A matcha grinder

A grinding machine and grinding device technology, applied in the field of grinding machines, can solve the problems of stone grinding empty grinding, tea sticking, tea spilling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

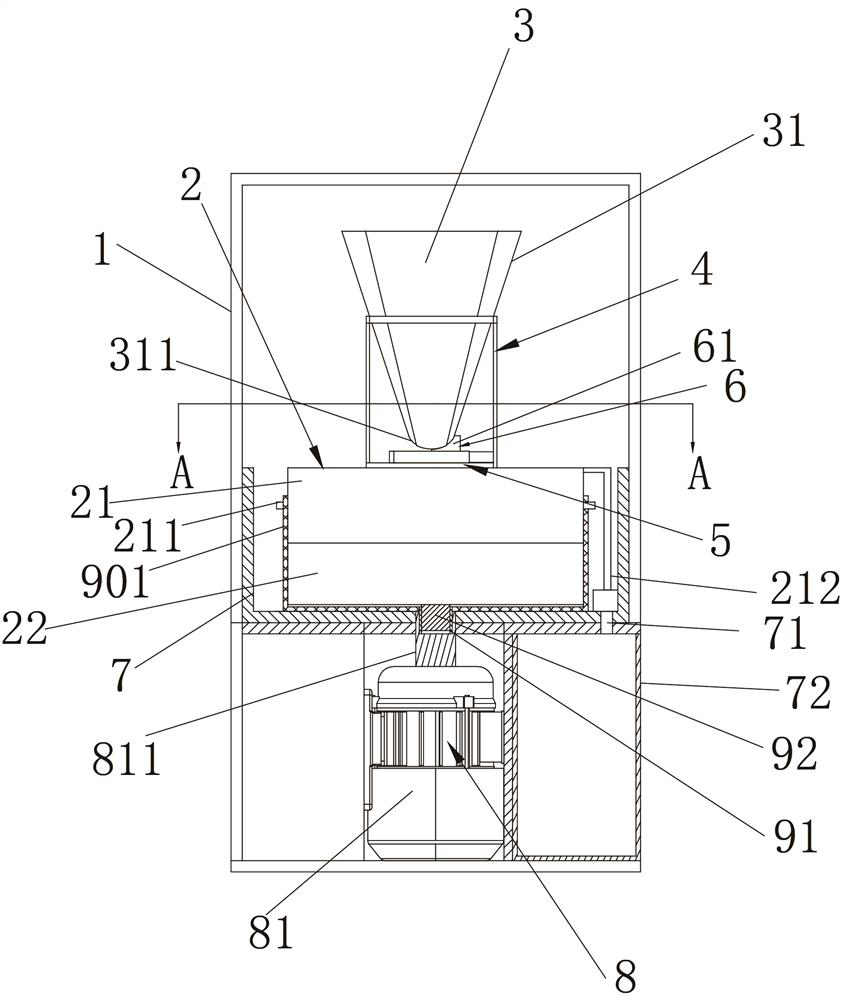

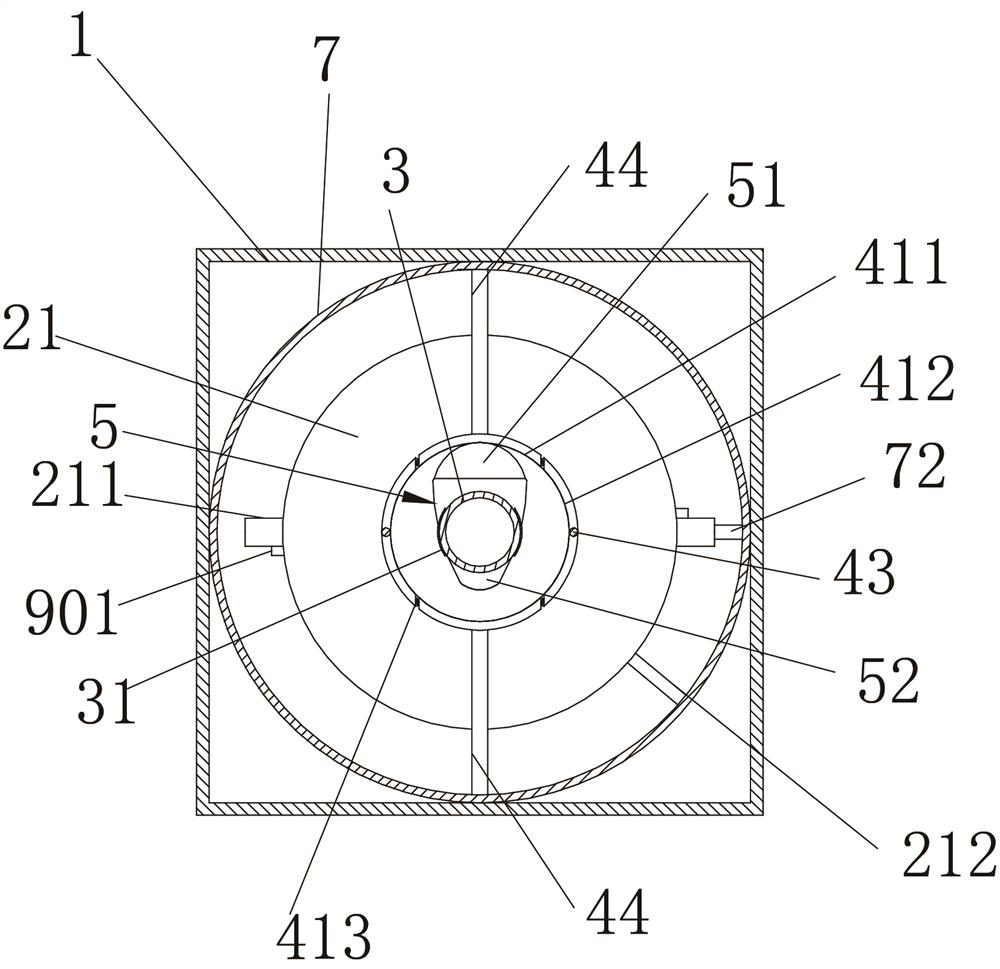

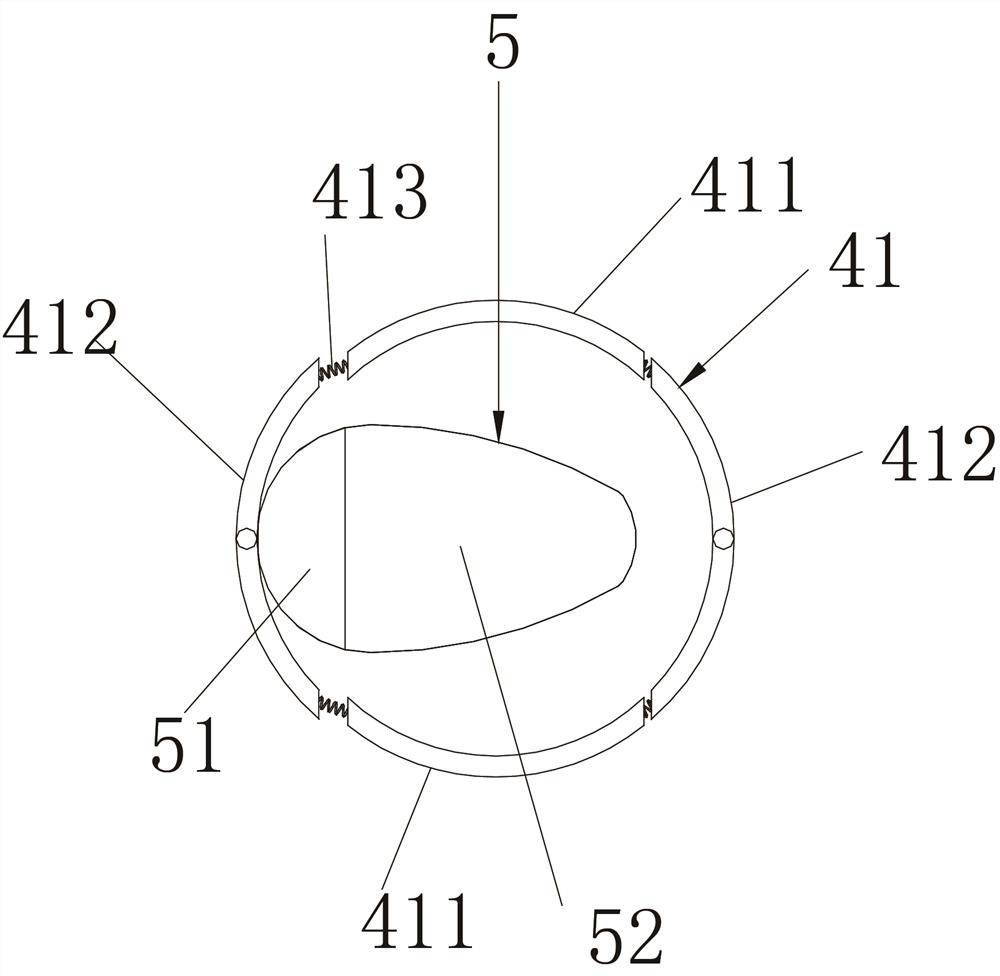

[0021] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1-Figure 6 , a matcha grinder includes a shell 1 and a grinding device 2, the grinding device 2 is arranged inside the shell 1, and the grinding device 2 includes an upper stone mill 21 and a lower stone mill 22, and the upper stone mill 21 is located at Above the lower stone mill 22, an activation device 8 is set in the shell 1 below the grinding device 2.

[0022] The starting device 8 includes a rotating motor 81, the output shaft 811 on the rotating motor 81 is connected to the rotating shaft 9, and the rotating shaft 9 includes an outer sleeve 91 and an inner sleeve 92, and the outer sleeve 91 is rotatably connected to the inner sleeve 92, and the output shaft 811 is connected with the outer cover 91, and the outer cover 91 is connected with the rotating rod 901. When the rotating motor 81 works, the output shaft 811 will dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com