Electric truss type intelligent assembly workstation

A truss-type, workstation technology, applied in the field of machinery, can solve problems such as hoisting space interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

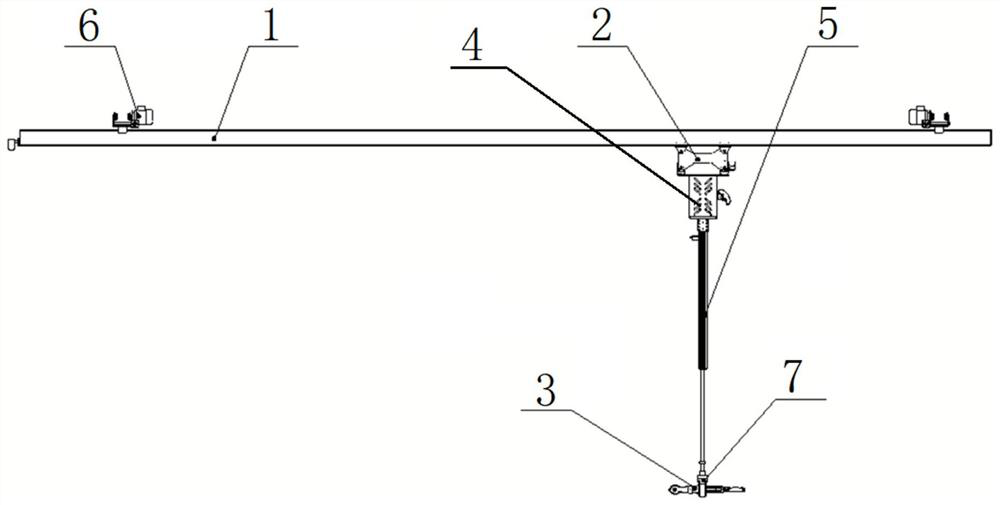

[0031] Such as figure 1 As shown, the present embodiment provides an electric truss type intelligent assembly workstation, including a plurality of KBK cantilever beams 1, a plurality of moving pulleys 2, a plurality of wired electric servo torque wrenches 3 and a plurality of rectangular tube anti-torque booster arms; The tackle 2 is arranged on the KBK suspension beam 1, and the rectangular tube anti-torsion booster arm includes a spring balancer 4 arranged on the moving tackle 2 and a rectangular tube reaction arm 5 arranged on the spring balancer 4 . The wired electric servo torque wrench 3 is arranged at one end of the rectangular tube reaction arm 5, and according to the gravity of the wired electric servo torque wrench 3, the purpose of offsetting the gravity of the wired electric servo torque wrench 3 is achieved by adjusting the elastic force of the spring balancer 4 , reduce the labor intensity of the workers, and eliminate the reaction force generated when the wire...

Embodiment 2

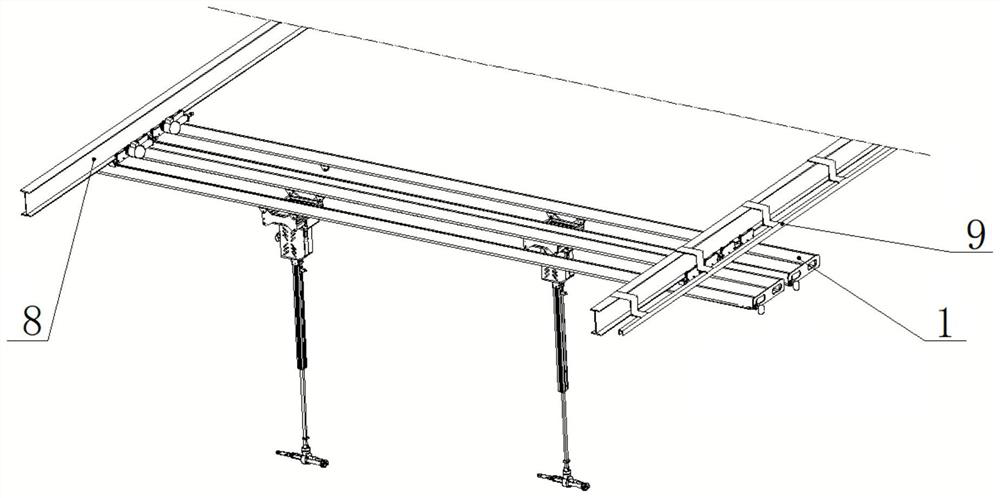

[0036] This embodiment provides an electric truss-type intelligent assembly workstation, the electric truss-type intelligent assembly workstation also includes an I-shaped track 8, and the motor drive assembly 6 is provided with a guide wheel, the guide wheel and the I-shaped track 8 are used together to make the motor drive assembly 6 move along the I-shaped track 8. The I-shaped track 8 spans two maintenance lines and covers the entire work area. The main task is to provide space for the electric truss frame to walk on. Both ends of the I-shaped track 8 are provided with limiting mechanisms. Such as image 3 As shown, the electric truss-type intelligent assembly workstation also includes a carbon brush, and one side of the I-shaped track 8 is provided with a trolley line 9 used in conjunction with the carbon brush. When the carbon brush and the trolley line 9 sliding contact , provide power for the electric truss-type intelligent assembly workstation.

Embodiment 3

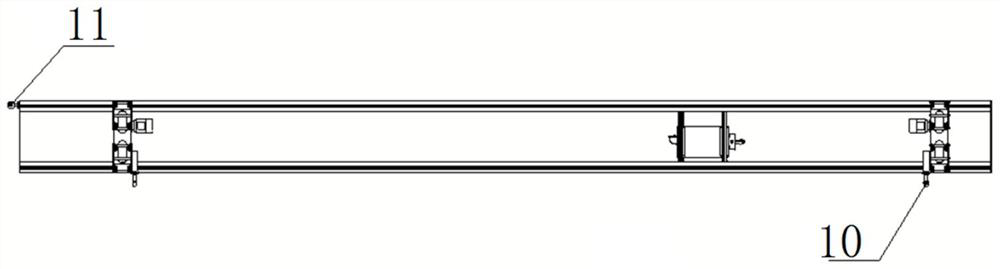

[0038] This embodiment provides an electric truss-type intelligent assembly workstation, and the motor drive assembly 6 is provided with a proximity sensor 10 . The electric truss-type intelligent assembly workstation also includes an alarm device, which is electrically connected to the proximity sensor 10 and emits an alarm sound when the electric truss-type intelligent assembly workstation moves to remind operators to pay attention to safety. The alarm device includes a horn arranged on the KBK suspension beam 1 and warning lights 11 arranged at both ends of the KBK suspension beam 1 . In addition, other alarm devices can also be added as required.

[0039] Below in conjunction with specific embodiment the present invention is described in detail, as Figure 4As shown, an electric truss-type intelligent assembly workstation, the motor drive assembly 6 is provided with a guide wheel, and the guide wheel is used in conjunction with the I-shaped track 8, so that the motor drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com