Preparation method for embedded composite fibers with excellent cooling and filtering effects and product

A composite fiber and embedded technology, which is applied to artificial filaments made of cellulose derivatives, fiber chemical characteristics, artificial silk manufacturing, etc., can solve the problems of increasing manufacturing difficulty, increasing manufacturing costs, and ineffective effects, etc., to achieve Reduce the difficulty of production, easy to operate, and not difficult to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

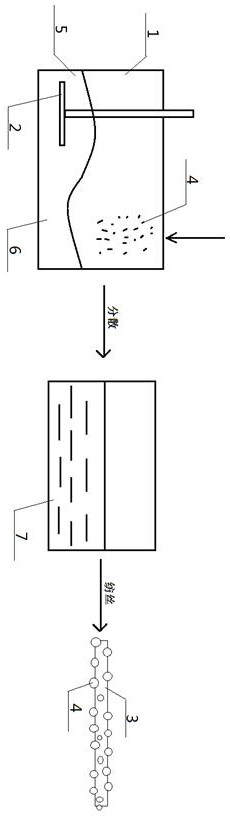

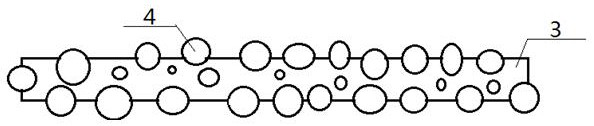

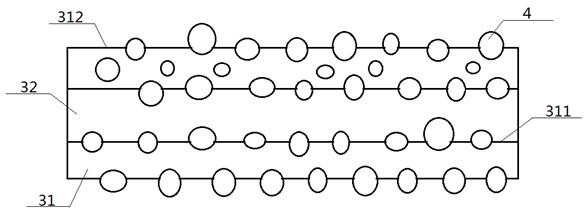

[0037] see figure 1 — image 3 , a kind of preparation method of embedded cooling filter double excellent composite fiber, described preparation method comprises the following steps:

[0038] PLA powder treatment: ball milling and dispersing the existing PLA powder 4 until the size of the PLA powder 4 is 50-500 mesh;

[0039] Mixing of powder and liquid: first make the base liquid 5 in a state of being stirred, then add the dispersed PLA powder 4 to the base liquid 5, and add it while stirring until all the PLA powder 4 is added to obtain a mixed solution 6, and then the primary mixed solution 6 is dispersed to obtain the secondary mixed solution 7;

[0040] Formation of composite fibers: first perform spinning operation on the above-mentioned secondary mixed liquid 7 to obtain initial fibers, the spinning operation is wet spinning or electrospinning or centrifugal spinning or combined use of electrospinning and centrifugal spinning, Then the initial fiber is passed through...

Embodiment 1

[0062] see figure 1 — image 3 , a kind of preparation method of embedded cooling filter double excellent composite fiber, described preparation method comprises the following steps:

[0063] PLA powder treatment: ball milling and dispersing the existing PLA powder 4 until the size of the PLA powder 4 is 50-500 mesh;

[0064] Mixing of powder and liquid: first make the base liquid 5 in a state of being stirred, then add the dispersed PLA powder 4 to the base liquid 5, and add it while stirring until all the PLA powder 4 is added to obtain a mixed solution 6, and then the primary mixed solution 6 is dispersed to obtain the secondary mixed solution 7;

[0065] Formation of composite fibers: first perform spinning operation on the above-mentioned secondary mixed liquid 7 to obtain initial fibers, the spinning operation is wet spinning or electrospinning or centrifugal spinning or combined use of electrospinning and centrifugal spinning, Then the initial fiber is passed through...

Embodiment 2

[0068] Basic content is the same as embodiment 1, the difference is:

[0069] The base liquid 5 is a diacetate spinning solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com