Sewage treatment sludge drying furnace

A technology of sludge drying and sewage treatment, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problem that the fried material board cannot be fried and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

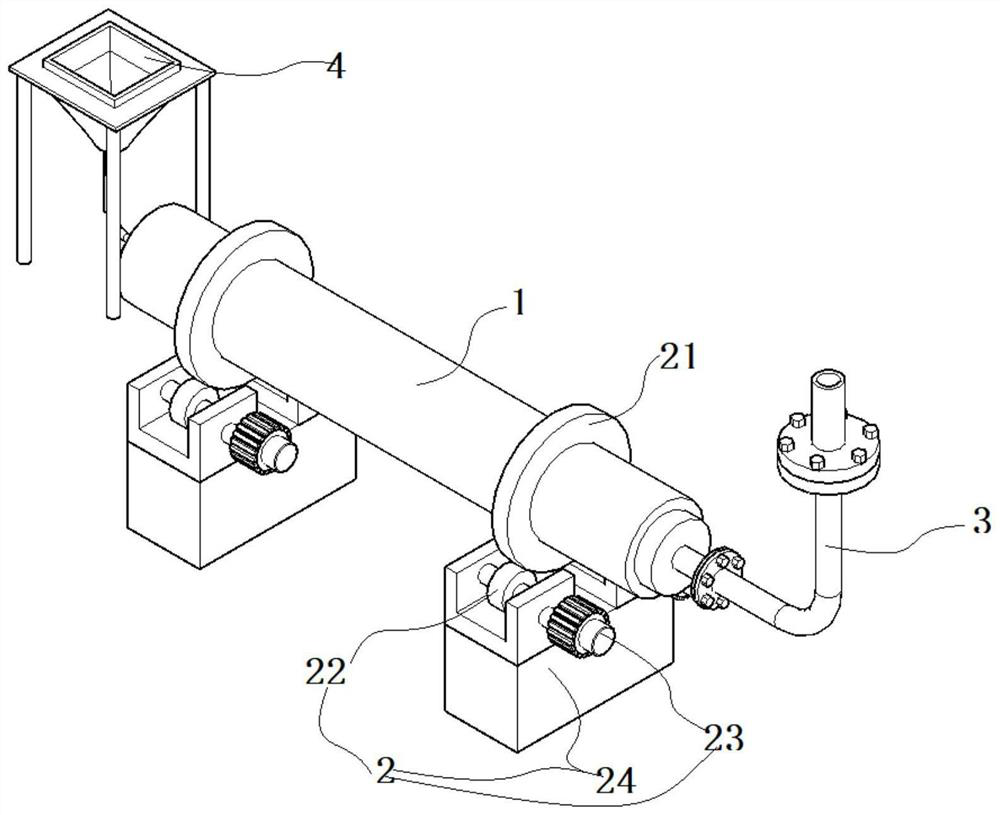

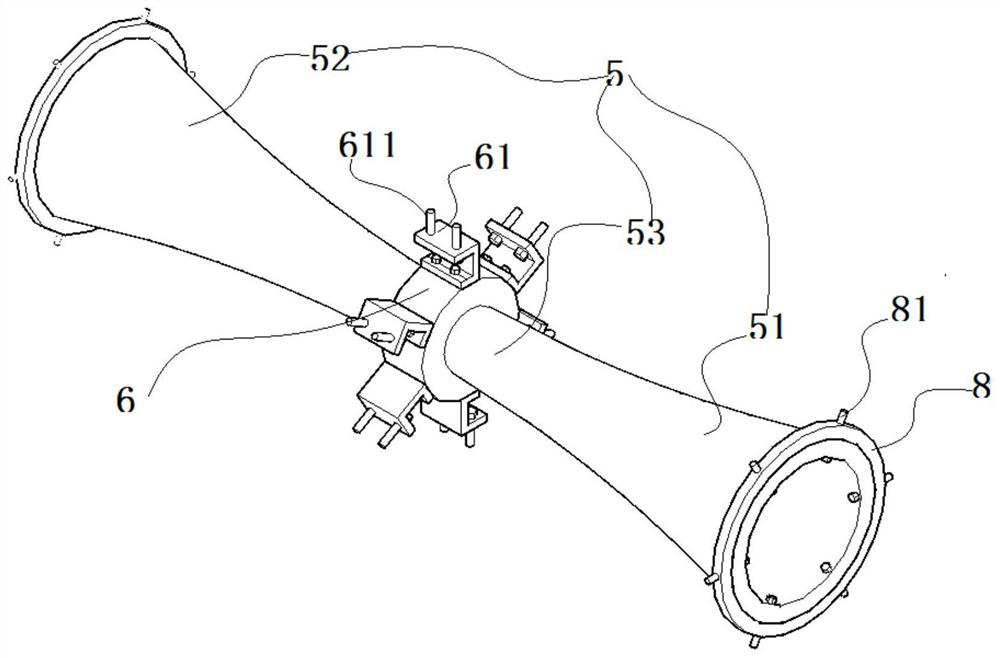

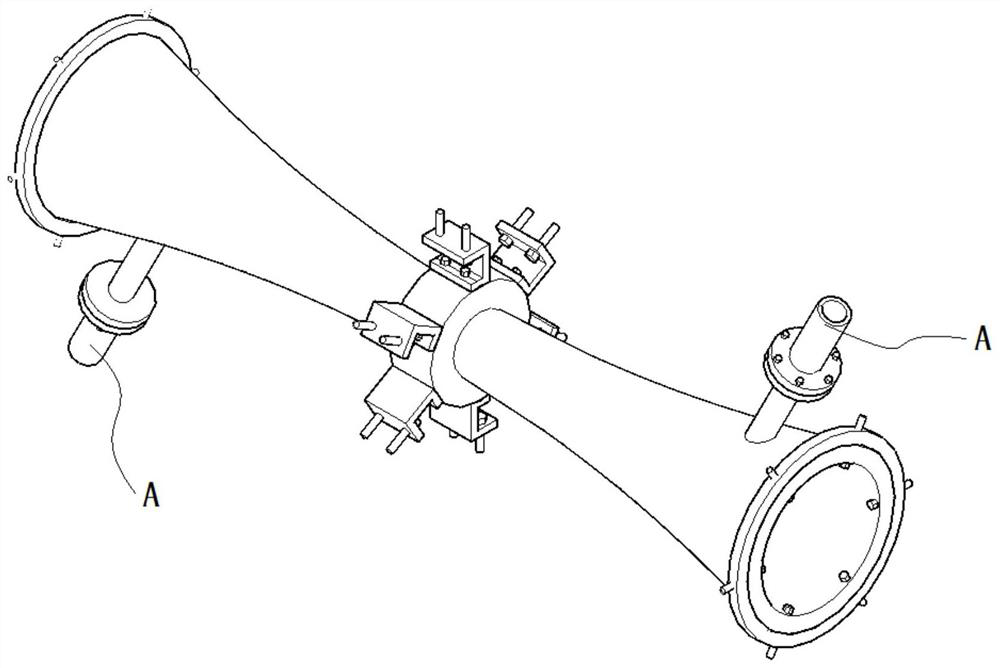

[0058] Such as Figure 1-9 As shown, a sewage treatment sludge drying furnace includes a drying furnace body, and the drying furnace body includes an outer furnace cylinder 1 and a trumpet-shaped inner furnace cylinder 5 assembled in the outer furnace cylinder 1 .

[0059] One of the improvement points of the present invention is to design the traditional cylindrical inner furnace drum into a trumpet-shaped inner furnace drum 5 .

[0060]Specifically, the shape of the trumpet-shaped inner furnace tube 5 includes a left tapered portion 52 and a right tapered portion 51 , and the left tapered portion 52 and the right tapered portion 51 . There is an intermediate portion 53 between the left tapered portion 52 and the right tapered portion 51 .

[0061] The radial lengths of the longitudinal cross-sectional shapes from the left tapered portion 52 to the middle portion 53 and from the middle portion 53 to the right tapered portion 51 decrease successively from large to small, whil...

Embodiment 2

[0088] Embodiment 2 pyrolysis efficiency comparative test

[0089] Such as Figure 10 As shown, the device disclosed in Example 1 of the present invention and the conventional drying furnace disclosed in the prior art are used to process the sludge produced by the same batch of sewage for drying operation. The processing pyrolysis efficiency curve of the present invention is as L1, and the existing The conventional drying furnace pyrolysis efficiency curve disclosed in the technology is L2.

[0090] From the data graphs of L1 and L2 processing, it can be seen that the device disclosed in the present invention has better efficiency in processing dried sludge. Among them, pyrolysis efficiency=qualified material / total amount of material, wherein, the qualified material is obtained through sieving, and is confirmed as a qualified product through physical and chemical characteristic testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com