A transport moisture-proof frame for the wet agglomeration of recycled plastic particles in transport

A technology for recycling plastic particles and moisture, which is used in the field of plastic product production and processing equipment to prevent moisture agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

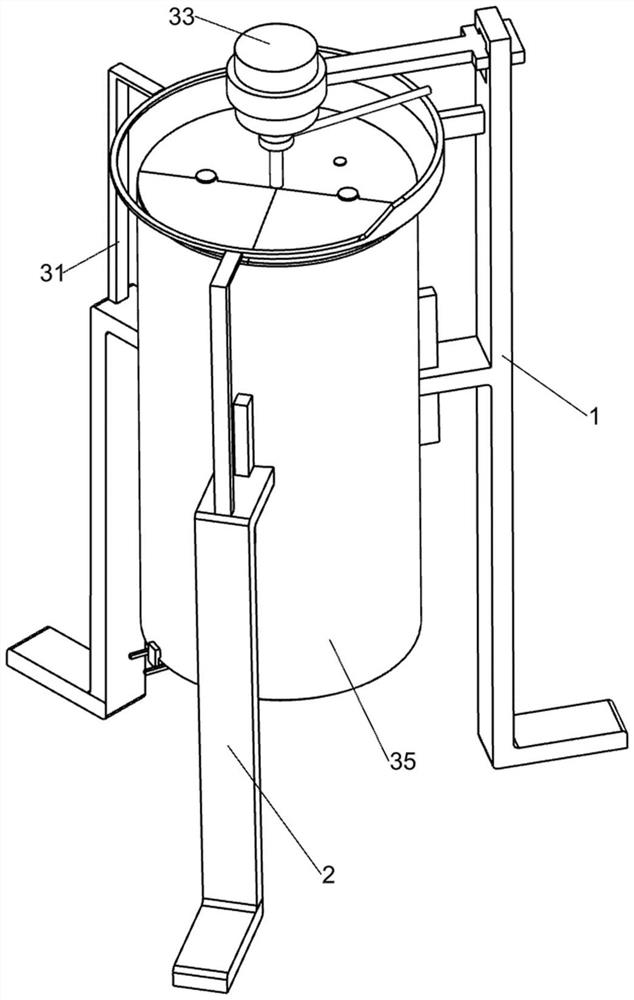

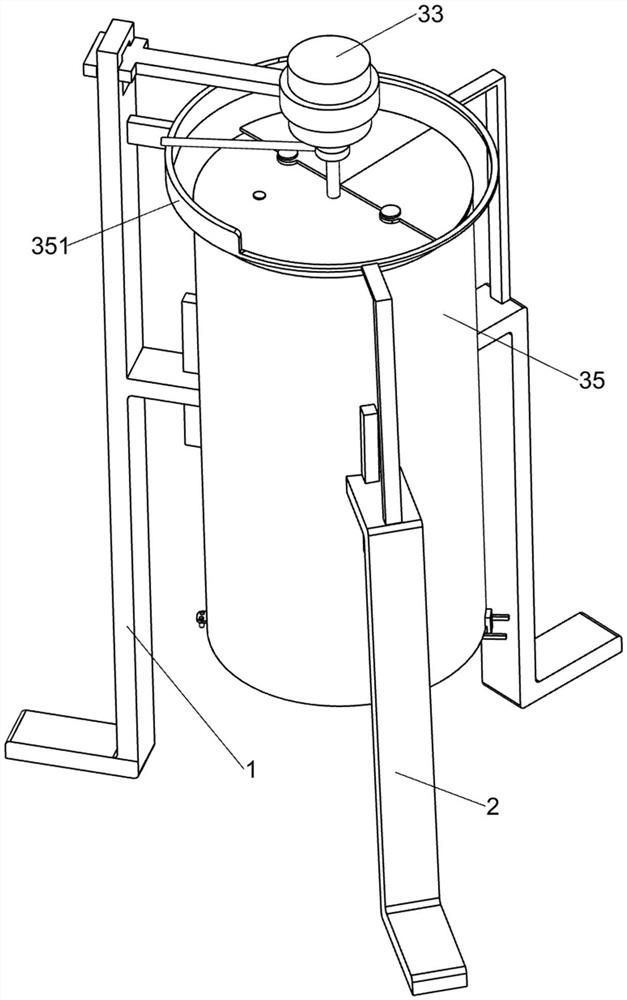

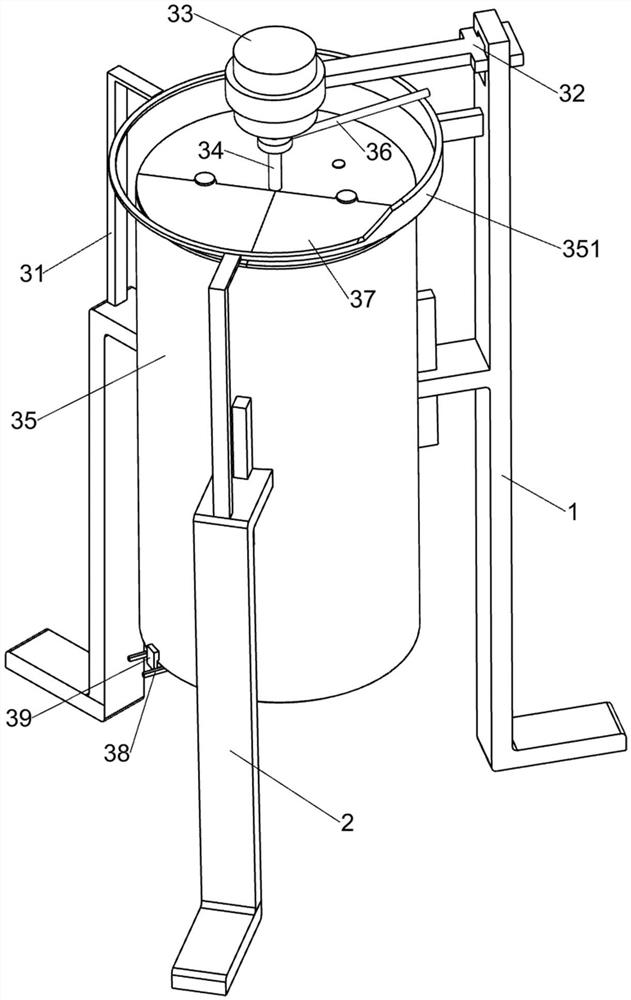

[0022] A transport moisture-proof frame for the wet agglomeration of recycled plastic particles in transport, such as Figure 1-6 As shown, it includes a support frame 1, a support leg frame 2, a shaking assembly 3, an oblique rotation assembly 4, an external rotation assembly 5, and a rotary rising assembly 6. The support frame 1 and the two support legs 2 are jointly slidably connected with a The shaking assembly 3, the shaking assembly 3 is used to shake the recycled plastic particles up and down, so that the recycled plastic particles will not stick together, the oblique rotating assembly 4 is fixed on the shaking assembly 3, and the outer rotating assembly 5 is arranged on the shaking assembly 3. On the upper side, the rotating rising component 6 is arranged on the inclined rotating component 4. The rotating rising component 6 is used to stir the recycled plastic particles to prevent the recycled plastic particles from being wet and agglomerated. The oblique rotating compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com