Antibacterial flexible cover plate and preparation method thereof

A flexible cover and flexible substrate technology, applied in biocide-containing paints, coatings, anti-fouling/underwater coatings, etc., can solve the problem of difficult performance of flexible cover plates, inability to guarantee surface hardness, affecting light transmission performance, etc. problem, achieve the effect of increasing light transmittance, enhancing stability and adhesion ability, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

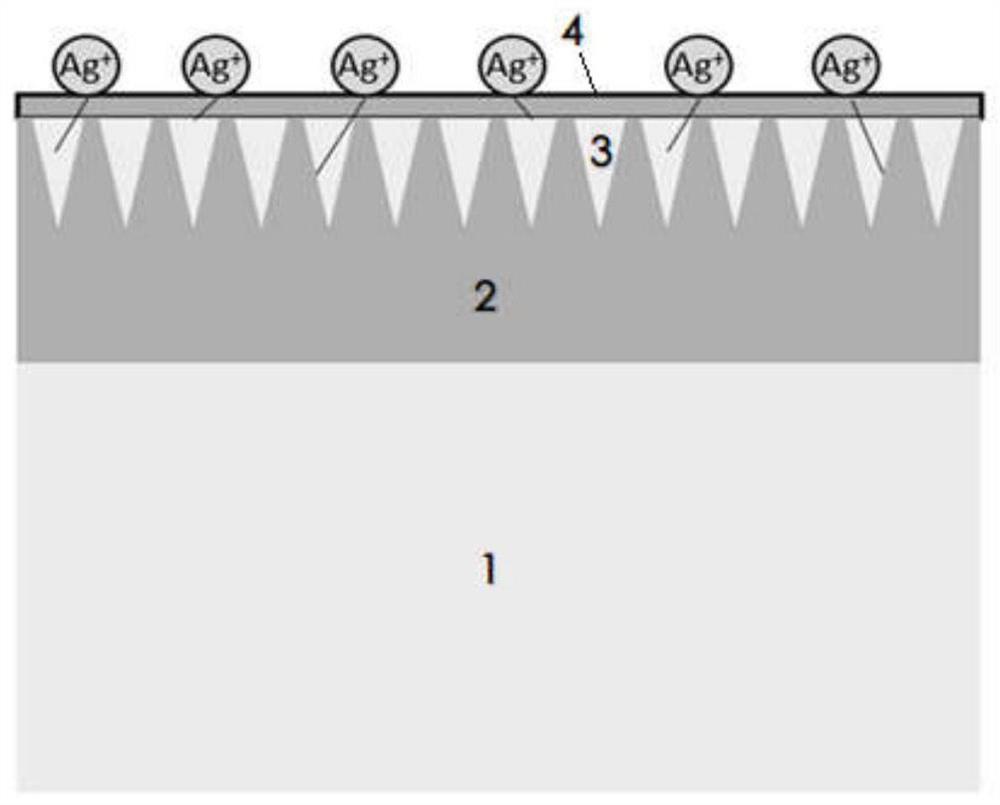

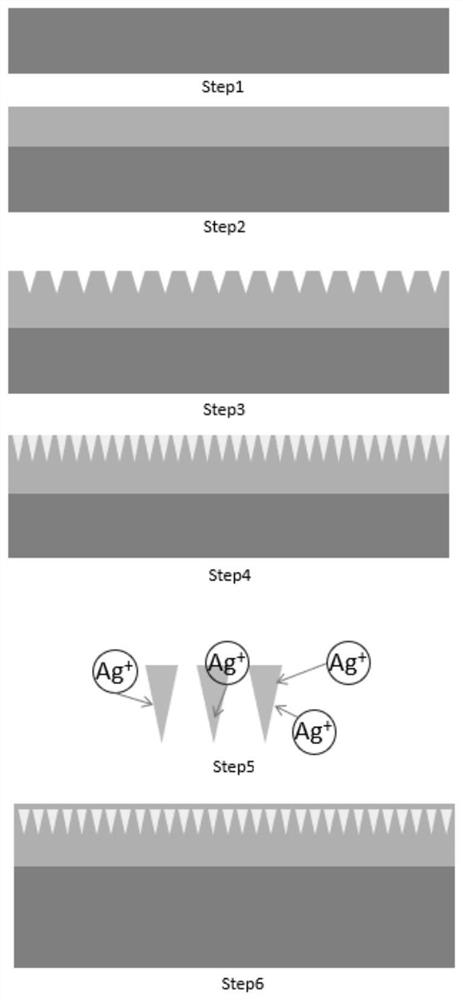

[0027] Embodiment 1 of the present invention: as figure 1 As shown, an antibacterial flexible cover:

[0028] The order is a transparent flexible polyimide film substrate; the first hardened layer, with a thickness of 8 μm; the nanohole array antibacterial layer, with a nanopore depth of 6 μm; the second hardened layer, with a thickness of 1 μm; the first hardened layer and the second hardened layer are made of polyurethane Acrylic acid ester (PUA) resin 100 mass parts and silicon dioxide 15 mass parts are made; Nanopore array antibacterial layer is to fill resin material in nanopore array and make, and described resin material is made of polyurethane acrylate resin 10 molar parts, containing The silver nitrate solution with 5 molar parts of amino functional group resin and the concentration of 1g / L and the swelling solvent isopropanol are made, and the addition of isopropanol is 10% of the solvent water quality in the silver nitrate solution.

Embodiment 2

[0029] Embodiment 2: as figure 1 As shown, an antibacterial flexible cover:

[0030] The order is a transparent flexible polyacrylonitrile substrate; the first hardened layer, with a thickness of 15 μm; the nanohole array antibacterial layer, with a nanopore depth of 13 μm; the second hardened layer, with a thickness of 2 μm; the first hardened layer and the second hardened layer are made of polyurethane acrylate (PUA) resin 100 mass parts and silicon dioxide 20 mass parts are made; Nanohole array antibacterial layer is to fill resin material in nanohole array and make, and described resin material is made of polyurethane acrylate resin 20 molar parts, containing mercapto functional group 10 mole parts of resin, silver nitrate solution with a concentration of 1 g / L and swelling solvent acetone are prepared, and the amount of acetone added is 30% of the solvent water quality in the silver nitrate solution.

Embodiment 3

[0031] Embodiment 3: as figure 1 As shown, an antibacterial flexible cover:

[0032] The order is a transparent flexible polyethylene terephthalate substrate; the first hardened layer with a thickness of 5 μm; the nanohole array antibacterial layer with a nanopore depth of 3 μm; the second hardened layer with a thickness of 2 μm; the first hardened layer and the second hardened layer The layer is made of 100 parts by mass of polyurethane acrylate (PUA) resin and 10 parts by mass of silicon dioxide; the nanohole array antibacterial layer is made of a resin material filled in the nanohole array, and the resin material is made of 20 moles of polyurethane acrylate resin parts, 10 molar parts of resin containing amino functional groups, a concentration of 1g / L silver nitrate solution and swelling solvent alcohol to make, the alcohol addition is 20% of the solvent water quality in the silver nitrate solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com