Visual screening device for blasting beads

A screening device and visual technology, applied in the field of pop-bead visual screening device, can solve the problems of low efficiency, large number of labor, low accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

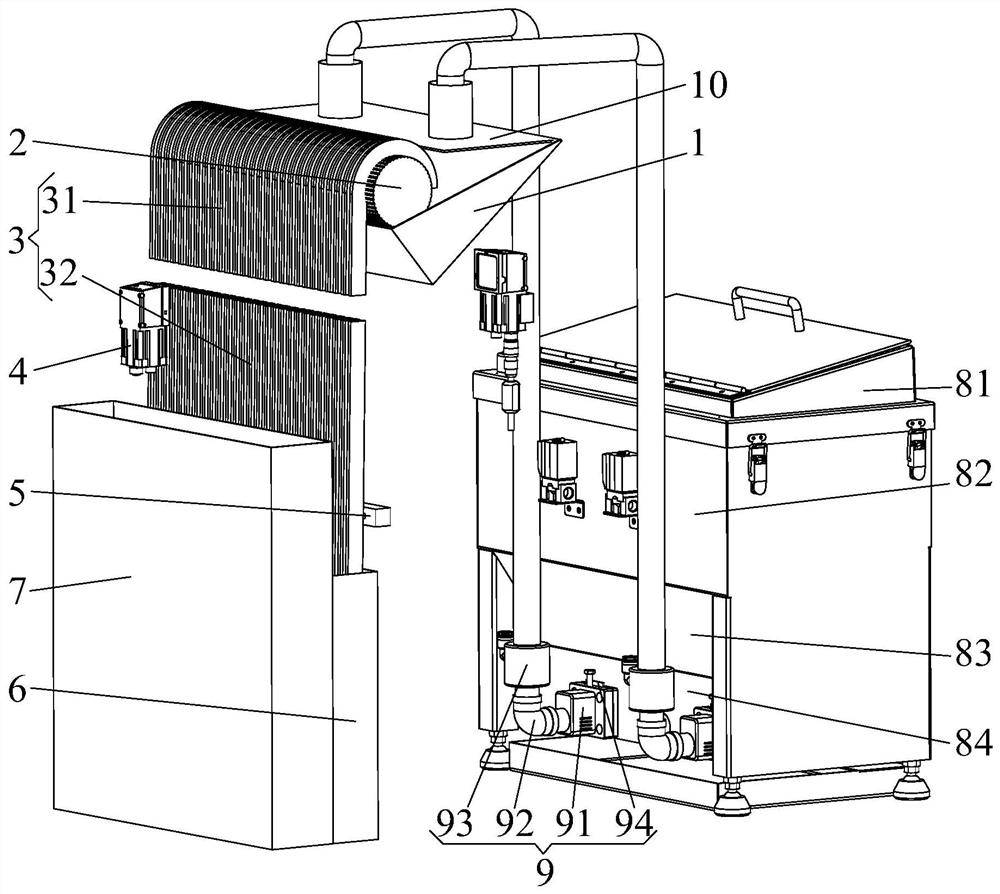

[0029] combine Figure 1 to Figure 3 As shown, a kind of blasting bead visual screening device disclosed in this embodiment includes a blocking bin 1, a discharge roller 2, a plurality of screening material partitions 3, two CCD detectors 4, a rejecting nozzle 5, a good product bin 6 and a secondary Product warehouse7. Wherein, the retaining bin 1 is fixedly installed according to the on-site use environment. The cross-section of the retaining bin 1 is triangular; the bottom of the triangle faces upwards, and the top corner faces downward, that is, the opening of the retaining bin 1 faces upwards, so that the explosive beads can be gathered at the bottom of the retaining bin 1 when the explosive beads are loaded. . Simultaneously, the discharge roller 2 of this embodiment is also installed according to the on-site environment. The discharge roller 2 is driven by a motor. The axial direction of the discharge roller 2 is parallel to the length direction of the blocking bin 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com