Lining formwork trolley for open-cut rectangular tunnel

A formwork trolley and rectangular technology, which is applied in tunnel lining, tunnel, shaft lining and other directions, can solve the problems of affecting the personal safety of the staff, welding slag falling below the trolley, and the lack of welding slag collection function, etc., to achieve The effect of reducing labor intensity, convenient storage, and reducing the time for installation and reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

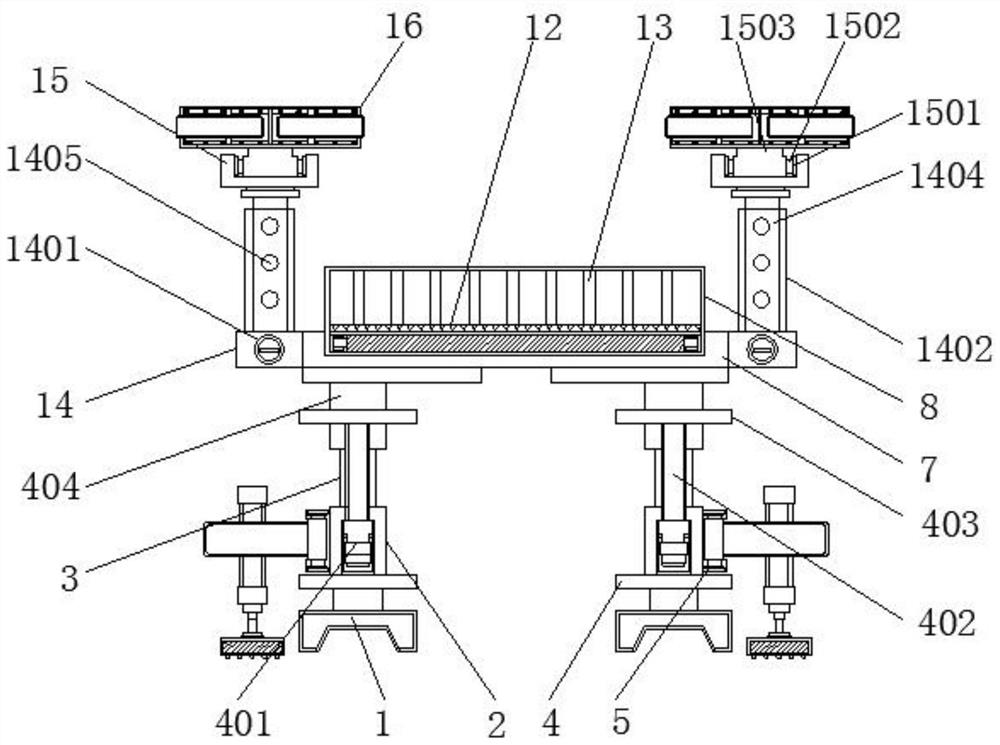

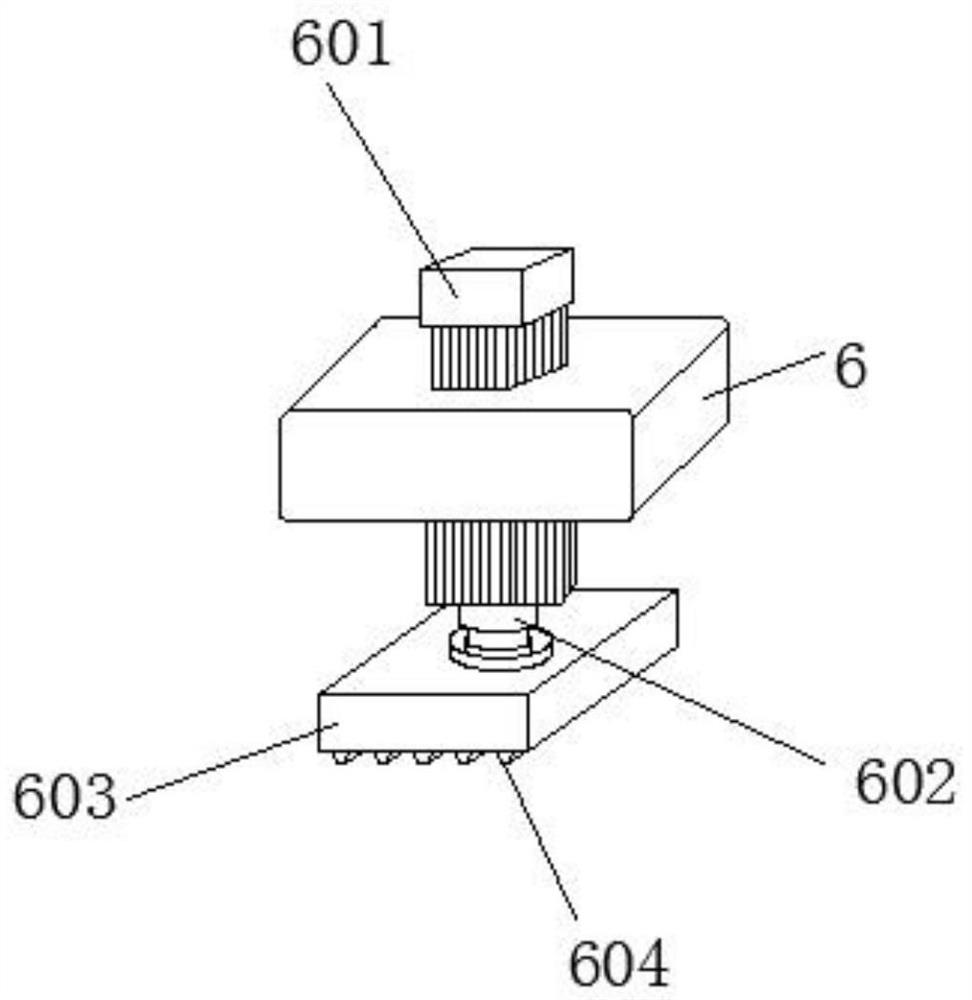

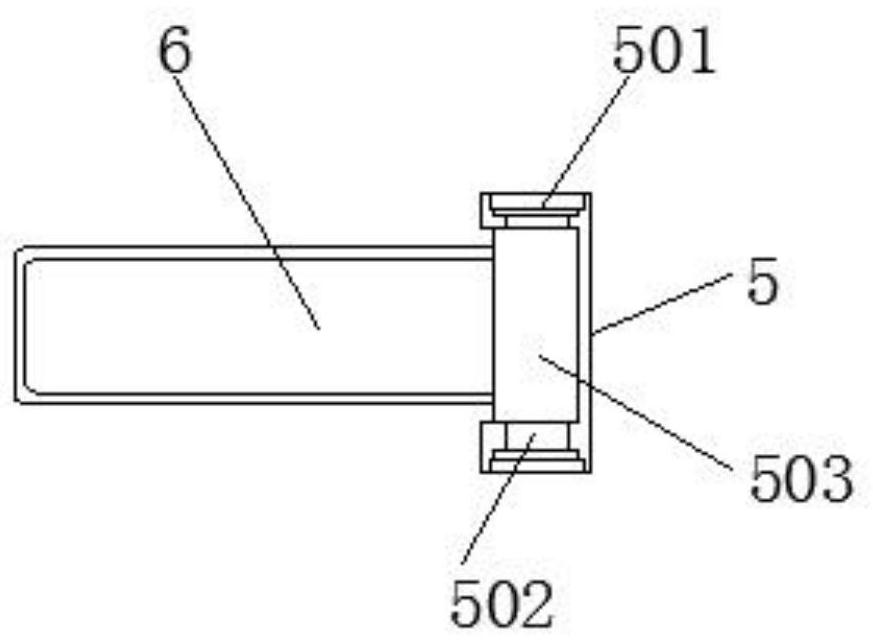

[0030] see Figure 1-6 , in this embodiment: a lining formwork trolley for open-cut rectangular tunnels, including an underframe 1, an installation frame 2 is arranged above the outer side of the underframe 1, and a support frame 3 is connected to the outer side wall of the installation frame 2 to support The outer top of frame 3 is provided with elevating mechanism 4, and the outside of support frame 3 is provided with rotating mechanism 5, and the outer one end of rotating mechanism 5 is connected with reinforcing mechanism 6, and the outer top of elevating mechanism 4 is provided with placing frame 7, and placing frame The outer front of 7 is provided with workbench 8, and the inner side wall of workbench 8 is all provided with first chute 9, and the inboard of first chute 9 is provided with first slide block 10, and first slide block 10 is connected with rubbish box simultaneously. 11 are connected, the inner side of the workbench 8 is provided with an anti-skid plate 12, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com