A kind of concrete surface treatment equipment and its surface treatment process

A concrete surface and treatment equipment technology, applied in the field of construction, can solve problems such as increased labor, fluctuations in product quality, failure to meet the requirements of concrete surface treatment, etc., and achieve the effect of improving rubbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

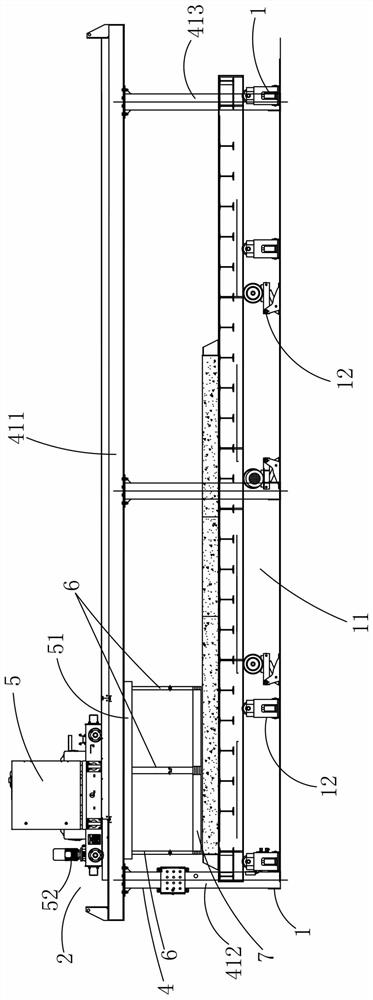

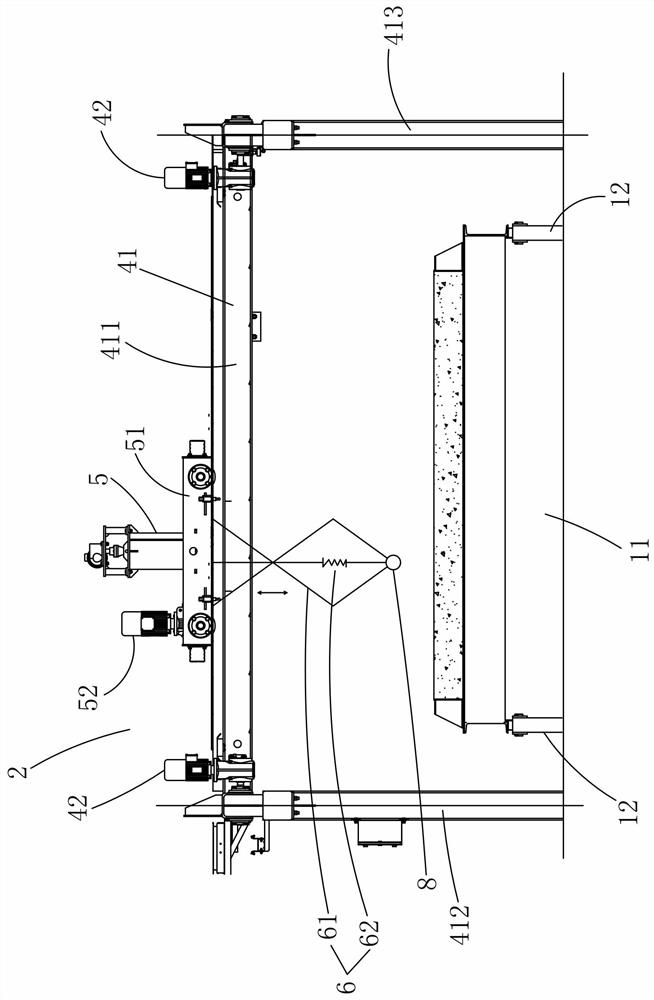

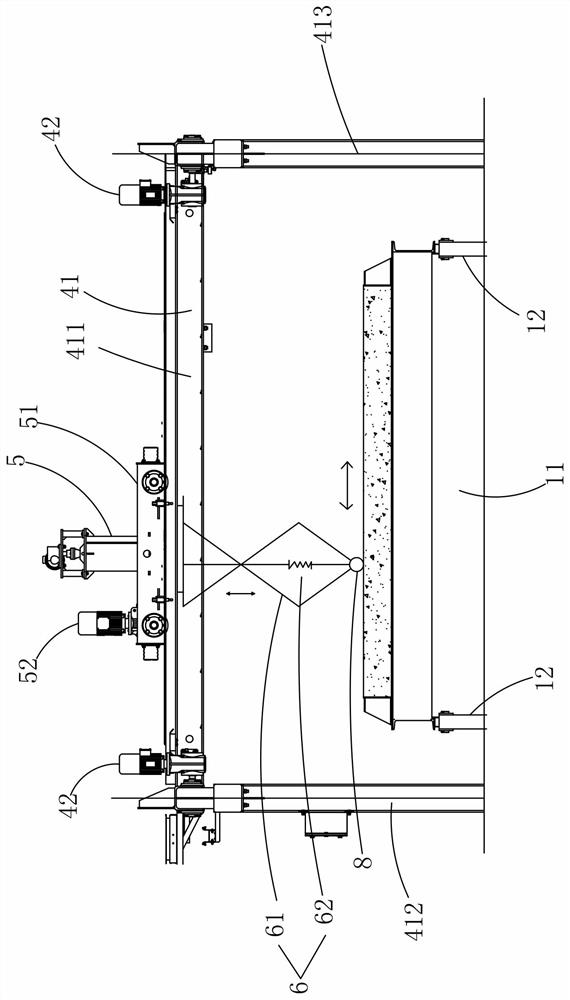

[0037] Example, combined with Figure 1 to Figure 7 As shown, a concrete surface treatment equipment includes a track 1, a moving device 2 and a rubbing device 3.

[0038]The mobile device 2 includes a longitudinal movement mechanism 4 and a lateral movement mechanism 5, the longitudinal movement mechanism 4 includes a bracket 41 and a bracket driving assembly 42, the bracket 41 includes a first leg 412, a second leg 413 and a beam 411, the One end of the beam 411 is connected to the first leg 412, and the other end of the beam 411 is connected to the second leg 413. The first leg 412 and the second leg 413 are respectively seated on the track 1. The bracket drive assembly 42 is connected to the bracket 41, and the bracket The driving assembly 42 drives the bracket 41 to move along the guide rail 1 in the Y-axis direction.

[0039] The lateral movement mechanism 5 includes a sliding bracket 51 and a sliding bracket driving assembly 52, the sliding bracket 51 is seated on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com