Multi-layer material arc-shaped cutting method

A multi-layer material, arc-shaped technology, applied in chemical instruments and methods, lamination, lamination devices, etc., can solve the problems of poor cutting effect, waste entering the main line of the product, easy relaxation or rolling of the material layer, etc. Cut-off effect, avoid slack or rollover, prevent over-bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

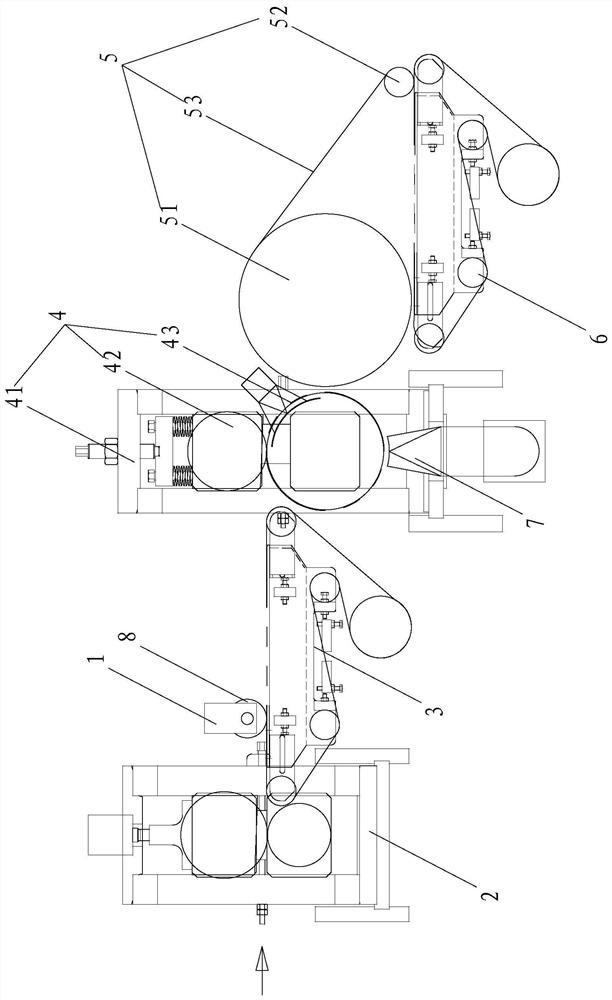

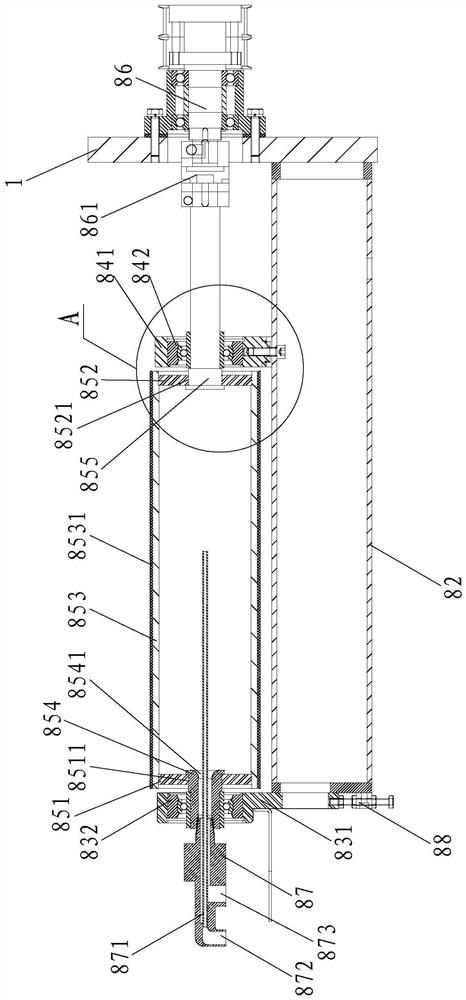

[0032] refer to figure 1 , the present embodiment provides a multi-layer material arc cutting device, including a frame 1 and a thermal pressing device 2 arranged on the frame 1 according to the assembly line, a first adsorption conveying device 3, an arc cutting device 4, and a transfer wheel device 5. The transfer wheel device 5 includes an adsorption wheel 51 rotatably arranged on the frame 1, an adsorption wheel driving mechanism (not shown in the figure) for driving the rotation of the adsorption wheel 51, and an attachment wheel arranged on the frame 1. The driven wheel 52 and the mesh belt 53 wrapped in the adsorption wheel 51 and the driven wheel 52, the lower end surface of the mesh belt 53 is in a horizontal state, and the frame 1 is provided with a transfer wheel below the mesh belt 53. Device 5 realizes the second adsorption conveying de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com