Method for rectifying thionyl chloride

A technology of thionyl chloride and sulfur monochloride, which is applied in the direction of thionyl chloride, sulfur and halogen compounds, etc., can solve the problem of increased circulation of thionyl chloride, increased consumption of molten sulfur, easy blockage of rectification towers, etc. problems, achieve the effect of reducing the reflux consumption of finished products, reducing the cost, and enhancing the effect of stripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

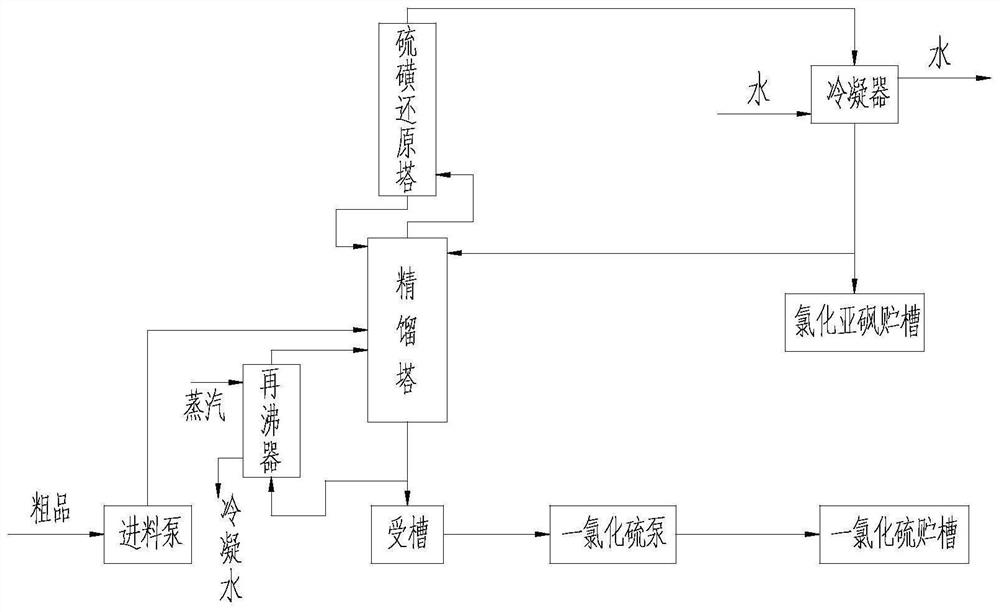

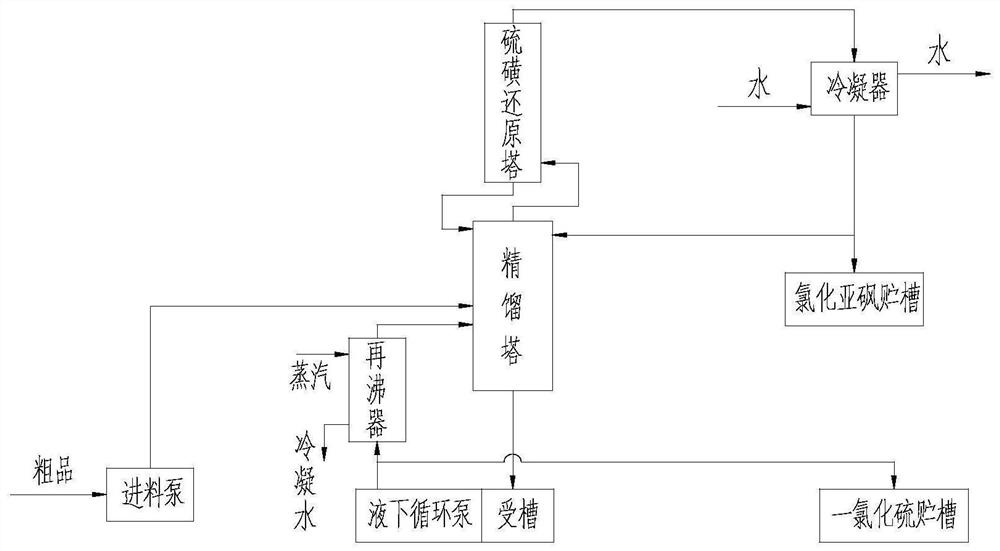

[0023] Such as figure 2 As shown, the inlet of the feed pump is connected to the crude product source pipe, and the outlet of the feed pump is connected to the middle of the rectification column. There are six pipe connections on the rectification tower, which are the pipe connection to the feed pump (connected to the outlet of the feed pump in the middle of the rectification tower), and the inlet pipe connection to the sulfur reduction tower (at the top of the rectification tower, connected to the steam inlet pipe at the lower part of the sulfur reduction tower), connected to the outlet pipe port of the sulfur reduction tower (connected to the sulfur chloride liquid outlet port at the bottom of the sulfur reduction tower at the upper part of the rectifying tower), connected to the outlet pipe port of the condenser ( In the upper part of the rectification tower, it is connected with the liquid outlet pipe of thionyl chloride on the cold side of the condenser), connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com