Split type gap bridge structure of suspension body coal mining machine and body of ultra-thin coal seam coal mining machine

An extremely thin coal seam and shearer technology, applied in the field of shearer body and shearer bridge structure, can solve the problem of affecting production, the bridge structure cannot meet the supporting requirements of conveyors with different widths, and increase equipment maintenance costs, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

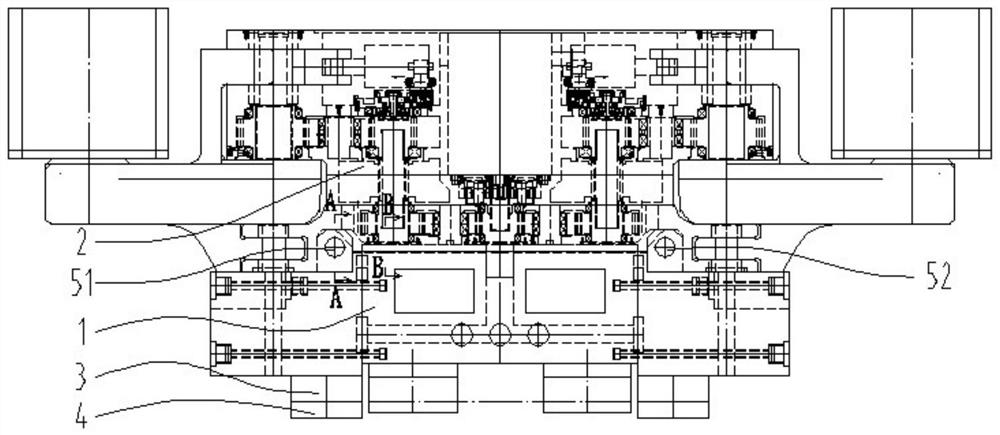

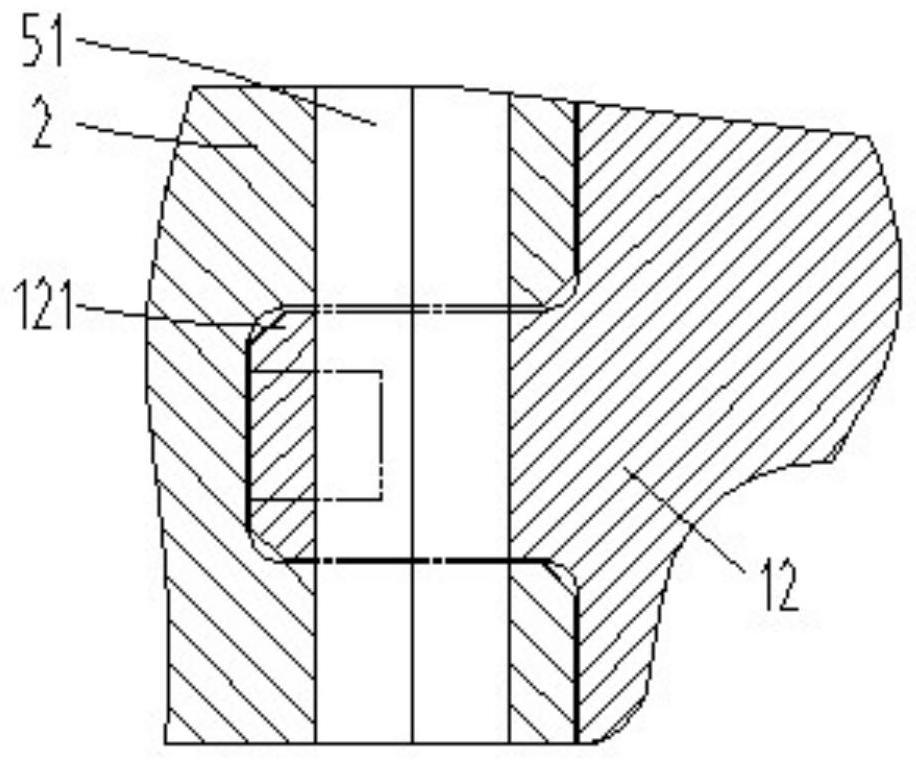

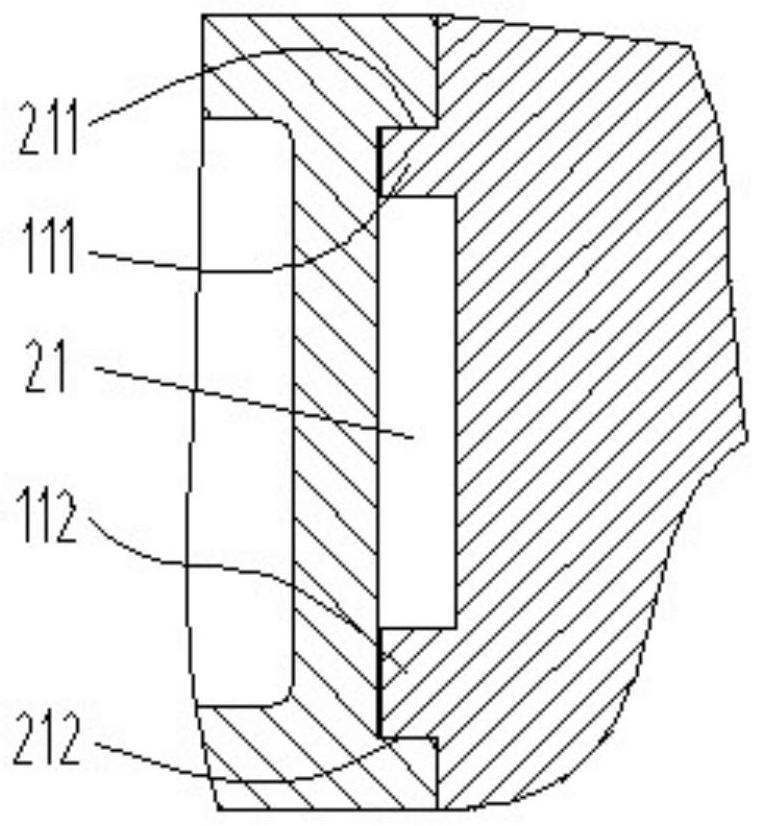

[0033] The invention discloses a split bridge structure 1 for a coal shearer with a suspended body, such as Figure 1-8 As shown, it includes a middle box body 11 and a left connecting block 12 and a right connecting block 13 respectively detachably fixed on the left and right sides of the middle box body, and the connection between the middle box body and the left connecting block and the right connecting block The positioning method can be through the vertical end faces that fit each other and one or more positioning pins that vertically pass through the two end faces that fit each other. The front end face of the middle box body is provided with an upper positioning boss 111 and a lower positioning boss 112 which are horizontally protruding and extend left and right. (For example, the left front part of the right connecting block) is respectively provided with a left connecting ear 121 and a right connecting ear 131 protruding horizontally forward, and the earholes on the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com