Acid pickling treatment tank for radiator processing

A radiator and treatment tank technology, applied in the field of pickling treatment tanks for radiator processing, can solve the problems of poor pickling effect, affecting the quality of pickling processing, uneven pickling of workpieces, etc., to improve the effect and improve pickling Processing quality and the effect of reducing the probability of internal air retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0040] see Figure 1-13 , the embodiment of the present invention provides a technical solution:

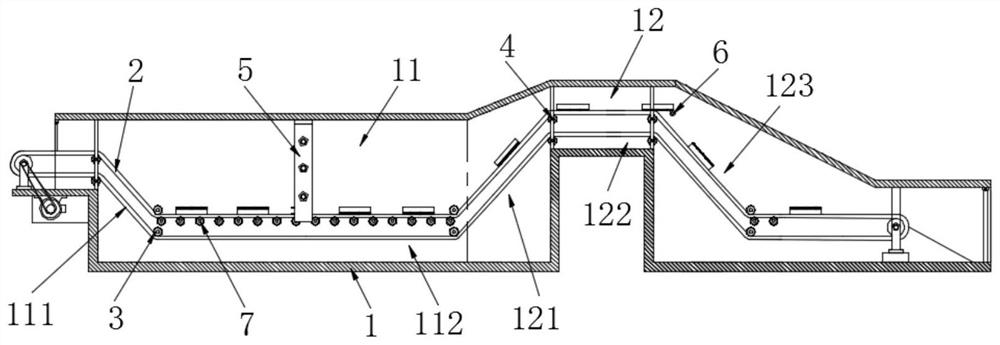

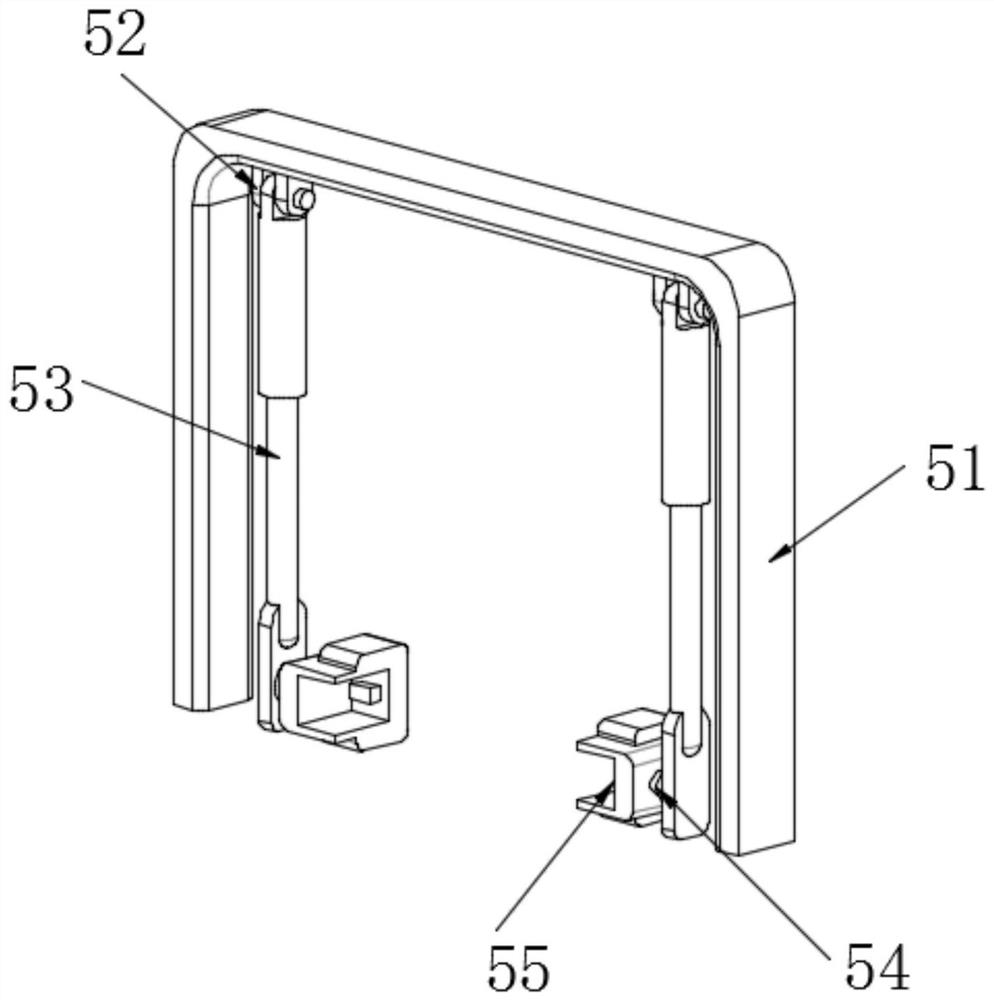

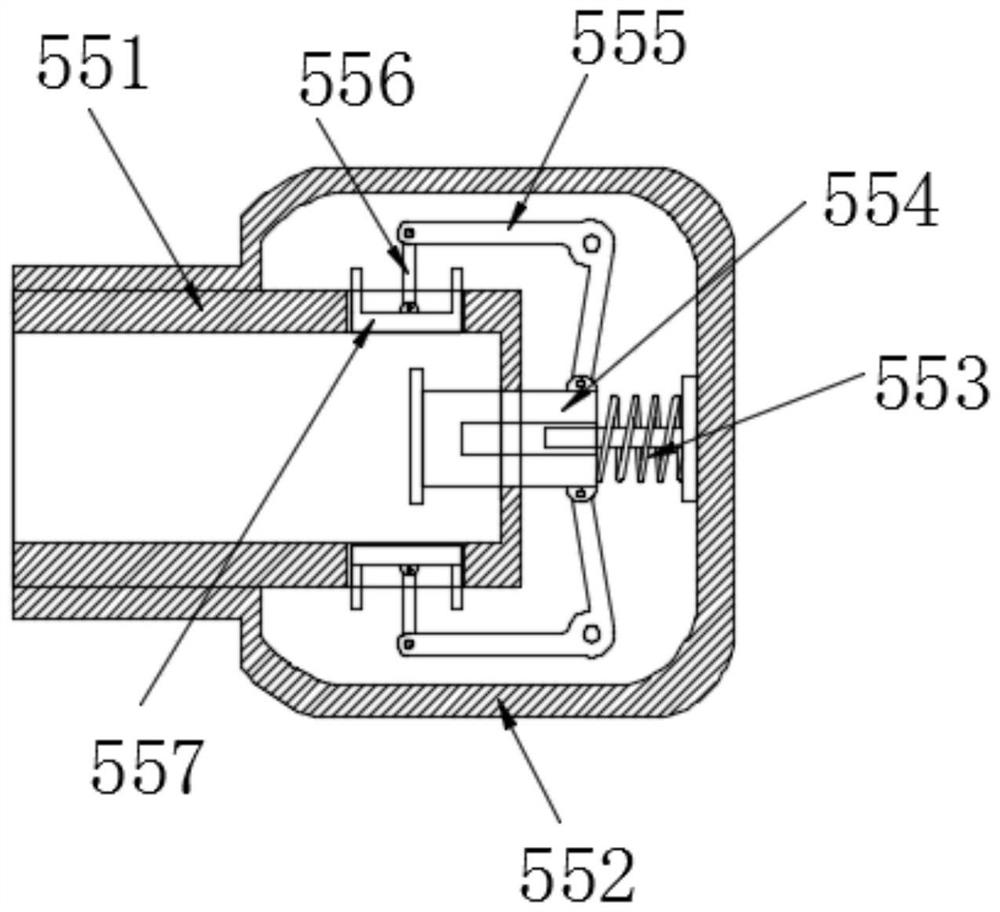

[0041]A pickling treatment tank for radiator processing, comprising a tank body 1 and a pickling turning mechanism 5; a conveyor belt 2 passes through the tank body 1, and a plurality of connecting mechanisms 23 are arranged on the conveyor belt 2 along its length direction to connect The mechanism 23 is used to limit the rotation of the forward tail end of the radiator; the inside of the tank body 1 is provided with a pickling chamber 11, and the pickling chamber 11 is provided with a horizontal pickling section 112 located inside the pickling solution. The washing and turning mechanism 5 is installed in the inside of the pickling bin 11 and is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com