Chemically toughened glass ion exchange tank

A chemical tempered glass and ion exchange technology, applied in the field of glass processing, can solve the problem that the contact point between the glass and the hanging cage cannot be effectively reacted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

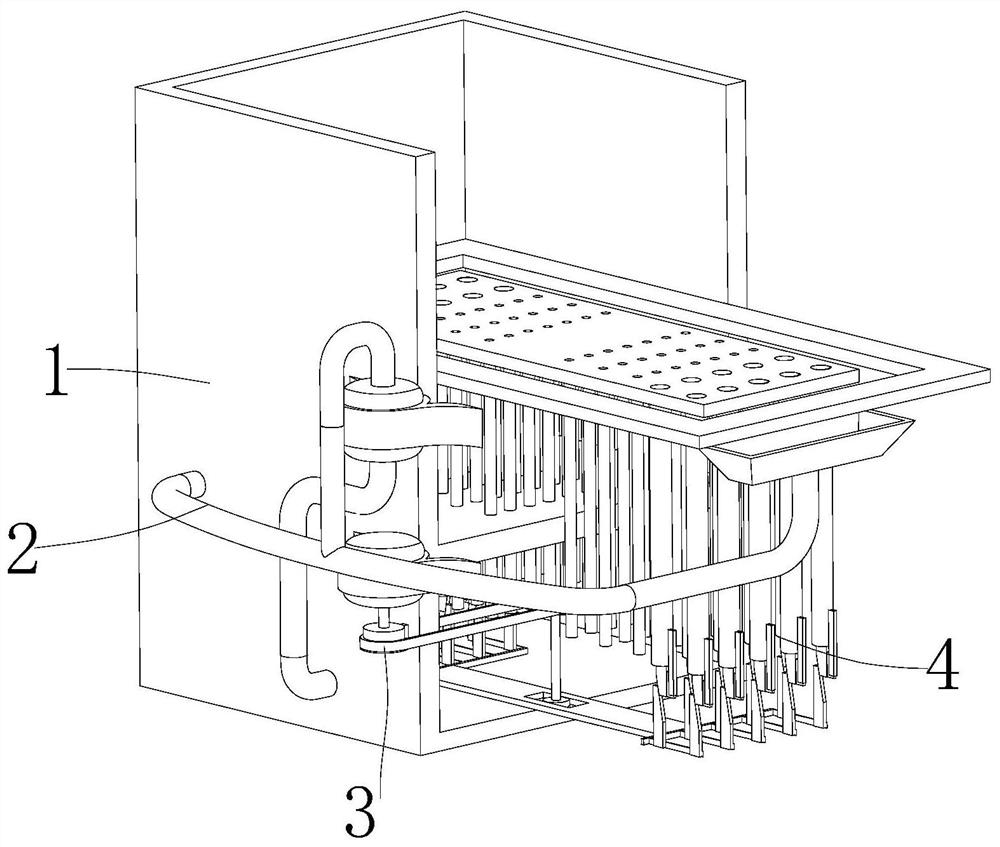

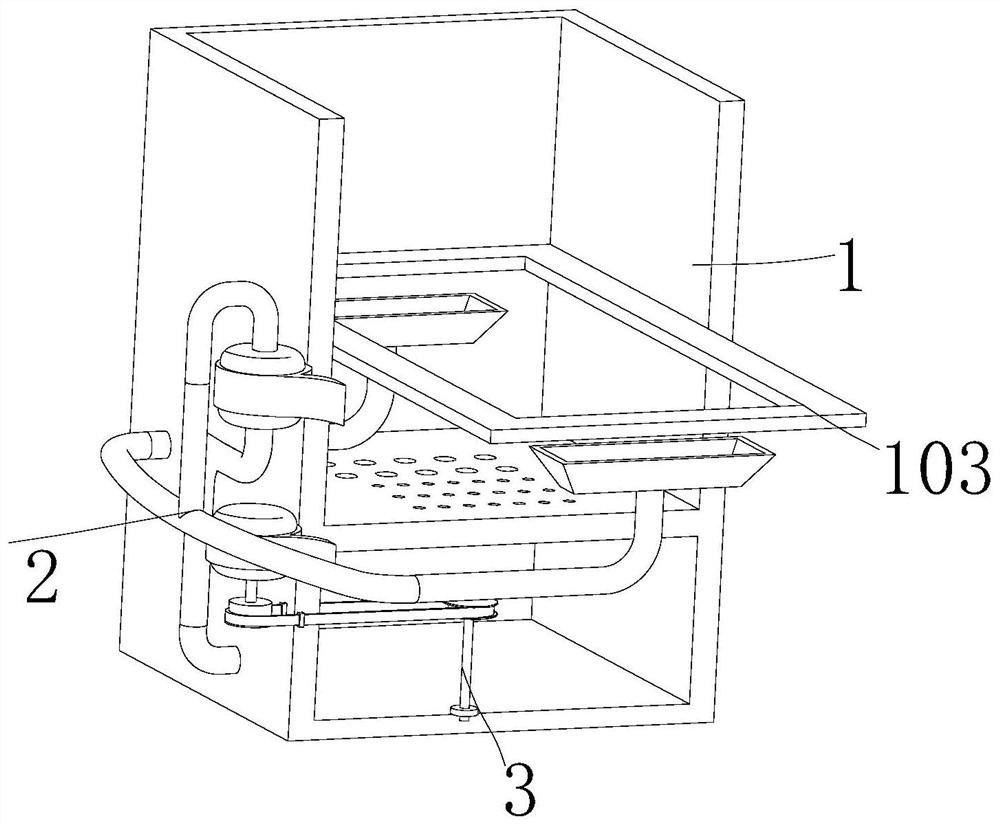

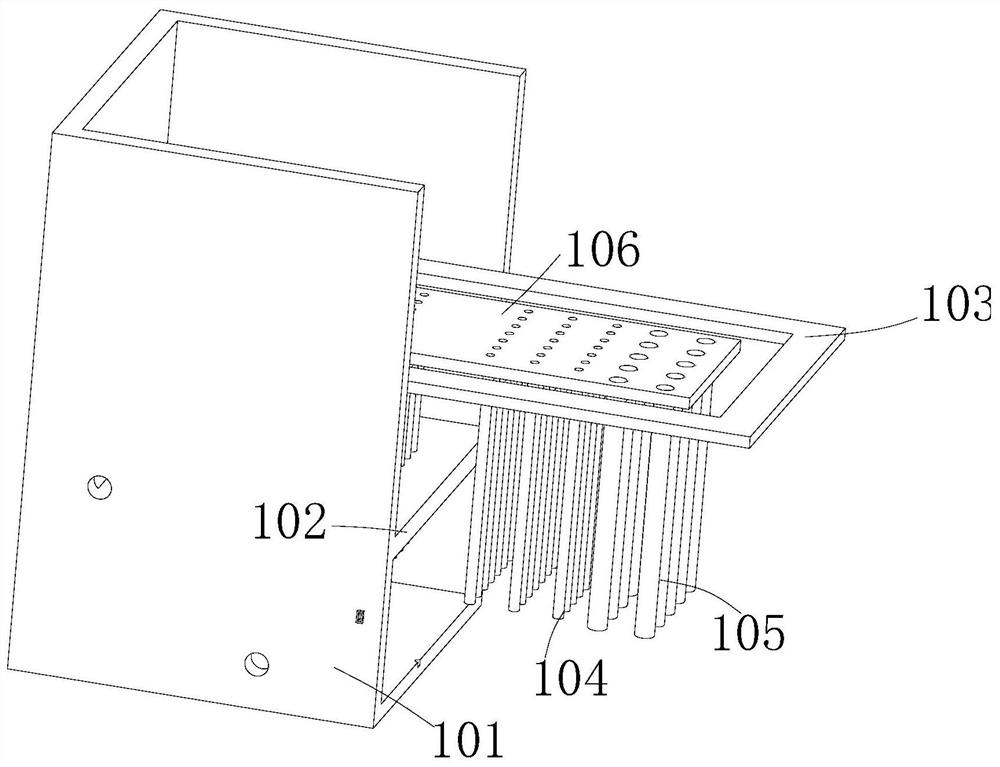

[0024] Embodiment one, such as Figure 1-6 As shown, it includes a tank body mechanism 1, a circulation mechanism 2 is fixedly installed above the front end of the tank body mechanism 1, the two ends of the circulation mechanism 2 are located inside the tank body mechanism 1, and the inner bottom wall of the tank body mechanism 1 is slidingly connected with an adjustment mechanism 3. The inside of the tank mechanism 1 is located on both sides of the adjustment mechanism 3, and the sliding mechanism 4 is fixedly installed. The sliding mechanism 4 and the adjustment mechanism 3 are clamped. The tank mechanism 1 includes a fixing groove 101, and the inside of the fixing groove 101 is fixed below A partition plate 102 is installed, and the partition plate 102 can divide the tank body into upper and lower parts. The inner wall of the fixed groove 101 is fixedly installed with a frame 103 above the partition plate 102, and the frame 103 plays a supporting role to the glass plate. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com