Intelligent quenching equipment for cast iron

A kind of quenching equipment, intelligent technology, applied in the direction of quenching equipment, heat treatment equipment, improving energy efficiency, etc., to achieve the effect of easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

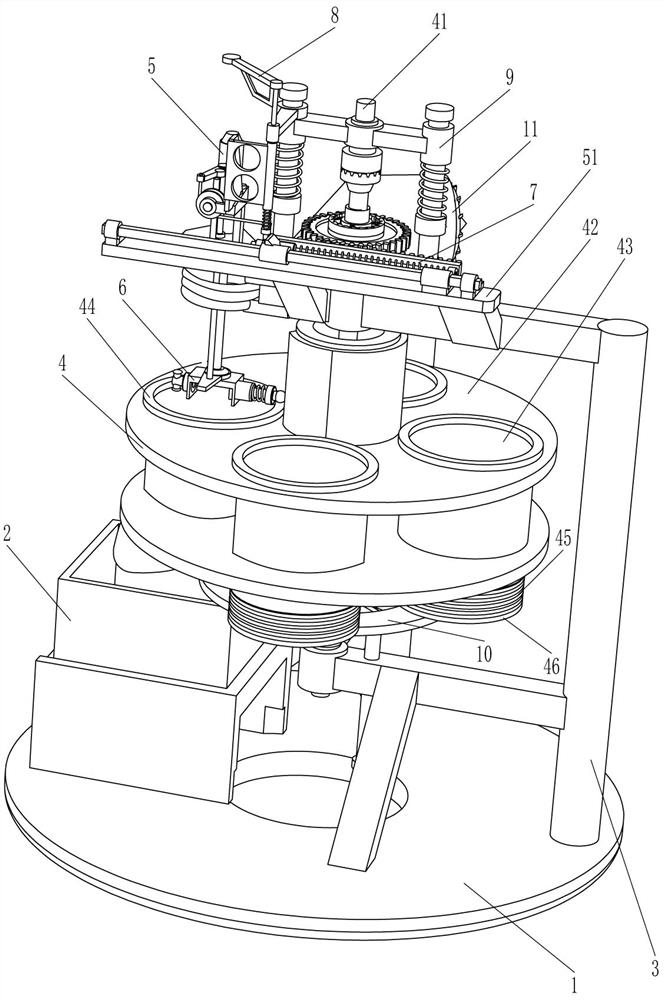

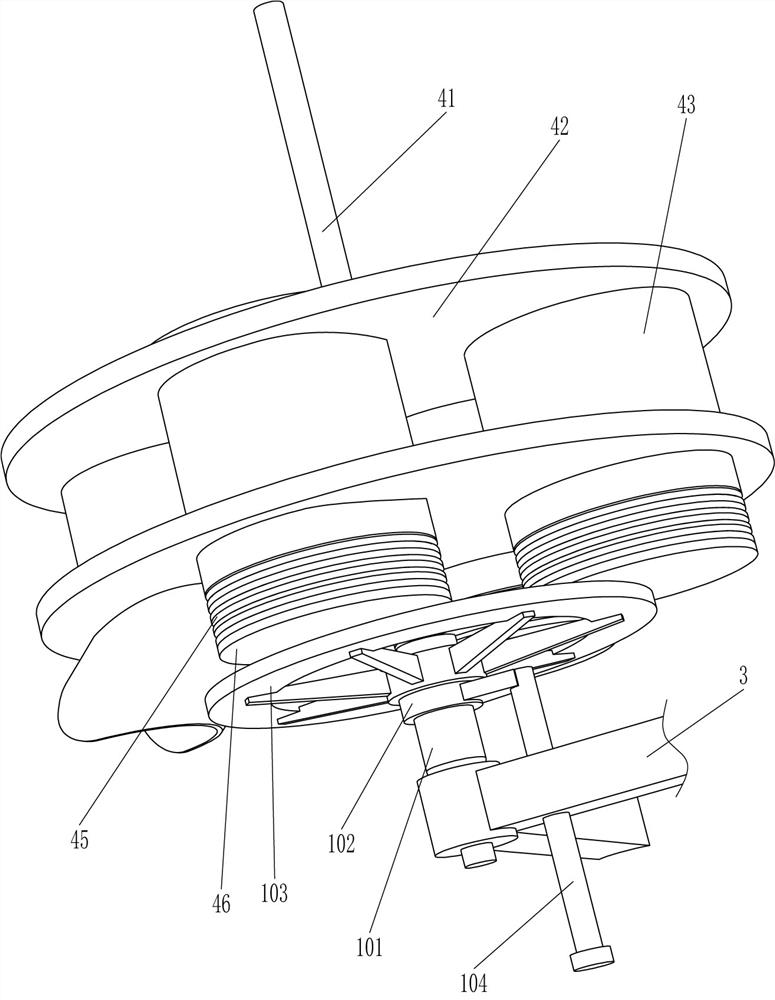

[0029] An intelligent quenching equipment for cast iron, such as figure 1 , figure 2 , image 3 , Figure 4 and Image 6 As shown, it includes a base 1, a collection frame 2, a mounting frame 3, a replacement mechanism 4, a lifting mechanism 5, a clamping mechanism 6, and a driving mechanism 7. The collection frame 2 is placed on the left side of the base 1, and the mounting frame is provided on the base 1. 3. The installation frame 3 is provided with a replacement mechanism 4 in a rotating manner, the installation frame 3 is provided with a lifting mechanism 5, the lifting mechanism 5 is provided with a clamping mechanism 6, and the lifting mechanism 5 is provided with a driving mechanism 7.

[0030] When people need to use this equipment, first people loosen the clamping mechanism 6, and place the iron block between the clamping mechanisms 6, then make the clamping mechanism 6 clamp the iron block, and at the same time, people enter the replacement mechanism 4 Add diffe...

Embodiment 2

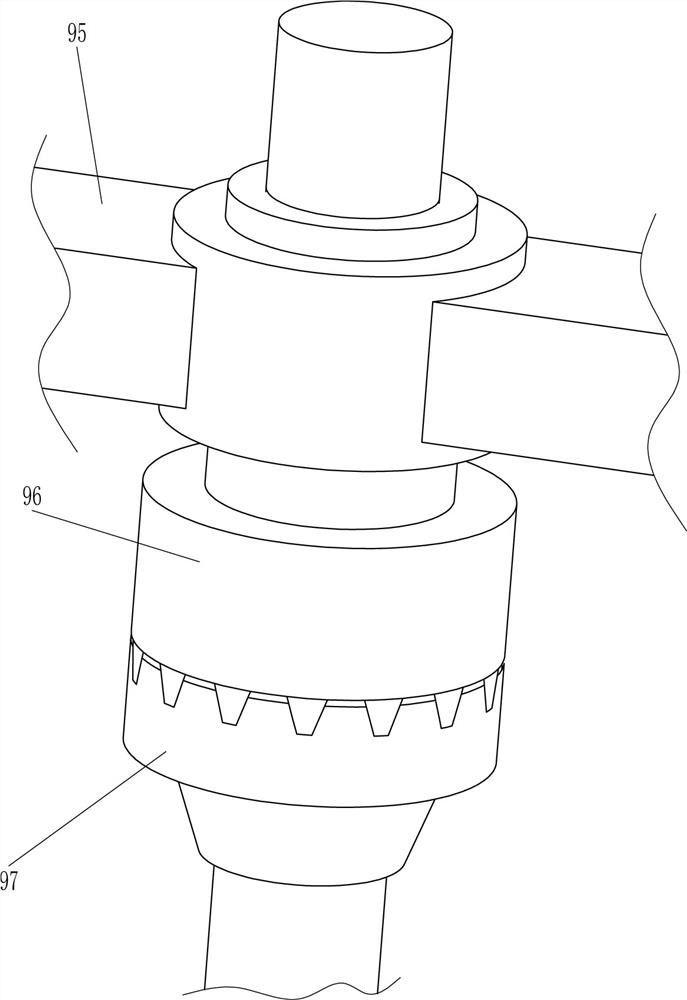

[0037] On the basis of Example 1, such as figure 1 , figure 2 , Figure 4 , Figure 5 , Image 6 and Figure 7 As shown, it also includes a locking mechanism 8. The locking mechanism 8 includes a wedge block 81, a guide tube 82, a locking lever 83, a third spring 84 and a contact frame 85. A wedge is provided between the first sliding sleeve 77 and the square hole sleeve 75. Block 81, special-shaped frame 55 is provided with guide tube 82, and guide tube 82 slide type is provided with locking bar 83, and locking bar 83 cooperates with wedge block 81, is provided with the 3rd spring 84 between locking bar 83 and guide tube 82, A contact frame 85 is arranged on the locking rod 83 , and the contact frame 85 cooperates with the driving rod 71 .

[0038] In the initial state, the locking rod 83 blocks the wedge block 81, so that when the driving rod 71 moves upwards, the pull cord 72 pulls the first sliding rod 78 to move to the left, and the second spring 79 is compressed, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com