Simulation method and device applied to industrial detection, equipment and storage medium

A simulation method and industrial technology, applied in design optimization/simulation, special data processing applications, electrical components, etc., can solve problems such as long debugging time and inability to obtain images in real time, so as to ensure smooth links, avoid mutual interference, and avoid The effect of image data transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

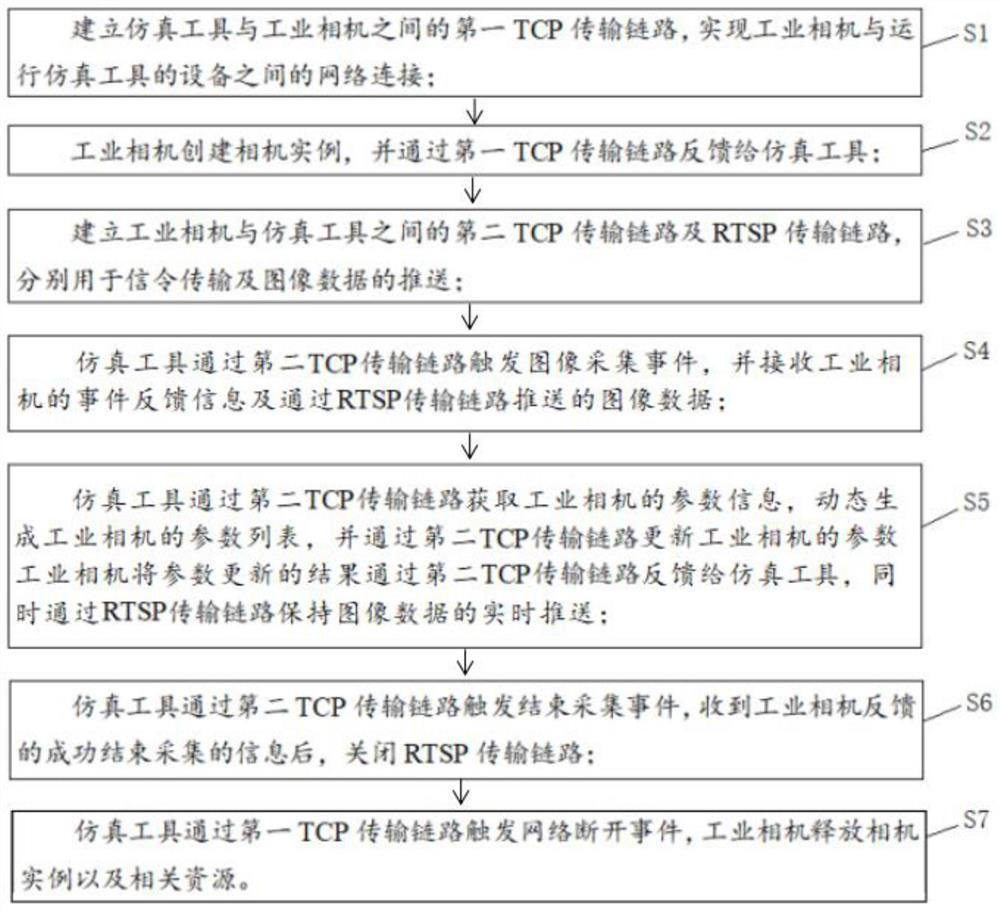

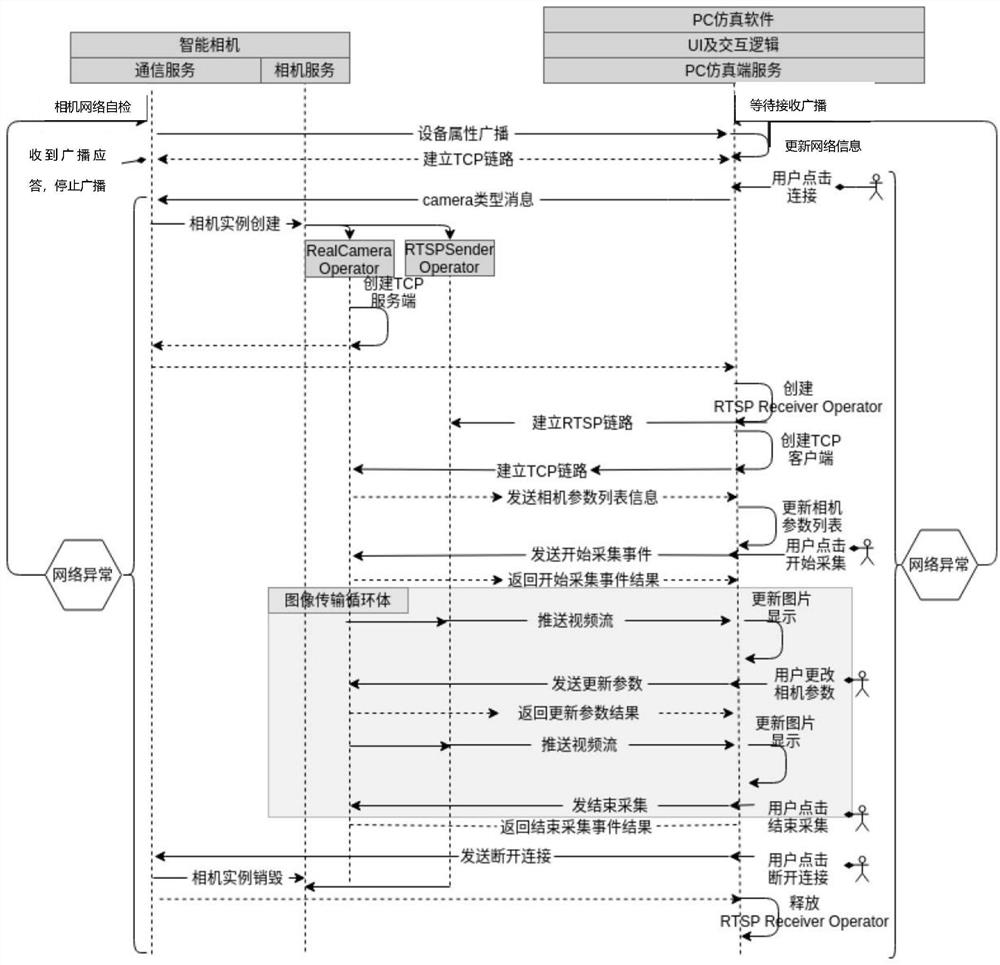

[0041] Please see figure 1 , the simulation method applied to industrial detection provided by this embodiment includes:

[0042] Step S1: establish the first TCP transmission link between the simulation tool and the industrial camera, and realize the network connection between the industrial camera and the equipment running the simulation tool;

[0043] Step S2: the industrial camera creates a camera instance, and feeds back to the simulation tool through the first TCP transmission link;

[0044] Step S3: establishing a second TCP transmission link and an RTSP transmission link between the industrial camera and the simulation tool, which are respectively used for signaling transmission and image data push;

[0045] Step S4: The simulation tool triggers the image acquisition event through the second TCP transmission link, and receives the event feedback information of the industrial camera and the image data pushed through the RTSP transmission link;

[0046] Step S5: The simu...

Embodiment 2

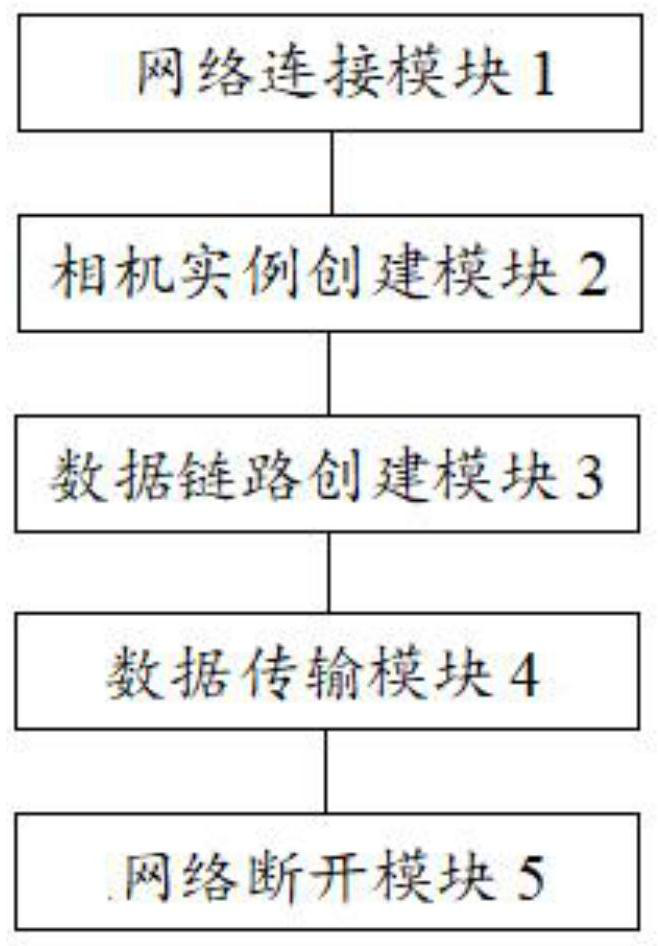

[0071] This embodiment provides a simulation device applied to industrial testing, please refer to image 3 , the simulation setup consists of:

[0072] The network connection module 1 is used to establish the first TCP transmission link between the simulation tool and the industrial camera, so as to realize the network connection between the industrial camera and the equipment running the simulation tool;

[0073] The camera instance creation module 2 is used to create a camera instance for the industrial camera and feed it back to the simulation tool through the first TCP transmission link;

[0074] The data link creation module 3 is used to establish a second TCP transmission link and an RTSP transmission link between the industrial camera and the simulation tool, which are respectively used for signaling transmission and image data push;

[0075] The data transmission module 4 is used to realize that the simulation tool triggers the image acquisition event through the sec...

Embodiment 3

[0079] The above-mentioned second embodiment describes the simulation device applied to industrial inspection of the present invention from the perspective of modularized functional entities. The simulation device applied to industrial detection of the present invention is described in detail below from the perspective of hardware processing.

[0080] Please see Figure 4 , the simulation device 500 applied to industrial detection may have relatively large differences due to different configurations or performances, and may include one or more processors (central processing units, CPU) 510 (for example, one or more processors) and Storage 520, one or more storage media 530 (such as one or more mass storage devices) for storing application programs 533 or data 532 . Wherein, the memory 520 and the storage medium 530 may be temporary storage or persistent storage. The program stored in the storage medium 530 may include one or more modules (not shown in the figure), and each mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com