Efficient loader sheet metal parts transfer device

A technology of transmission device and loader, which is applied in the direction of spraying device, conveyor, transportation and packaging, etc., and can solve problems such as shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

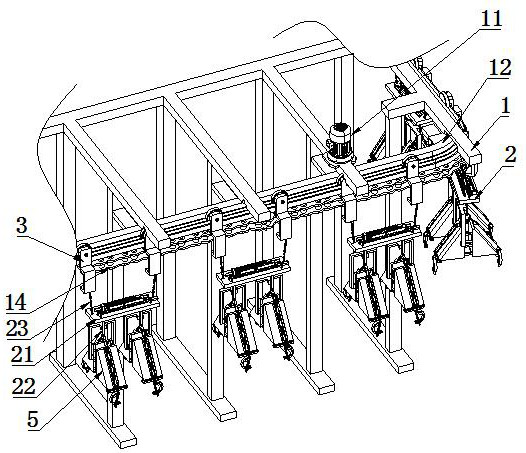

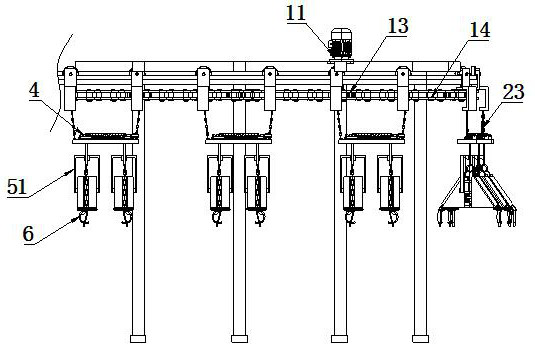

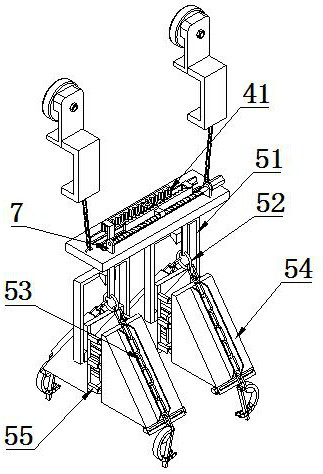

[0036] The present invention provides a kind of high-efficiency loader sheet metal transmission device here through improvement, as Figure 1-Figure 7 As shown, it includes a support frame 1, a driving motor 11 arranged on the top of the support frame 1, a conveying guide rail 12 arranged on the support frame 1, and a plurality of groups of sprockets 13 arranged on the support frame 1, between the plurality of groups of sprockets 13 The transmission chain 14 is tensioned, and the main shaft of the drive motor 11 is coaxially connected with one of the sprocket wheels 13. The present invention also includes multiple groups of suspension devices 2 and multiple groups of roller groups 3 that roll and cooperate with the conveying guide rail 12, and multiple groups of rollers The bottom of the group 3 is fixedly connected with the transmission chain 14, and each group of suspension devices 2 corresponds to two groups of roller groups 3 respectively, and the suspension device 2 is arr...

Embodiment 2

[0051]Based on the high-efficiency transmission device for sheet metal parts of a loader provided by the first embodiment of the present application, the second embodiment of the present application proposes another high-efficiency transmission device for sheet metal parts of a loader. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0052] The second embodiment of the present invention will be further described below in conjunction with the accompanying drawings and implementation methods.

[0053] refer to Figure 5 , Figure 7 As shown, specifically, in order to solve the problem that the paint sprayed by the disk on the side of the guide box 54 drips onto the surface of the sheet metal, the bottom of the guide box 54 is provided with a laterally arranged deflector 57, and its side wall is provided with a deflector. flow groove 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com