Annular alignment device and rapid alignment method for coaxial butt joint of steel pipes

A ring and steel pipe technology, which is applied in the field of fast alignment and ring alignment devices, can solve problems such as difficulty in leveling the weld seam at the ring mouth, weld seam staggered welding, etc., to save machinery and labor costs, ensure welding quality, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale.

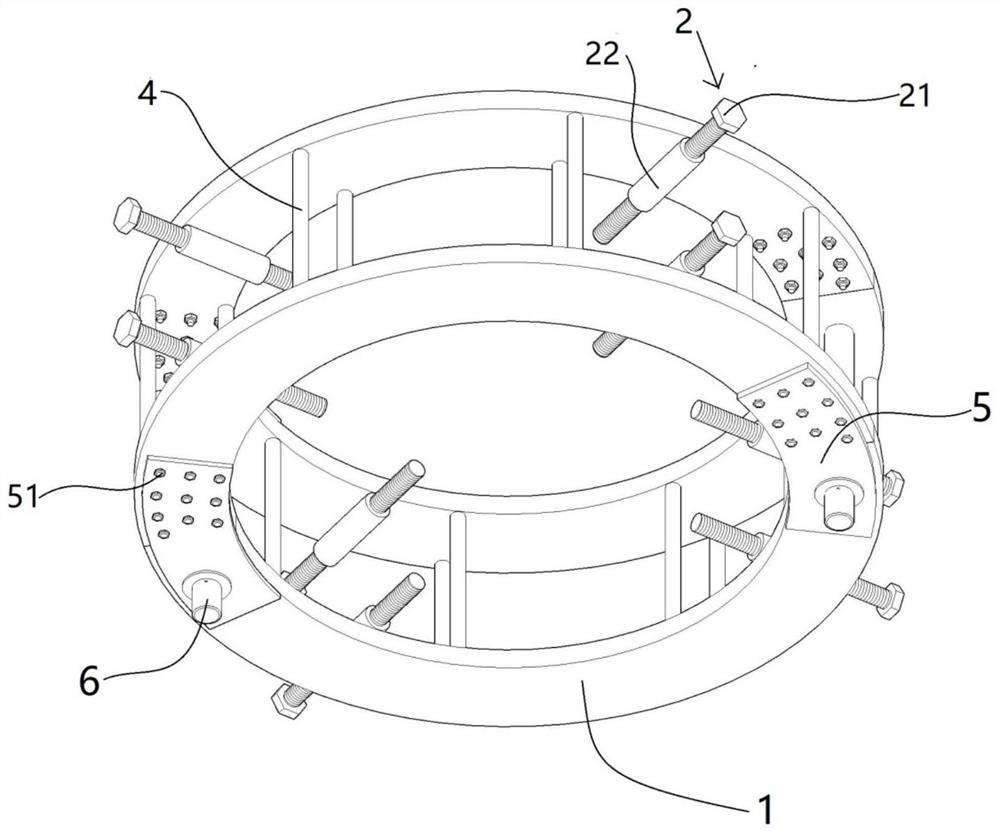

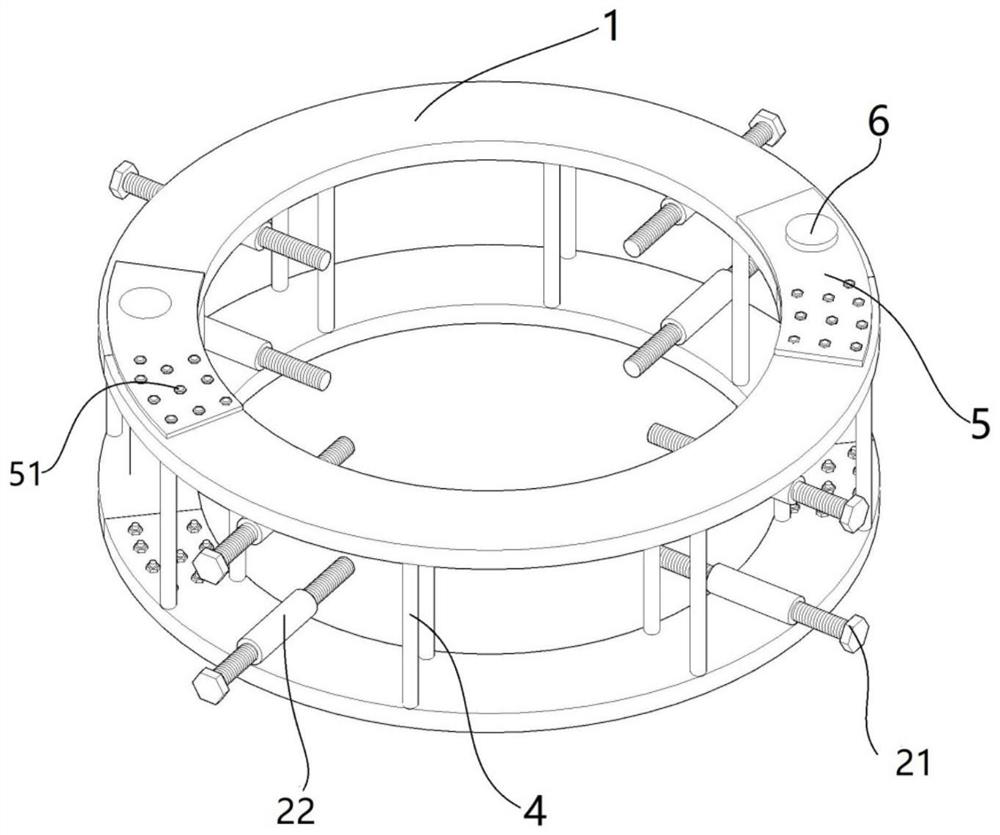

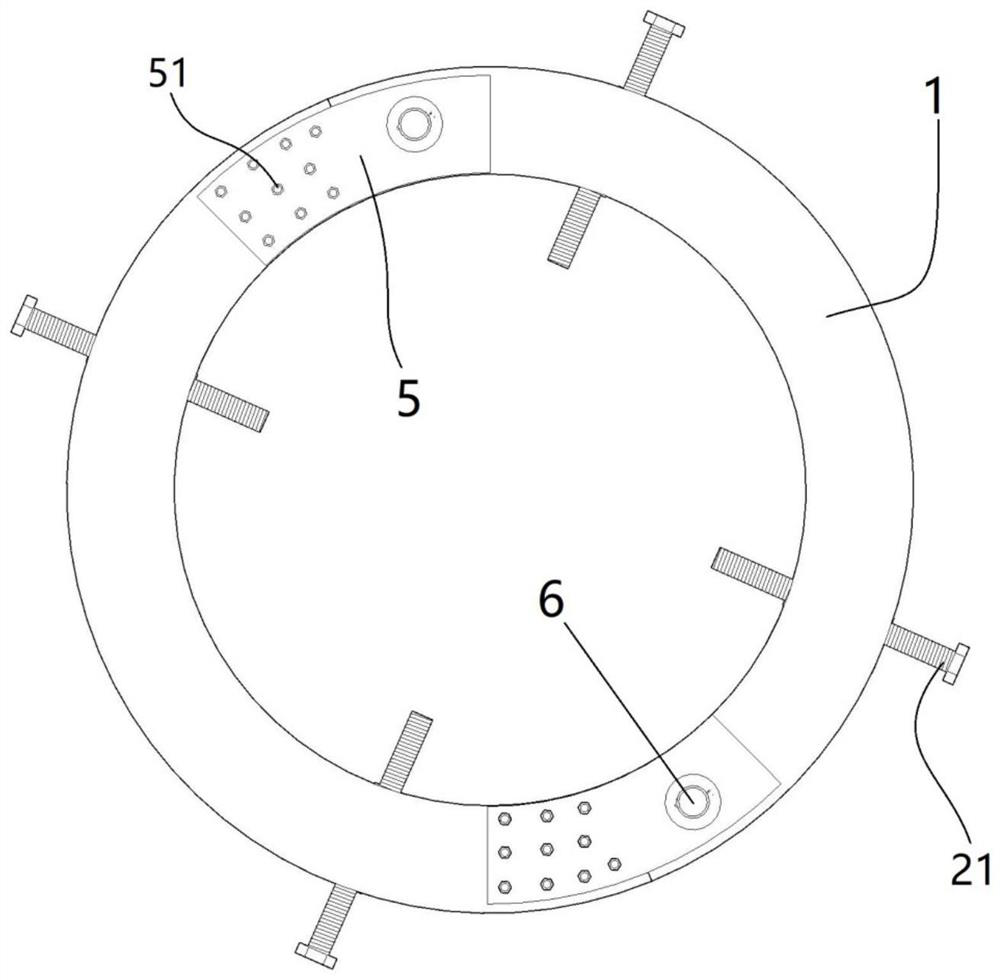

[0044] refer to Figure 1 to Figure 4 , in the first aspect, the present application provides a ring alignment device, including: a ring fixing part 1, which is used to be sleeved on the steel pipe to be aligned; an adjustment mechanism, a plurality of adjustment mechanisms along the ring fixing part 1 The circumferential direction is evenly arranged, and the adjustment mechanism can move along the radial direction of the annular fixing member 1 to clamp the steel pipes that need to be aligned.

[0045] In this embodiment, the ring-shaped fixing part 1 can be sleeved on two steel pipes that need to be aligned, and the two steel pipes that need to be aligned can be fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com