Live pig slaughtering system

A technology of live pigs and steam boxes, applied in slaughtering, slaughtering accessories, slaughtering devices, etc., can solve the problems of high labor intensity, cumbersome operation, and pork affecting the meat, and achieve the effects of reducing the use of labor, improving practicability, and increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

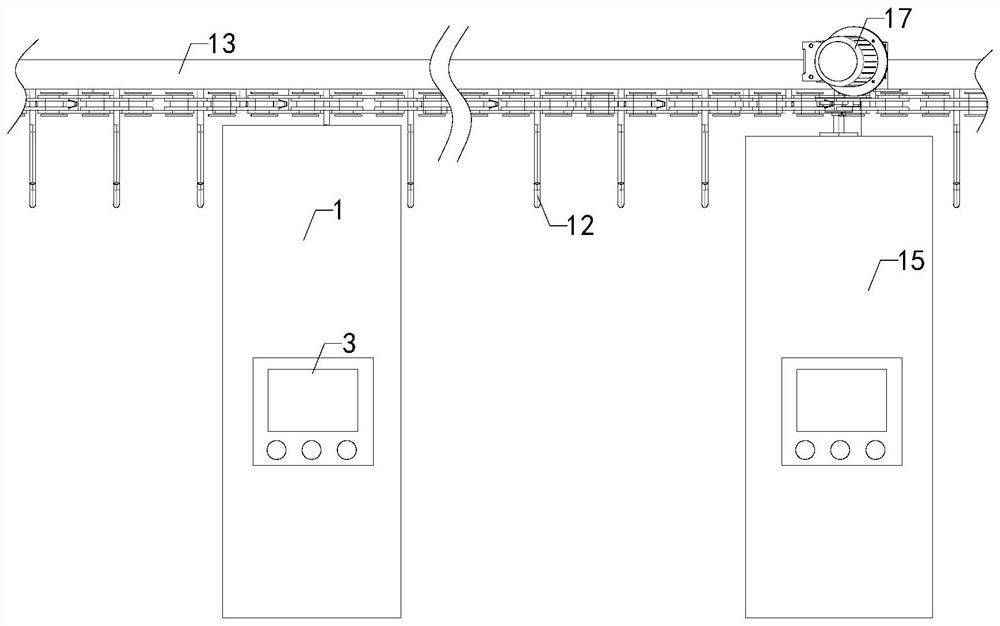

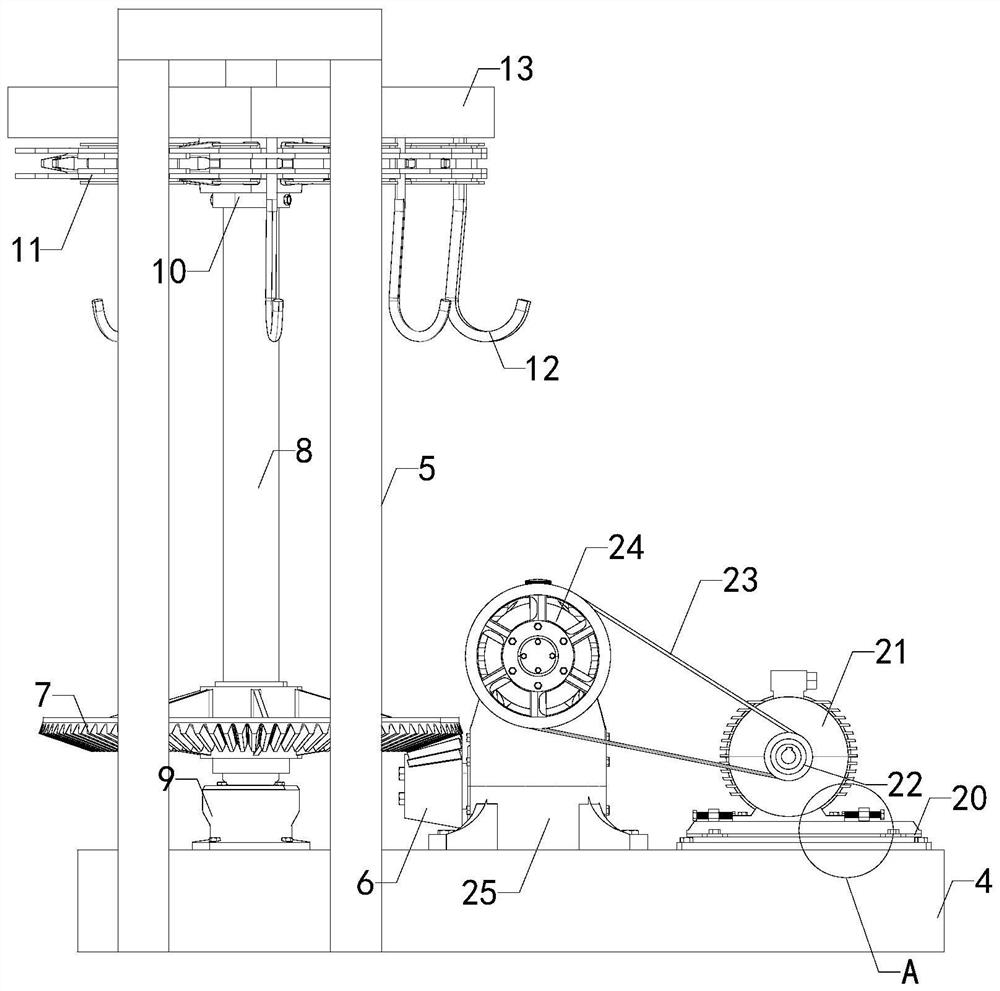

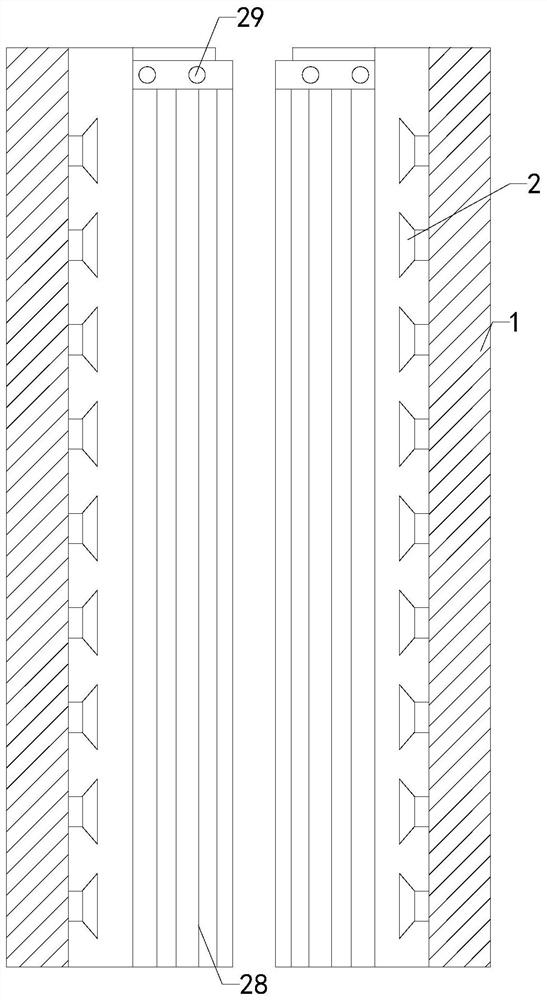

[0022] like Figure 1 to Figure 7 As shown, a pig slaughtering system of the present invention includes a steam box 1, a high-pressure steam nozzle 2, a bottom plate 4, a stand 5, an incomplete bevel gear 6, a complete bevel gear 7, a first rotating shaft 8, a bearing seat 9, a chain Wheel 10, chain 11, hook 12, guide mechanism, hair removal mechanism, power mechanism and adjustment mechanism, steam box 1 is provided with a control panel 3, several groups of high-pressure steam nozzles 2 are respectively installed inside two groups of steam boxes 1, stand 5 is fixedly installed on the bottom plate 4, the power mechanism is installed on the bottom plate 4, the incomplete b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com