Medical paper-plastic bag with high bacterial resistance

A high-bacteria-resistant, paper-plastic bag technology, applied in the field of medical paper-plastic bags, can solve the problems of cost waste, unfavorable reuse, poor antibacterial effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

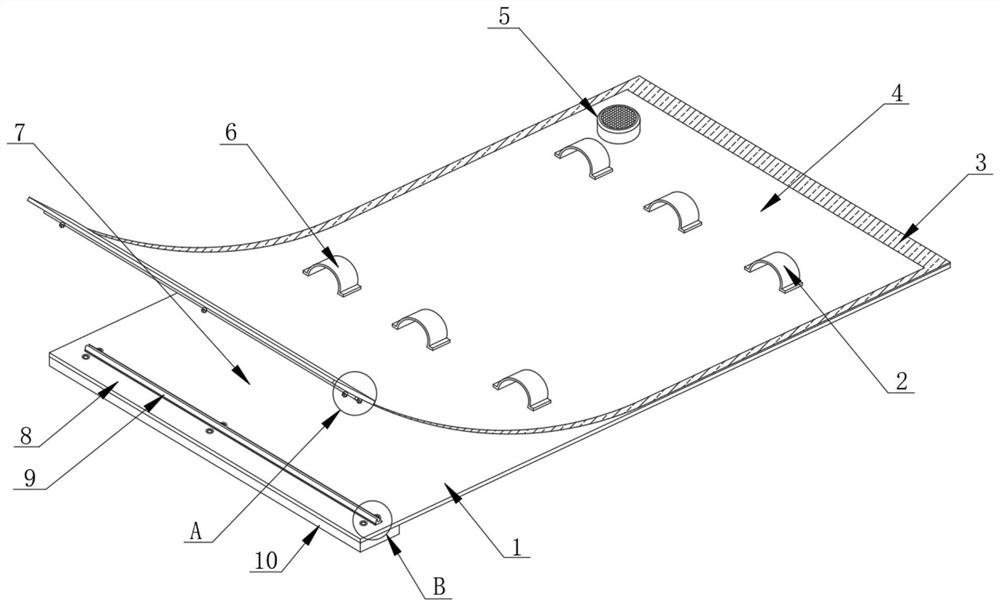

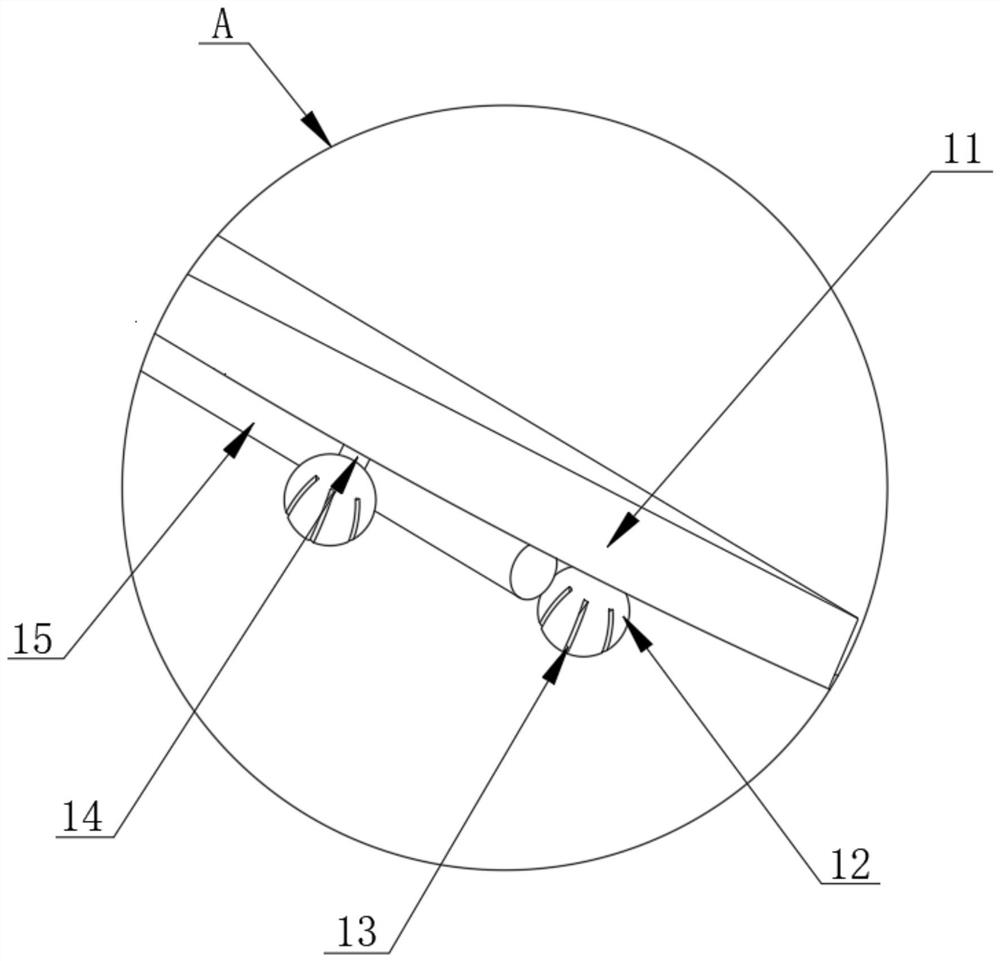

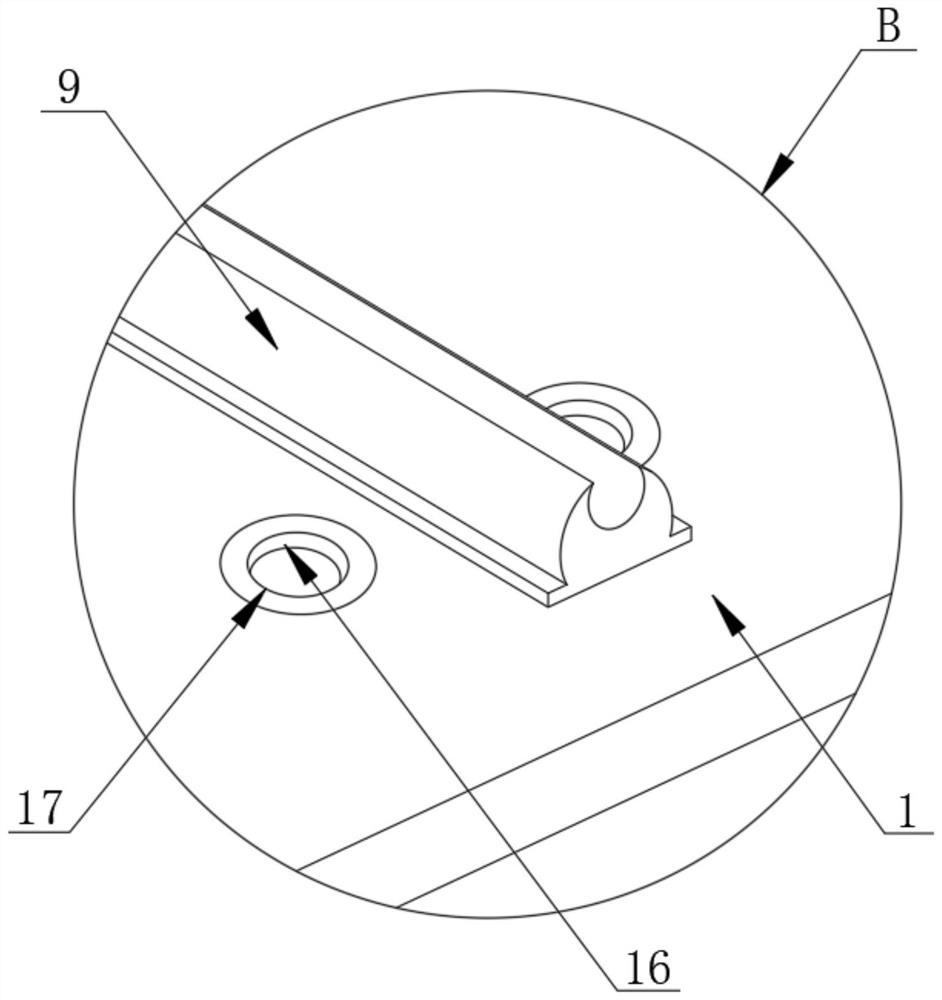

[0021] see Figure 1~5 , in an embodiment of the present invention, a medical paper-plastic bag with high resistance to bacteria includes a first surface layer 1, the first surface layer 1 is a composite material coated with polyethylene on the surface of kraft paper by a casting machine, the first surface layer The top of the layer 1 is provided with a second surface layer 4, the second surface layer 4 includes a base layer 42, the inside of the base layer 42 is bonded with a PP layer 41, and the outside of the base layer 42 is bonded with a toughening layer 44, the toughening layer 44 The antibacterial layer 43 is attached on the outside, and the antibacterial layer 43 adopts a silver-loaded antibacterial film, and the thickness of the antibacterial layer 43 is 2 μm, which has high antibacterial performance, reduces bacterial adsorption, and avoids hand contamination after contact with hands The problem of ensuring the sterility of the surgery.

[0022] The three sides conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com