Building board mounting robot

A technology for building panels and robots, which is applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of unstable center of gravity of mechanical structures, complex installation end structures, top-heavy mechanical arms, etc., and achieve high load-to-weight ratio and flexible use methods , the effect of large carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention will be further explained below in conjunction with the embodiments and accompanying drawings, but it is not intended to limit the protection scope of the present application.

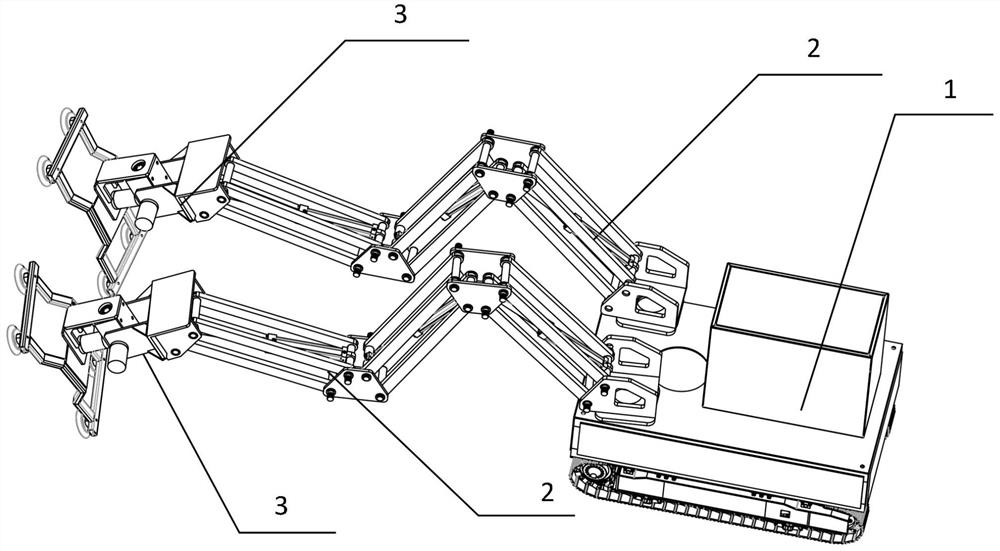

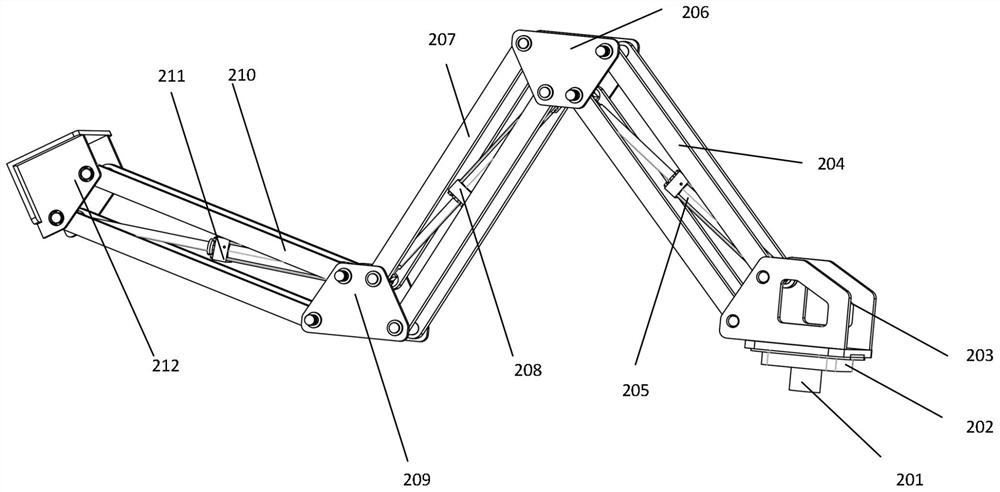

[0035] like figure 1 Shown, the present invention is a kind of building plate installation robot (abbreviation robot, see Figure 1-5 ), including a base 1, a mechanical arm 2 and an installation end 3, two mechanical arms 2 are installed on the base 1, and the end of each mechanical arm 2 is connected with an installation end 3;

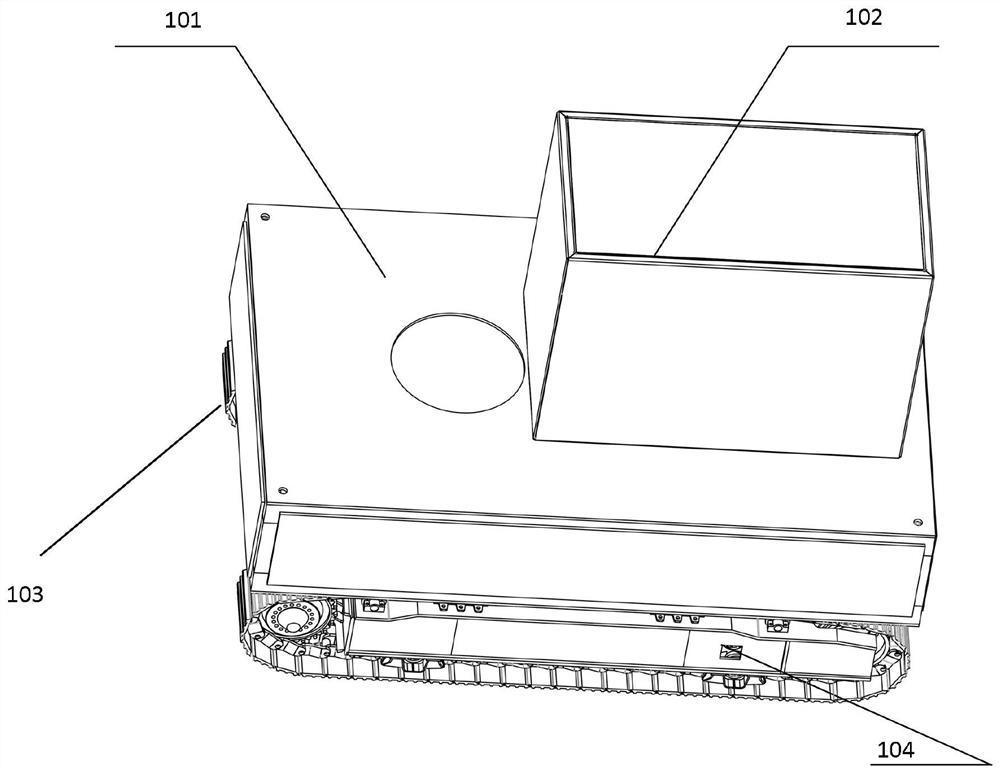

[0036] like figure 2As shown, the base 1 includes a base body 101, a control cabinet 102, a left track wheel set 103 and a right track wheel set 104; the left track wheel set 103 and the right track wheel set 104 are installed on both sides of the bottom of the base body 1, and the robot The oil supply equipment of all the hydraulic cylinders is installed on the base body 1, which increases the stability of the robot;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com