Heating non-combustion fuming particle mixture capable of avoiding caking

A heat-not-burn, smoking particle technology, applied in the fields of tobacco, food science, tobacco preparation, etc., can solve the problems of easy agglomeration, affecting the fluidity of tobacco particles, and adverse effects of heating uniformity of tobacco particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

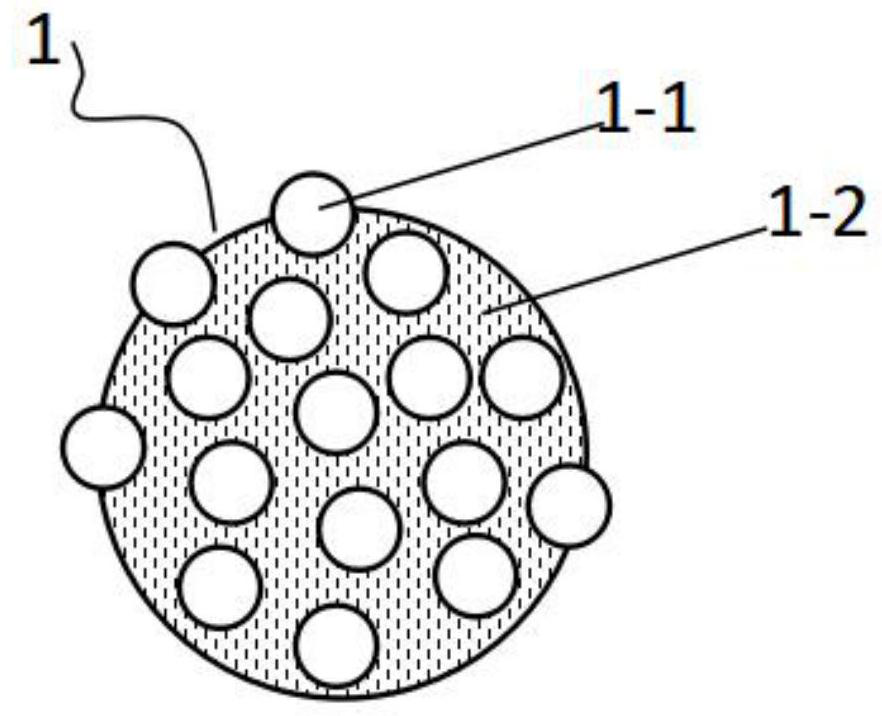

[0029] Mix tobacco powder, pectin, and water according to the mass ratio of 100:3:25, adopt the extrusion spheronization method to granulate, and then bake the spheronized tobacco granules in an oven at 90°C for 30-60 minutes. The granules passed through a 10-120 mesh sieve to obtain 10-120 mesh tobacco granules 1 without adding glycerin.

[0030] Wherein, the tobacco dust preparation method is as follows:

[0031] The local tobacco leaf raw material in Yunnan is ground into a powder with a particle size of 100-300 meshes to obtain the tobacco powder for later use.

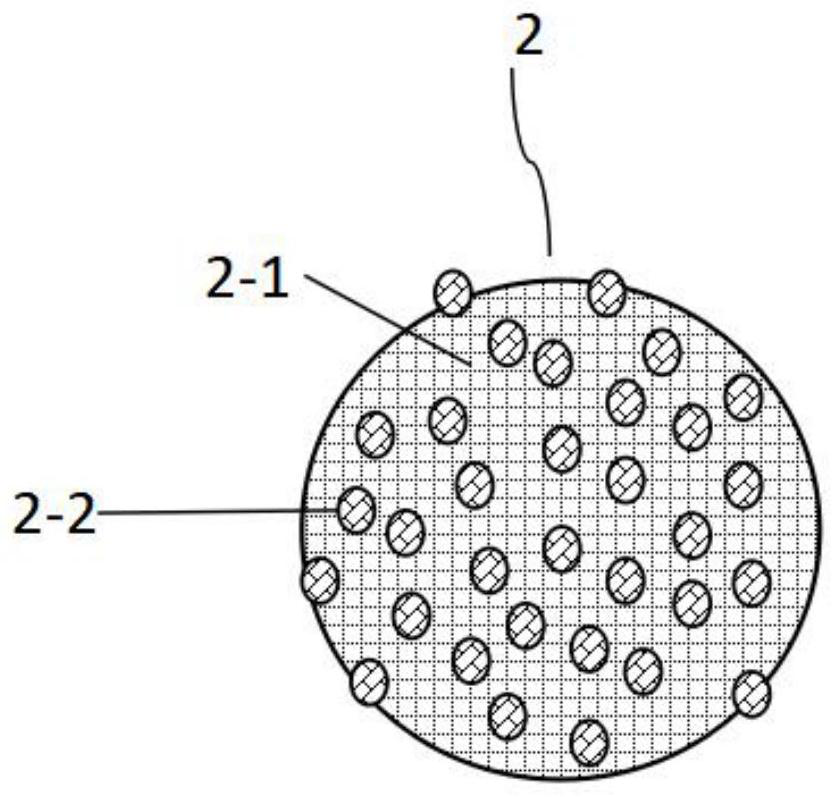

[0032] Smoker adsorption particles 2 are obtained by adsorbing glycerin on 10-120 mesh activated carbon particles. The above-mentioned tobacco particles 1 and smoker adsorption particles 2 are fully mixed according to a desired ratio to obtain the agglomeration-avoiding heat-not-burn smoke particle mixture of the present invention. in, figure 2 It is a schematic diagram of the structure of the tobacco particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com