Alternating current motor heat dissipation protection device

A technology for protecting equipment and AC motors. It is applied in electrical components, electromechanical devices, and electric components. It can solve problems such as poor motor protection capability, and achieve the effects of improving heat dissipation efficiency, increasing displacement, and increasing pumping volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

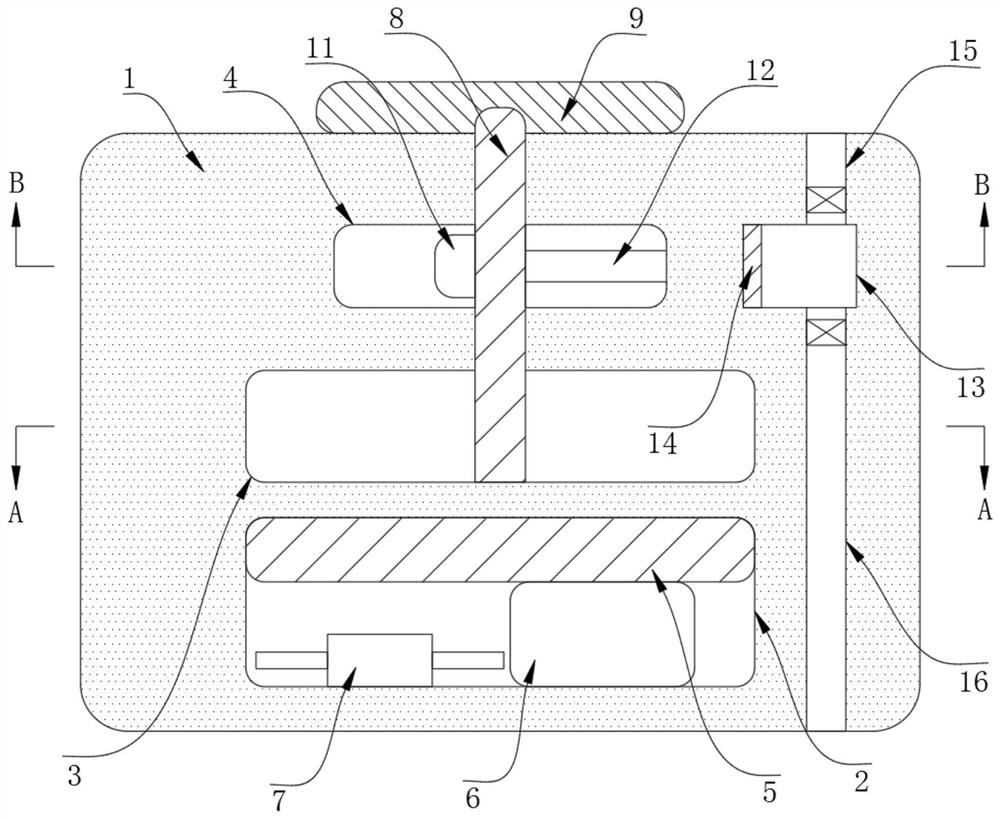

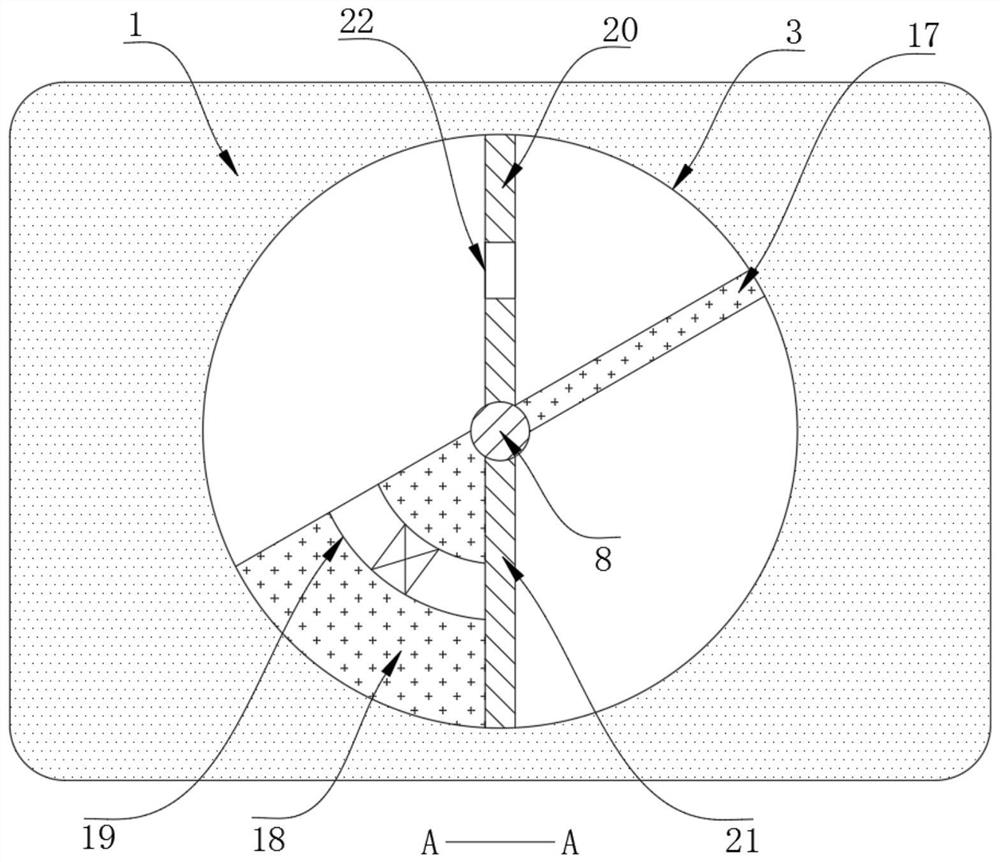

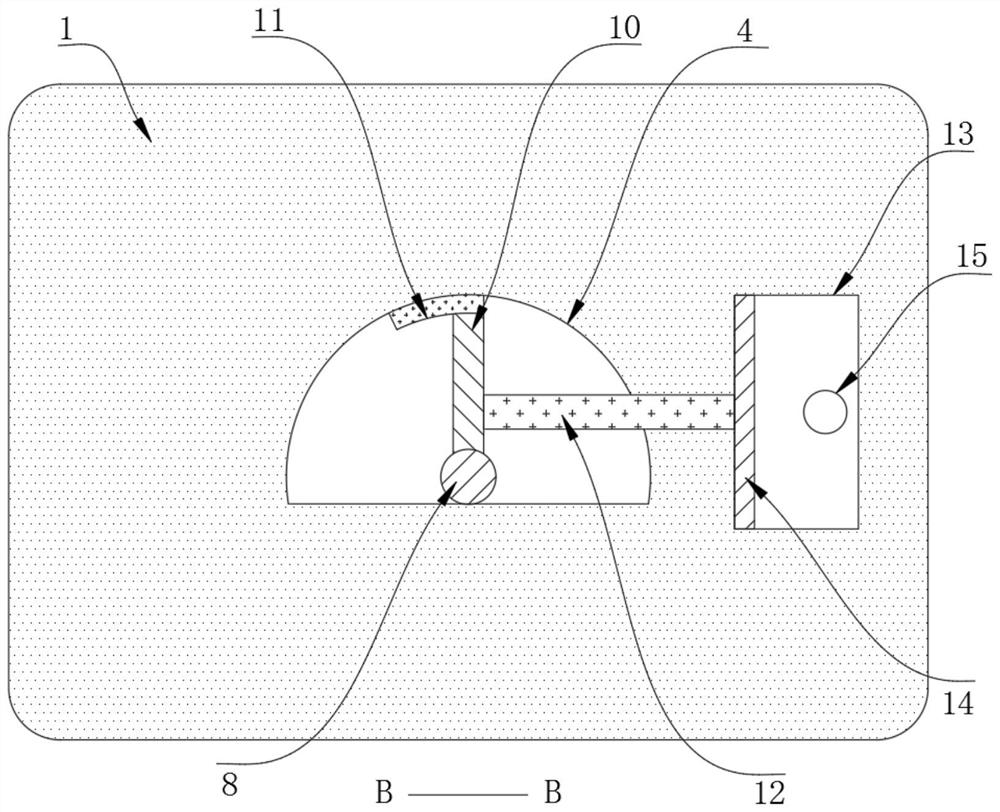

[0021] refer to Figure 1-3 , a heat dissipation protection device for an AC motor, comprising a casing 1, an element cavity 2, a buffer cavity 3 and an electric coupling cavity 4 are opened inside the casing 1, and a distribution resistor 5, an electromagnet 6 and a diode 7 are fixed inside the element cavity 2, The distribution resistor 5 is connected in parallel with the electromagnet 6, and the diode 7 is used to limit the current passing through the electromagnet 6, so that the electromagnet 6 generates a magnetic field intermittently. The inner wall of the buffer chamber 3 is connected with a rotating shaft 8 through a torsion spring, and the rotating shaft 8 runs through the buffer chamber 3 and the electrical union chamber 4 extend to the outside of the housing 1 and are fixed with a rotating plate 9. A slow release mechanism is provided inside the buffer chamber 3, and a rotating plate 9 is fixed on the circumferential side wall of the rotating shaft 8 located inside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com