Intelligent palletizing end effector

A technology of end picker and smart code, which is applied in the field of manipulators, can solve the problems of material bags falling and grip loosening, and achieve the effects of preventing material bags from falling, increasing reliability, and optimizing structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]In order to make the objects, technical solutions and advantages of the present invention, the present invention will be described in detail below with reference to the accompanying drawings and specific examples.

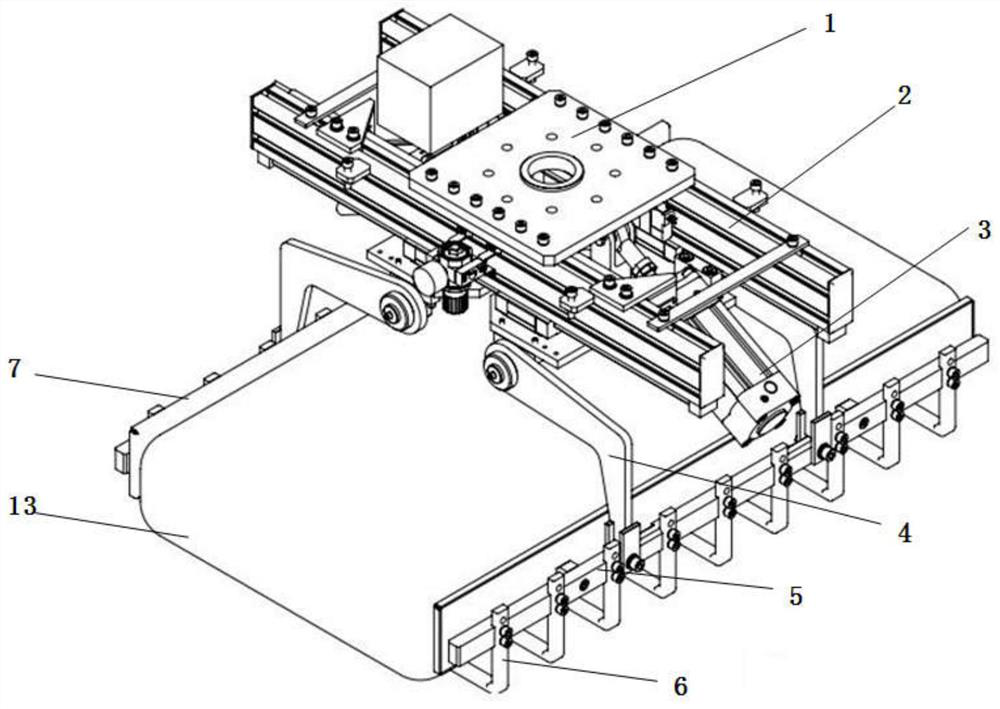

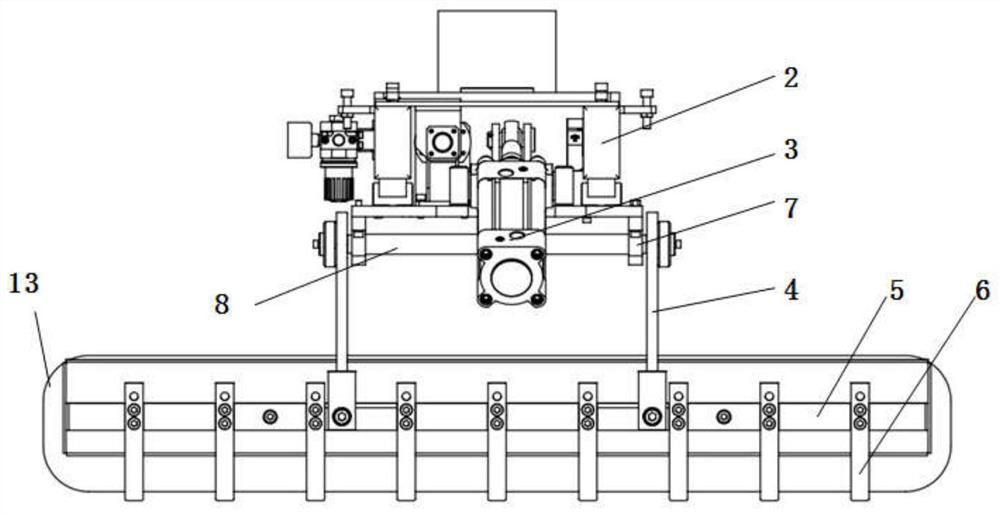

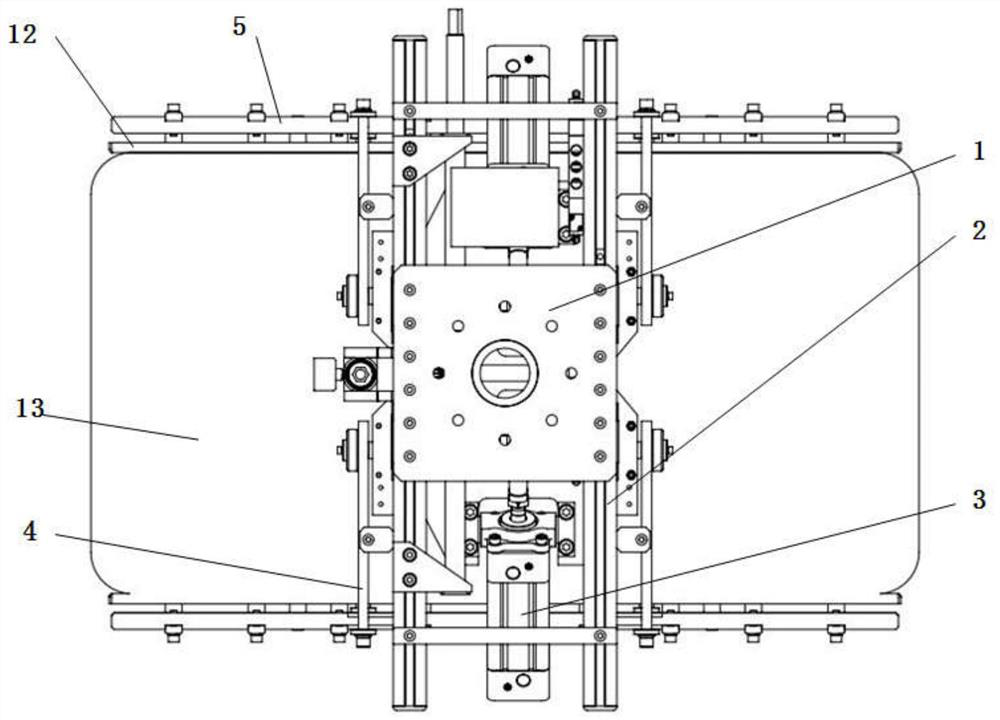

[0030]Such asFigure 1-4As shown, the intelligent procrastinating end supplied by the present invention, including mounting frame 2, rotating shaft 8, left hand grab, right-handed, rotating the drive mechanism, wherein the mounting frame 2 passes through the flange connection plate 1 and the wrist end unit of the robot. Connecting, two mounting frames 2 can be rotatably mounted, and the rotating shaft 8 is connected to the bearing 6 6 through the bearing and fixed to the mounting frame 2, and the left hand grabs and the right hand can be connected to the two rotary shafts 8, respectively. The rotating drive mechanism is disposed on the mounting frame 2, and the output terminal is connected to the two rotating shafts 8, and the rotational drive mechanism is used to driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com