Straightening tool

A straightening and tooling technology, applied in feeding devices, manufacturing tools, positioning devices, etc., can solve the problems of low use efficiency, easy to break workpieces, and limited straightening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

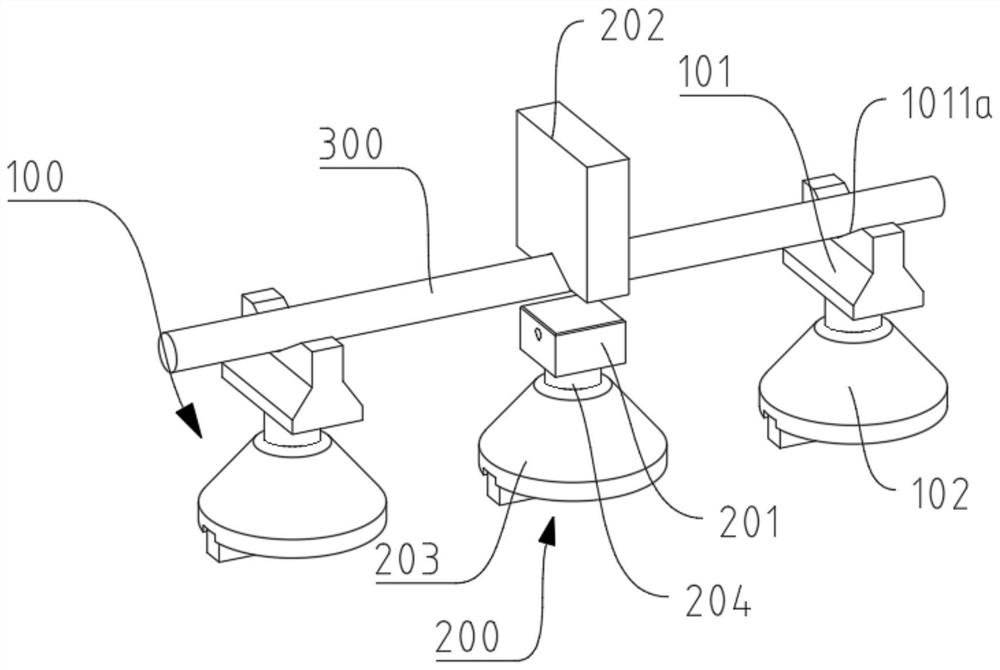

[0043] a kind of like figure 1 The straightening tool shown specifically includes:

[0044] The support assembly 100 used to clamp the two ends of the curved section of the workpiece 300 to be straightened, and the straightening assembly 200 for pressurizing and straightening the curved section of the workpiece 300 to be straightened, at least two support assemblies 100 are arranged symmetrically with the straightening assembly 200 as the center 1. At least one is installed on each side. After the erection of the straightening workpiece 300 is completed, the straightening assembly 200 is pressurized to straighten the curved section;

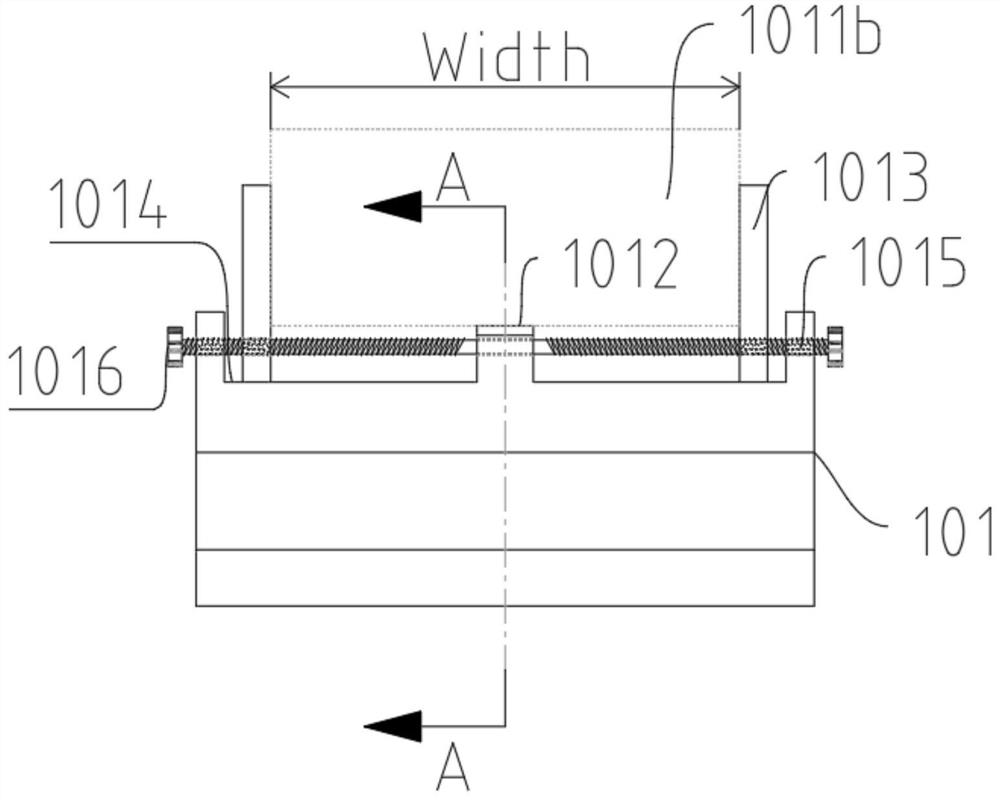

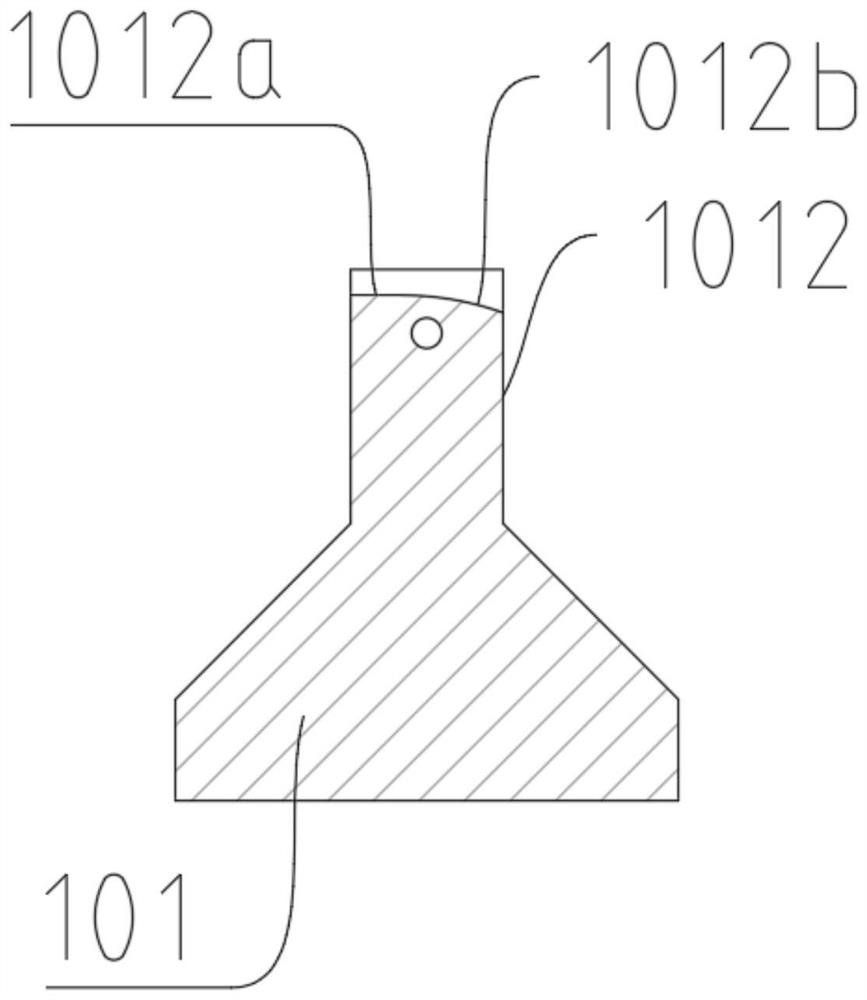

[0045] The support assembly 100 includes a support platform 101, the upper end surface of the support platform 101 is provided with a support notch 1011a for clamping the two ends of the curved section of the workpiece 300 to be straightened, the support notch 1011a opens upward, and the longitudinal section is V Shaped, V-shaped support notch 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com