A kind of adjustable passenger car seat sub-package transfer material car

An adjustable, passenger car technology that can be used in motor vehicles, transportation and packaging to save production space, solve seat transfer problems, and have a suitable inclination angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

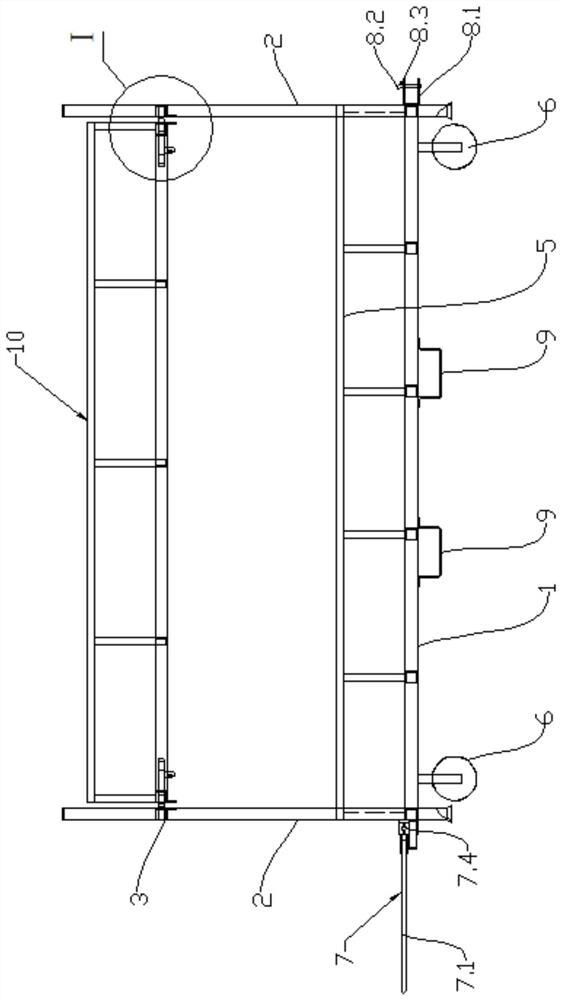

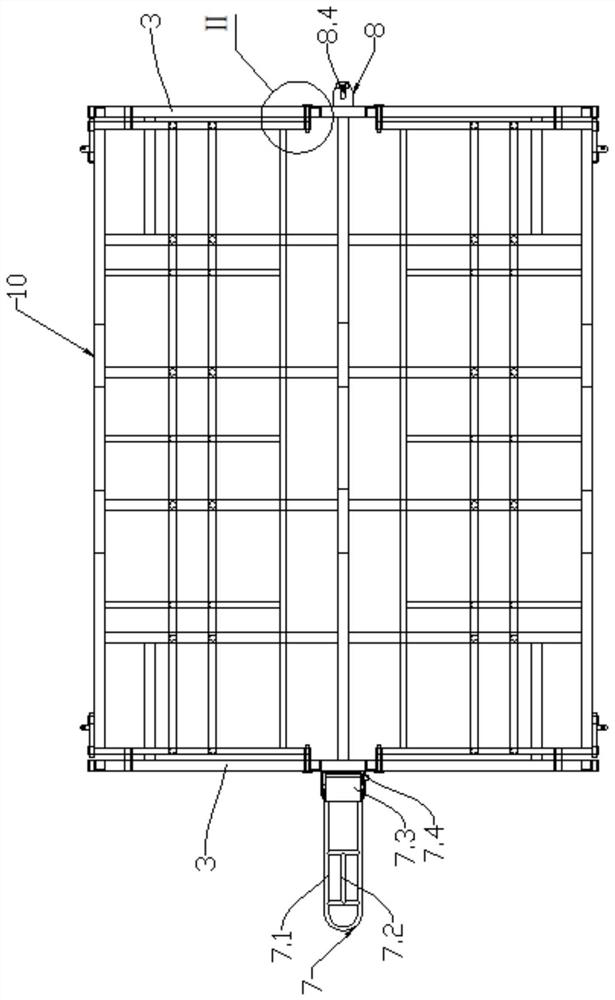

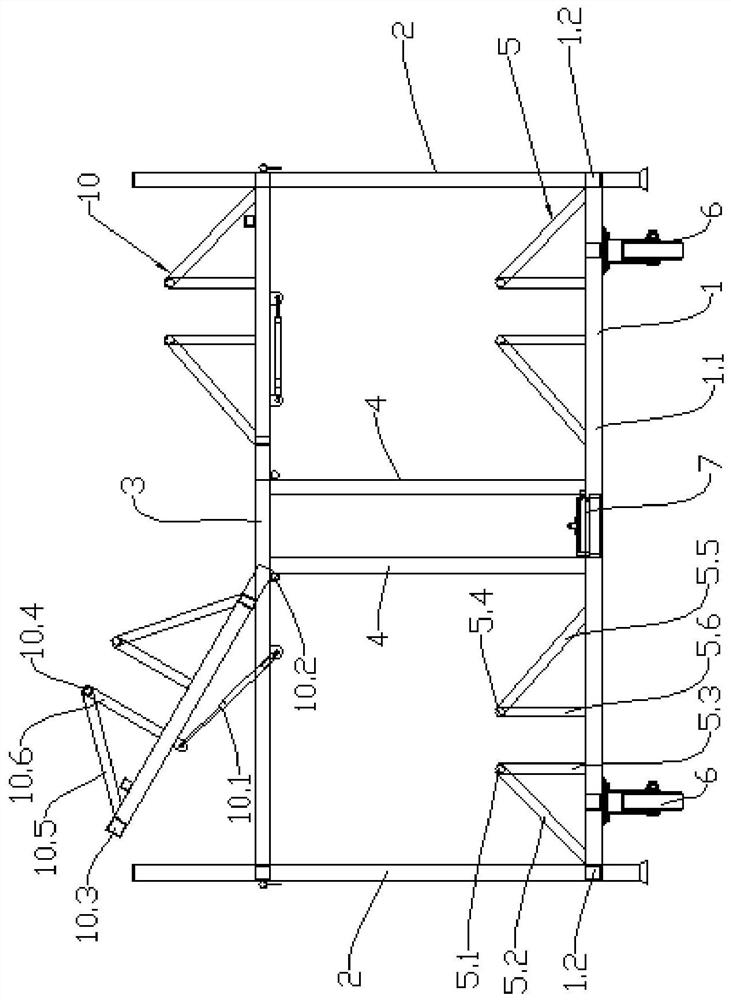

[0026] Such as Figure 1~3 In the shown embodiment, an adjustable passenger car seat sub-package transfer material car mainly includes a lower fixed frame 1, the four corners of the lower fixed frame 1 are respectively vertically provided with vertical poles 2, and the laterally adjacent ones of the four vertical poles 2 A fixed beam 3 is welded between the tops of the two poles 2 .

[0027] Such as figure 1 with image 3 In the shown embodiment, the lower fixed frame 1 is a frame structure, including a plurality of cross beams parallel to each other and a plurality of longitudinal beams 1.2 perpendicular to the cross beams 1.1, and a plurality of cross beams 1.1 and a plurality of longitudinal beams 1.2 are welded to each other to form a frame structure.

[0028] Such as figure 1 with image 3 In the shown embodiment, a plurality of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com