Adsorbent for removing protein-bound uremic toxin by hemoperfusion and preparation method thereof

A technology of hemoperfusion and adsorbent, which is applied in the direction of blood circulation treatment, chemical instruments and methods, suction devices, etc., to achieve good adsorption performance, environmental protection, cost reduction, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

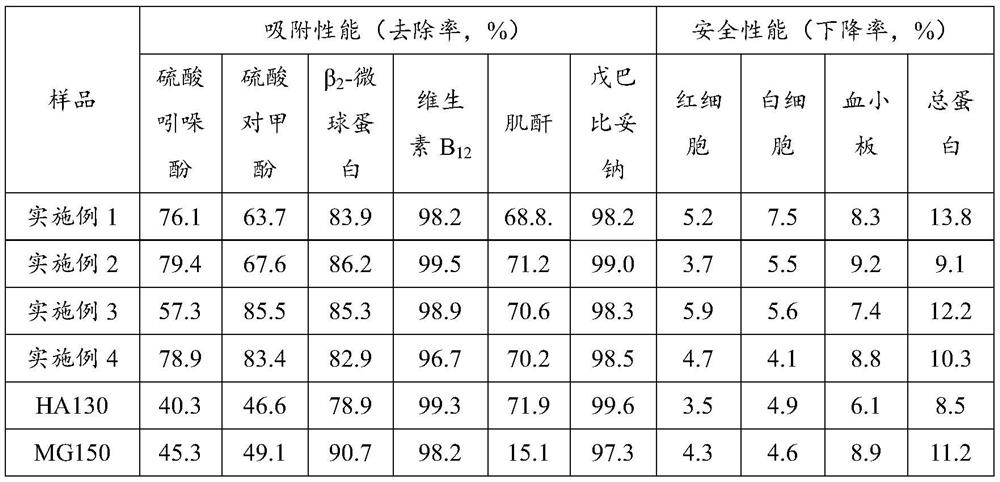

Examples

preparation example Construction

[0077] According to another aspect of the present invention, the present invention also relates to a method for preparing an adsorbent for removing protein-bound uremic toxins by hemoperfusion as described above, comprising the following steps:

[0078] (a) mixing the oil phase and the water phase for polymerization, and obtaining resin A after separation;

[0079] The oil phase includes styrene, acrylonitrile, divinylbenzene, porogen and benzoyl peroxide;

[0080] The aqueous phase comprises gelatin, sodium chloride and water;

[0081] (b) adding concentrated sulfuric acid to the resin A obtained in step (a) for hydrolysis to obtain resin B;

[0082] (c) Mix the ethanol solution of the imprinted molecules, the resin B, 1,2-dichloroethane, and anhydrous ferric chloride to perform a cross-linking-imprinting reaction to obtain a protein-bound uremic drug for hemoperfusion removal. Adsorbents for toxins.

[0083] The preparation method of the invention has simple steps, mild c...

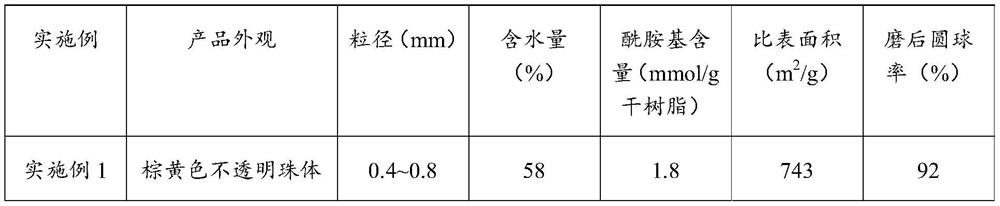

Embodiment 1

[0135] A method for preparing an adsorbent for removing protein-bound uremic toxins by hemoperfusion, comprising the following steps:

[0136] (a) Polymerization reaction: 15 mass parts of styrene, 15 mass parts of acrylonitrile, 70 mass parts of 80% divinylbenzene, 50 mass parts of toluene, 50 mass parts of n-octanol, 1.5 mass parts of Benzoyl oxide (BPO) is uniformly mixed and prepared into an oil phase, and dropped into a pre-prepared water phase containing 1% mass concentration of gelatin and 10% mass concentration of sodium chloride at 50°C, the mass of the water phase and the oil phase The ratio is 4:1; after mixing, let it stand for 10 minutes, start stirring, adjust the particle size to a suitable range, then raise the temperature to 90°C at a rate of 1°C / 2min, and keep it warm for 12h; stop the reaction, drain the polymerization mother liquor, and wash with water at 50°C Resin until the effluent is clear, ethanol extracts the porogen at room temperature and transfers to...

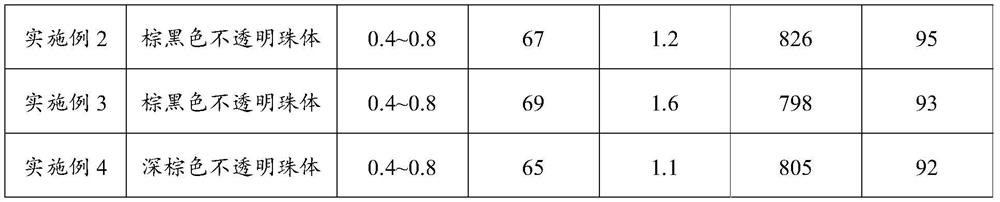

Embodiment 2

[0140] A method for preparing an adsorbent for removing protein-bound uremic toxins by hemoperfusion, comprising the following steps:

[0141] (a) Polymerization reaction: the styrene of 5 mass parts, the acrylonitrile of 5 mass parts, the 80% divinylbenzene of 90 mass parts, the toluene of 100 mass parts, the n-octanol of 50 mass parts, the BPO of 0.5 mass parts Mix them evenly to form an oil phase, and put them into a pre-prepared water phase containing 0.5% mass concentration of gelatin and 5% mass concentration of sodium chloride at 50°C, and the mass ratio of the water phase to the oil phase is 3:1; After mixing, let it stand for 10 minutes, start stirring, adjust the particle size to a suitable range, raise the temperature to 80°C at a rate of 1°C / 2min, and keep it warm for 10h; stop the reaction, drain the polymerization mother liquor, wash the resin with water at 50°C until the effluent is clear, Extract the porogen with ethanol at room temperature, transfer to the wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com