Online analytical instrument system

An analytical instrument and fixed plate technology, applied in the field of online analysis, can solve problems affecting online analysis, and achieve the effect of real-time monitoring of process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

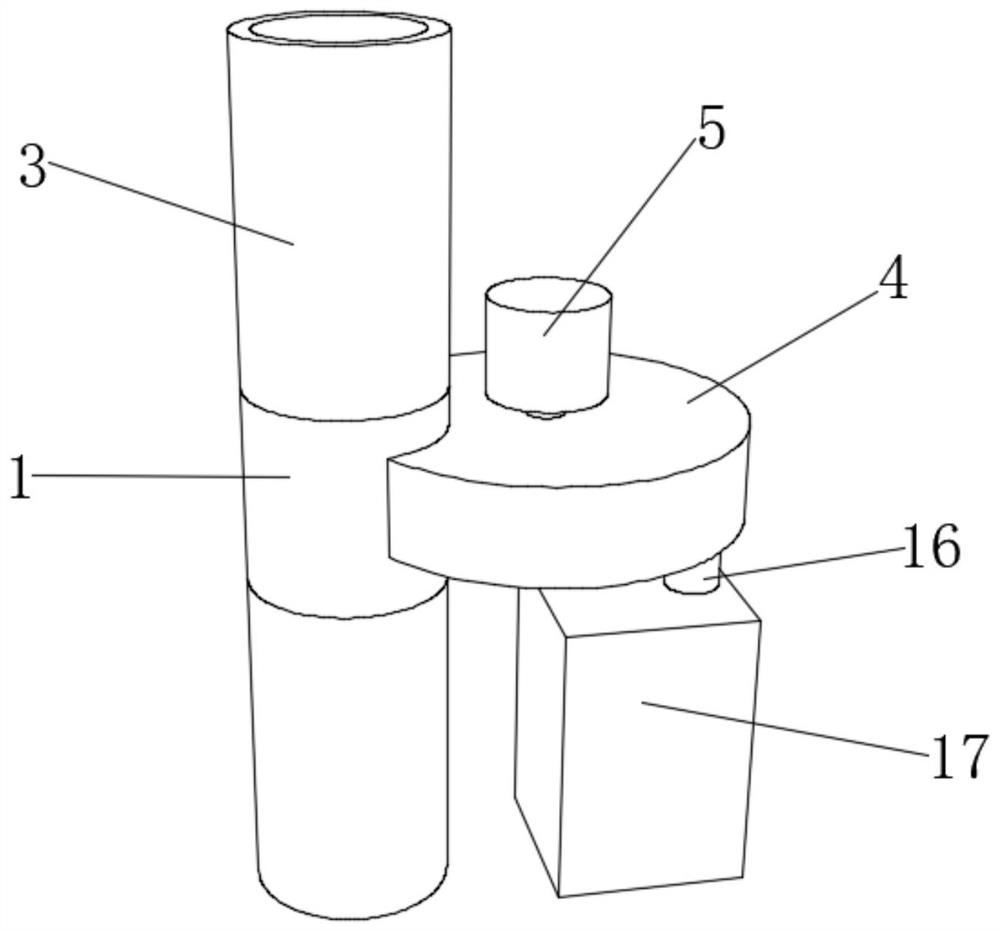

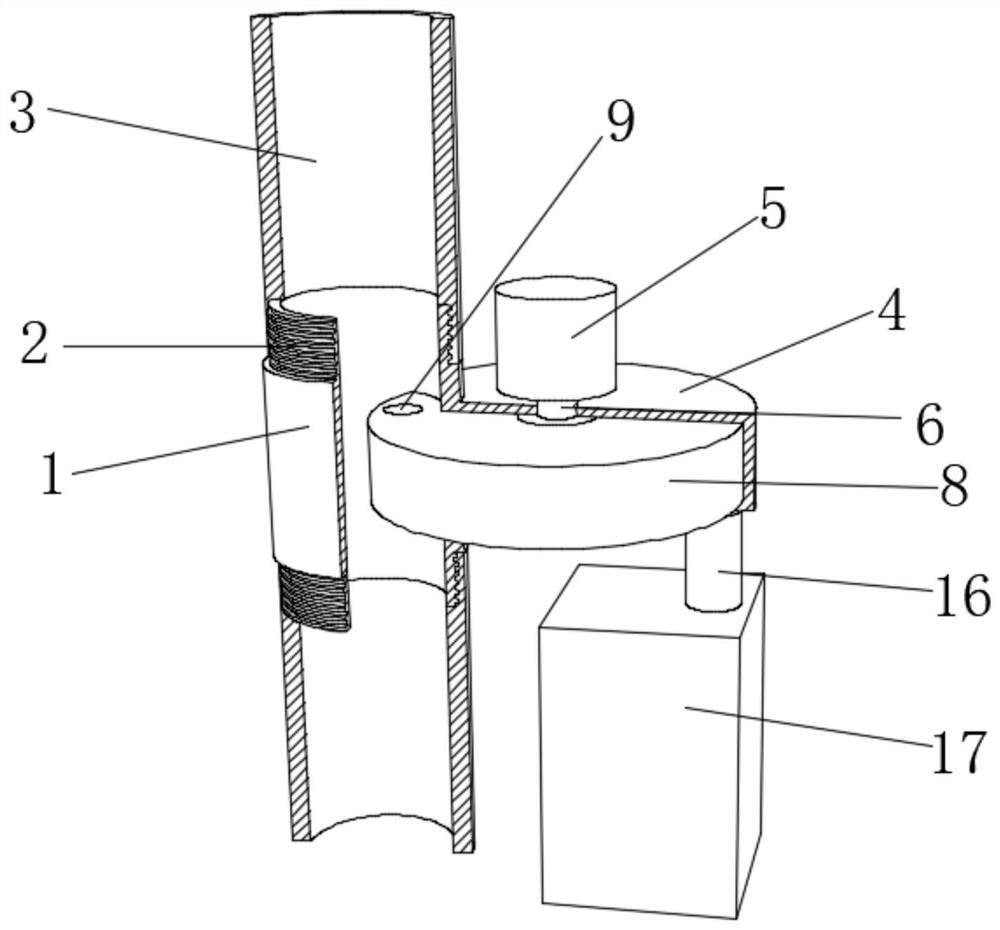

Image

Examples

Embodiment approach

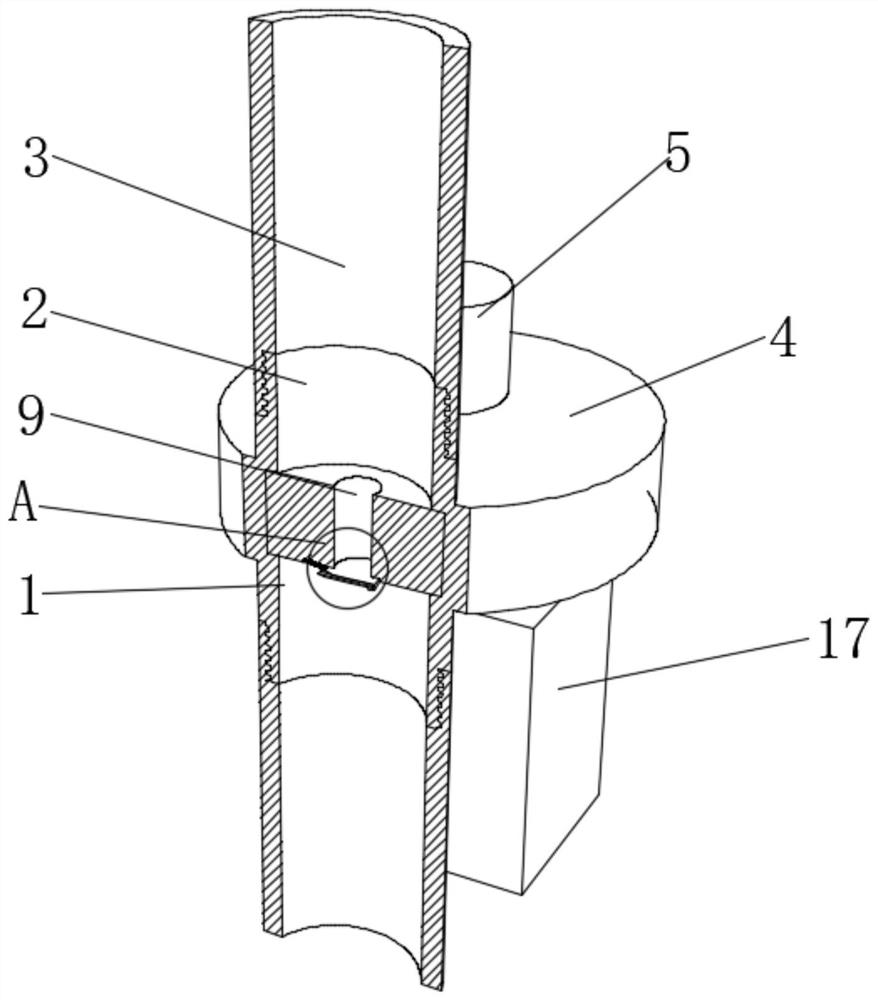

[0025] The embodiment is specifically as follows: the rotating disk 8 can drive the sampling hole 9 to rotate, and the sampling hole 9 passes through the first connecting pipe 1 at a fixed frequency after rotating, and when the sampling hole 9 passes through the first connecting pipe 1, the first connecting pipe 1 internally transports The reactant flows into the inside of the sampling hole 9, and the sealing plate 10 can seal the bottom of the sampling hole 9, so that the reactant will not flow out from below. The sliding bar 11 can facilitate the movement of the sealing plate 10, and the soft rubber strip 12 is rotated to the inclined position. When the groove 14 is at the position, it squeezes and rubs against the inclined groove 14, so that the soft rubber strip 12 drives the sealing plate 10 to squeeze and slide toward the spring 13, thereby opening the bottom of the sampling hole 9, so that the reactants inside the sampling hole 9 pass through. The through hole 15 inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com