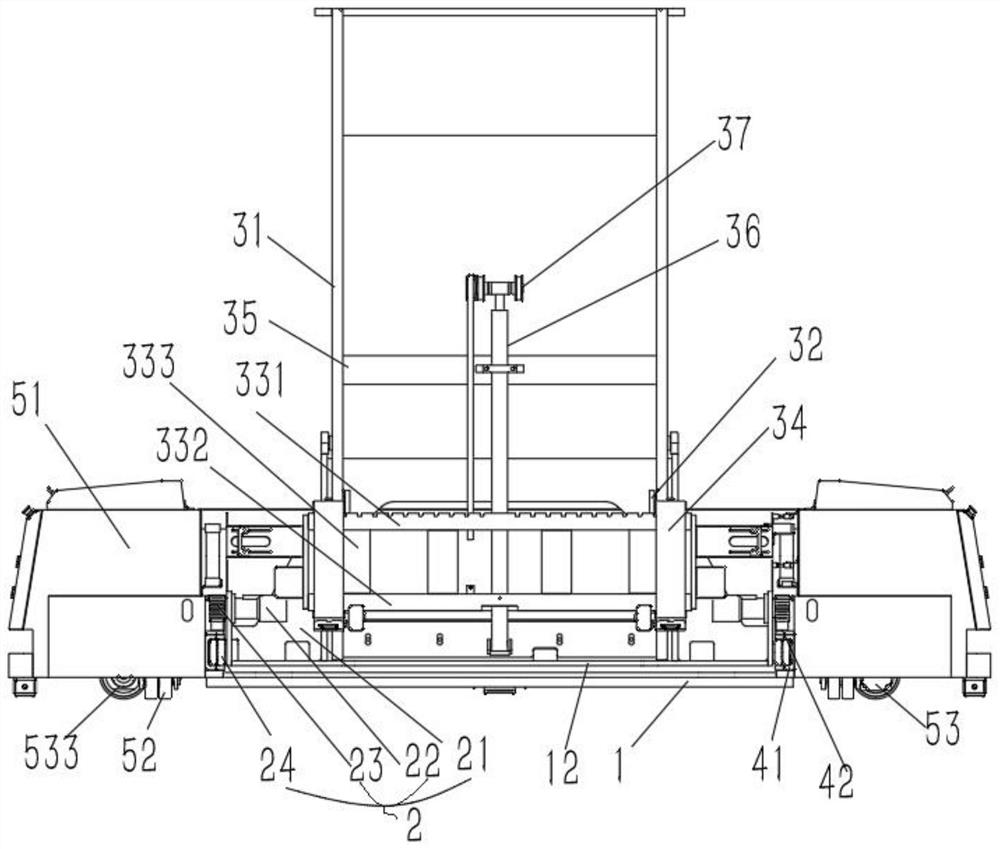

[0027] It is one of the specific implementation modes of the present invention: refer to the accompanying drawings.

[0028] In this embodiment, a forward transfer vehicle with dual-drive and four-way travel includes

[0029] A base 1, the upper surface of the base 1 is provided with multiple sets of reinforcing grooves 11, and the upper surface of the base 1 is movable with a slide plate 12;

[0030] The transmission assembly 2 includes two sets of transmission boxes 21, which are respectively symmetrically arranged at the two ends of the slide plate 12 located on the upper surface of the base 1. The two transmission boxes 21 are symmetrically provided with transmission parts 22, and the two transmission parts 22 The output end protrudes from the transmission box 21 and is provided with a driving gear 23, and the opposite outer bottom of the transmission box 21 is provided with a rolling wheel 24;

[0031] The lifting mechanism is located on the slide plate 12 and is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com