A Method for Determining Water Level of Balanced Critical Point of Vertical Ship Lift

A vertical ship lift and a technology to determine the method, applied in the field of ship lift, to achieve the effect of efficient and convenient mounting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

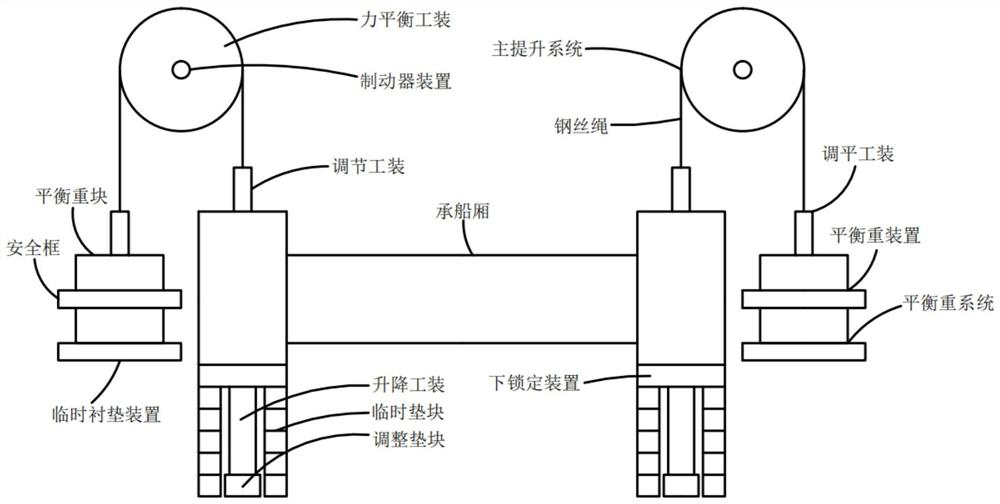

[0067] combined with figure 1 , the present embodiment proposes a method for determining the water level at the critical point of vertical ship lift equilibrium, including the following steps:

[0068] 1) Carry out the installation of the main hoisting system, the carrying box and the counterweight system;

[0069] 2) Carry out no-load leveling of the vessel;

[0070] 3) Carry out the water injection operation of the ship-carrying compartment: inject water into the vessel-carrying compartment until the total weight of the vessel-carrying compartment and the total weight of the counterweight system reach a balance;

[0071] 4) Carry out the static leveling of the carrying box and the counterweight system;

[0072] 5) Mark the water level in the vessel: the water level in the vessel is the water level at the critical point of vertical ship lift equilibrium.

[0073] First, the main hoisting system is mounted with the counterweight system and the carrier box respectively, so tha...

Embodiment 2

[0098] This embodiment proposes a method for determining the water level at the critical point of vertical ship lift equilibrium, which can be improved as follows on the basis of Embodiment 1: Step 1-2) includes:

[0099] The mounting of the counterweight system and the main lifting system includes:

[0100] Adjust the leveling tool on the upper side of the counterweight device to the middle of the stroke;

[0101] Fix the wire rope to the leveling tool;

[0102] Adjust the leveling tool so that the counterweight remains level after being lifted.

[0103] The adjusting screw can be selected as the leveling tool, and the elongation of the adjusting screw is adjusted to the middle position of the screw stroke to provide a margin for subsequent adjustment, and the wire rope and the leveling tool can be fixedly connected to realize the fixation of the balance weight system and the main lifting system. After connection, the self-level adjustment of the counterweight device when i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com